Automatic synchronous swing device for electrophoresis production line

An automatic synchronizing and swinging device technology, applied in electrophoretic plating, electrolytic coatings, coatings, etc., can solve the problems of easy occurrence of air bubbles, hidden dangers to personal safety, and increased labor, so as to eliminate air bubbles, extend working distance and time, prevent adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

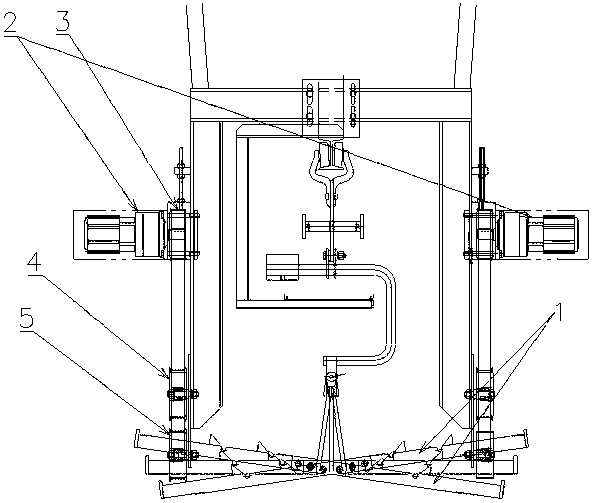

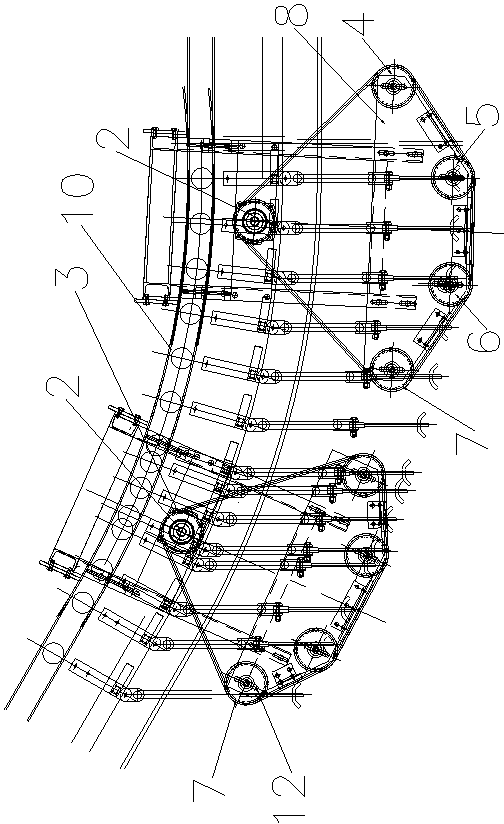

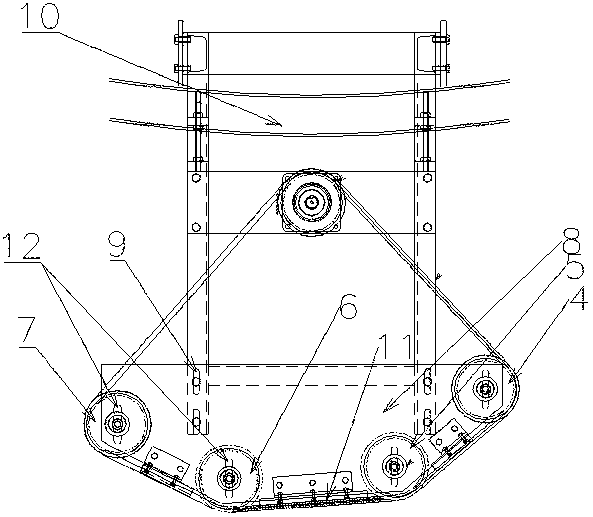

[0021] see figure 1 , figure 2 and image 3 , the automatic synchronous rocking device used in the electrophoresis production line, including two depressing devices for depressing one side of the part; the depressing device includes a frequency conversion motor 2, a driving roller 3, a first driven roller 4, a second Driven roller 5, the 3rd driven roller 6, the 4th driven roller 7 and mounting plate 8; Frequency conversion motor 2 is installed on the electrophoresis production line frame 13; A driven roller 4, a second driven roller 5, a third driven roller 6, and a fourth driven roller 7 are sequentially installed on the mounting plate 8 from left to right; the center of the first driven roller 4 and the second driven roller The connecting line between the centers of the two driven rollers 5 is the first connecting line, and the connecting line between the centers of the third driven roller 6 and the fourth driven roller 7 is the second connecting line. The first connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com