Die-casting die for motor casings

A technology for die-casting molds and motor shells, applied in the field of mold manufacturing, can solve the problems of difficult control of working temperature, alloy liquid casting temperature, casting speed, residence time, etc., to facilitate mechanical operation and automatic control, solve shrinkage cavity, and process yield. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

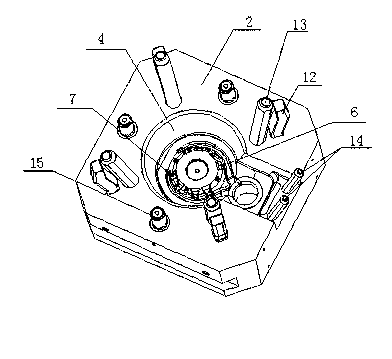

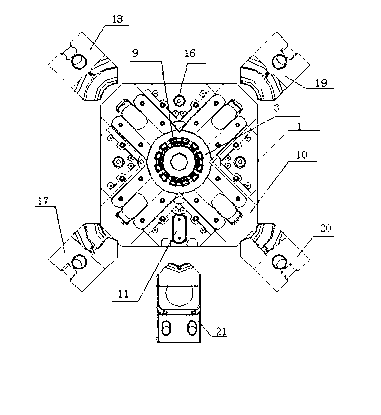

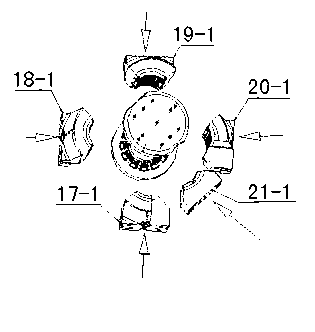

[0018] Depend on figure 1 As we know, the motor housing die-casting mold includes a movable mold frame 1, a fixed mold frame 2, a forming part, and a core-pulling mechanism; the forming part has a movable mold 3, a fixed mold 4, and five side cores Ⅰ17-1, Ⅱ18 -1, Ⅲ19-1, Ⅳ20-1, Ⅴ21-1, which is the cavity 5 of the motor shell mold; the core pulling mechanism has guide chute 10, T-shaped guide rail 11, wedge block 12, large inclined guide post 13, The small inclined guide column 14 and five side sliders Ⅰ17, Ⅱ18, Ⅲ19, Ⅳ20, Ⅴ21 together form the forming part and are installed on the movable mold frame 1 and the fixed mold frame 2, and the movable mold frame 1 and the fixed mold frame 2 have mold guides mechanism, the five side cores are respectively installed on five side sliders, and each side slider is matched with the corresponding T-shaped guide chute 10 on the movable mold 3, and can slide in the groove, and the core-pulling mechanism The core pulling is completed through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com