Upright post structure

A column and vertical plate technology, applied in the direction of claw arms, large fixed members, metal processing machinery parts, etc., can solve the problems of low space utilization, poor assembly process, high space utilization, etc., to improve space utilization and increase compactness degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

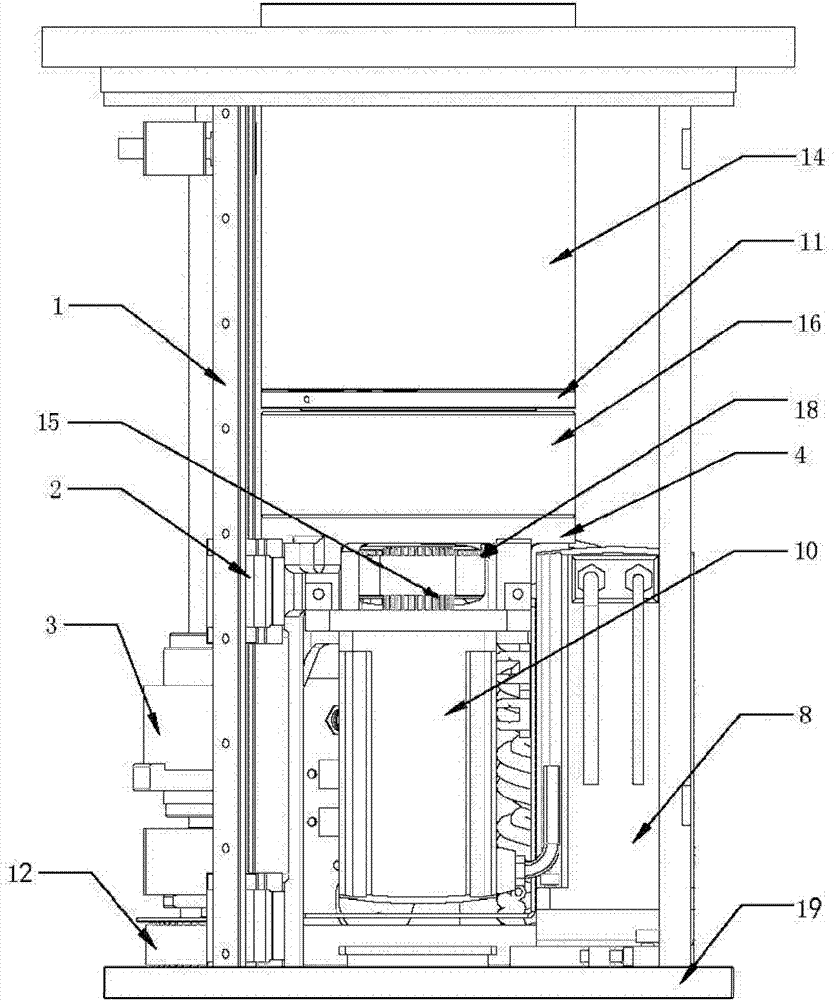

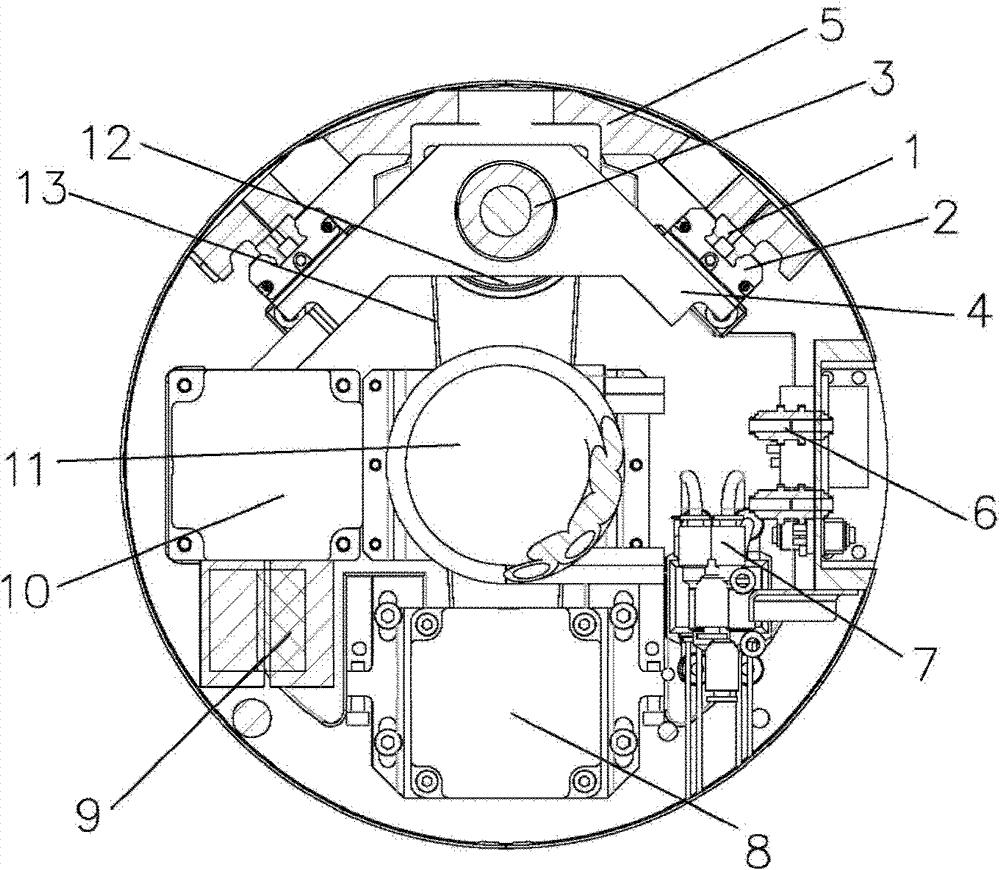

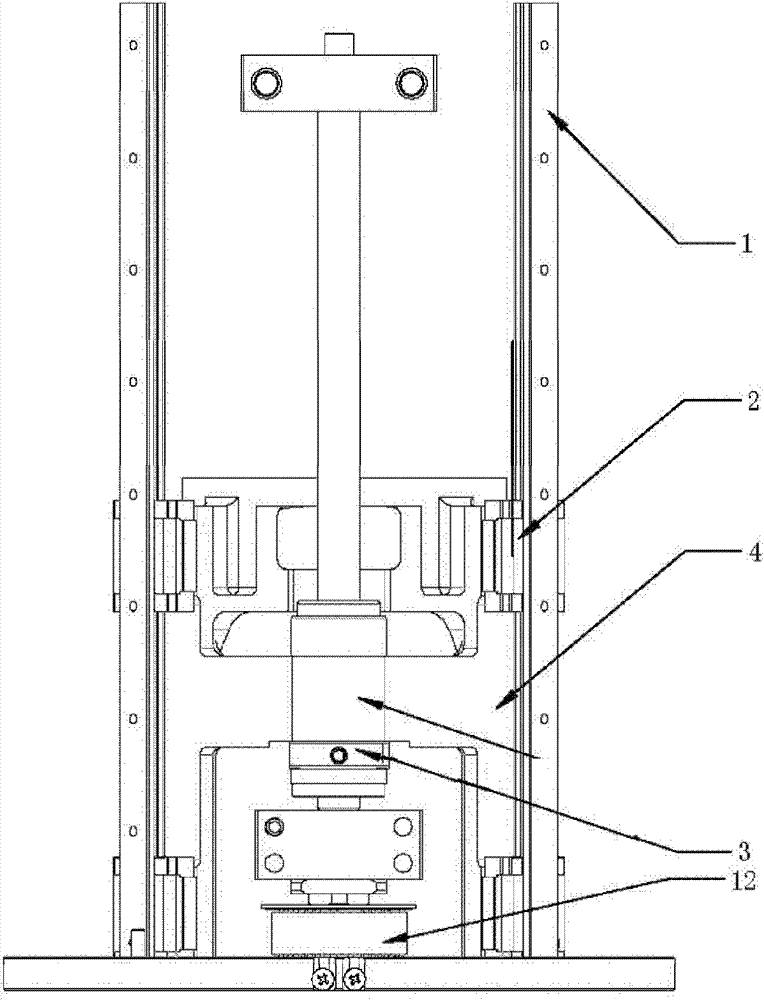

[0039] see figure 1 and figure 2 , The preferred embodiment of the column structure of the present invention is used to control the Z-axis lifting movement of the overall components inside the column, and realize the T-axis rotary motion of the arm by driving the arm assembly above the column to rotate. The preferred embodiment of the column structure includes a bottom plate 19, a vertical plate 5 installed on the bottom plate 19 as a strip, a pair of guide rails 1 installed on the bottom plate 19 and parallel to the vertical plate 5, a sliding device A slide block 2 arranged on one side of the guide rail 1, a lifting seat 4 connected to the slide block 2 that can be lifted up and down, a screw screw nut assembly 3 positioned on the plane formed by the pair of guide rails 1, an installation An electrical component 6 comprising at least one electrical appliance on one side of the guide rail 1, a pneumatic valve assembly 7 close to the electrical component 6, a Z-axis assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com