Clamping device

A clamping device and clamping technology, applied in the direction of chucks, manipulators, manufacturing tools, etc., can solve problems such as uneven force and inability to clamp wafers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

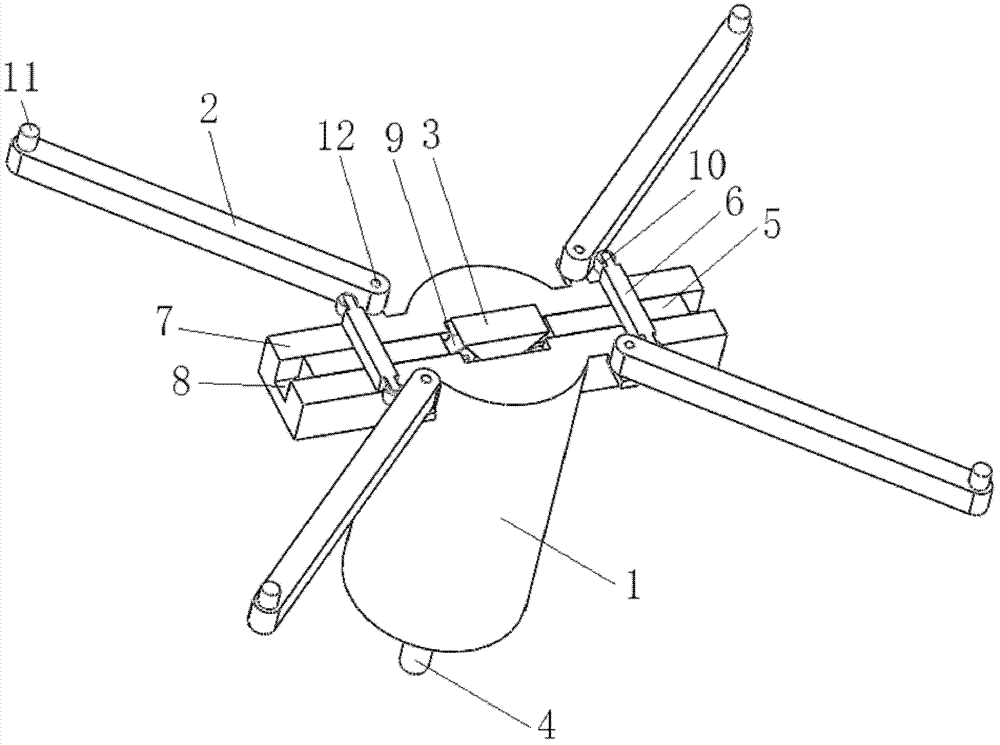

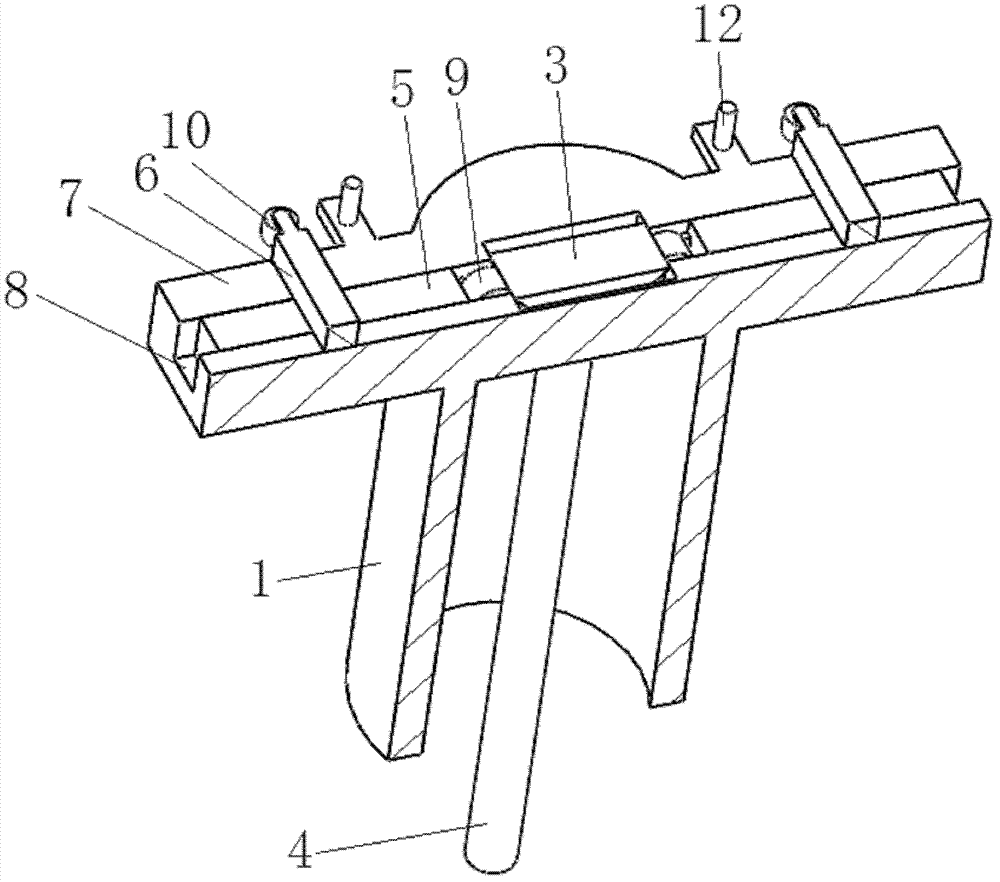

[0026] see figure 1 , in a preferred embodiment of the present invention, a clamping device includes a claw shaft 1, two sliding tables 7 arranged on the claw shaft, a contact between the two sliding tables 7 Unit 3, and the four claw arms 2 arranged on the two sliding tables 7. In one embodiment, the lengths of the four claw arms 2 are approximately equal.

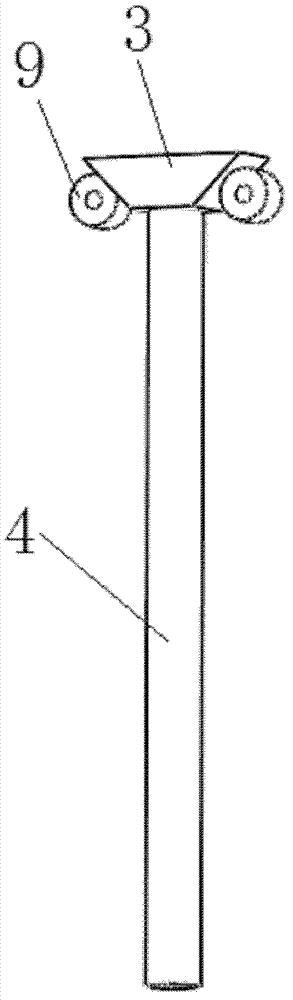

[0027] The claw shaft 1 is roughly shaped as a hollow cylinder with a centerline. One end of the jaw shaft 1 is provided with two sliding tables 7, and the other end is provided with an opening (not marked). In one embodiment, the two sliding platforms 7 are center-symmetric, and the center of symmetry is located on the center line of the jaw shaft 1 .

[0028] Please refer to figure 2 , the two slide tables 7 are provided with two chute 8 in the direction perpendicular to the centerline of the claw shaft 1, and a slide bar 5 is slidably housed in the chute 8. In one embodiment, both the sliding groove 8 and the sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com