Recyclable temporary road subgrade block

A technology for temporary roads and roadbeds, which is applied to roads, roads, and paving surfaces paved with prefabricated blocks. Concrete raw material cost, cost saving measures, no pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

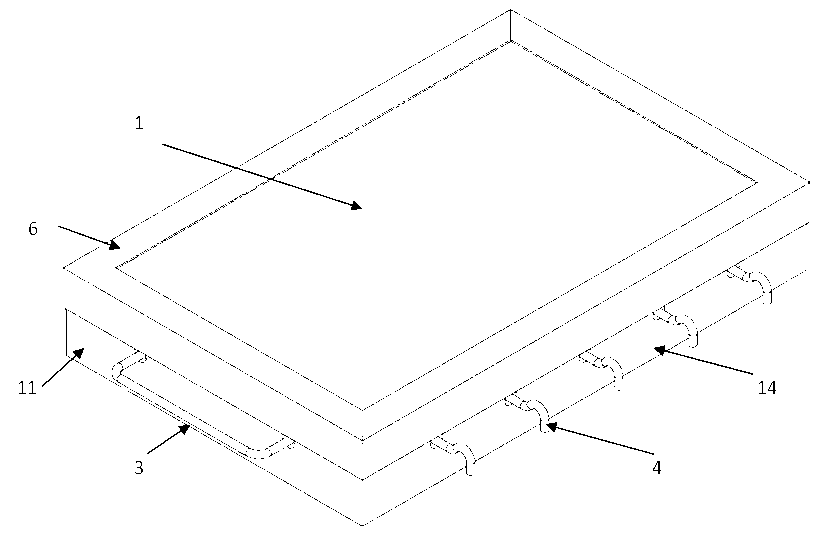

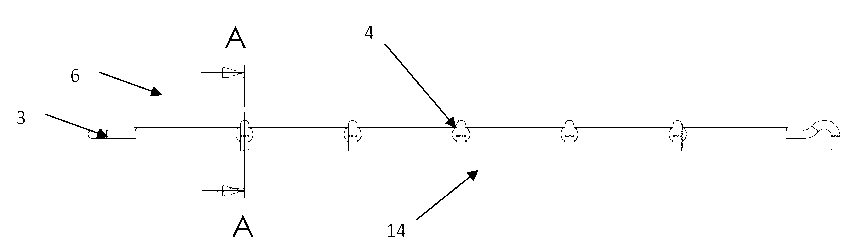

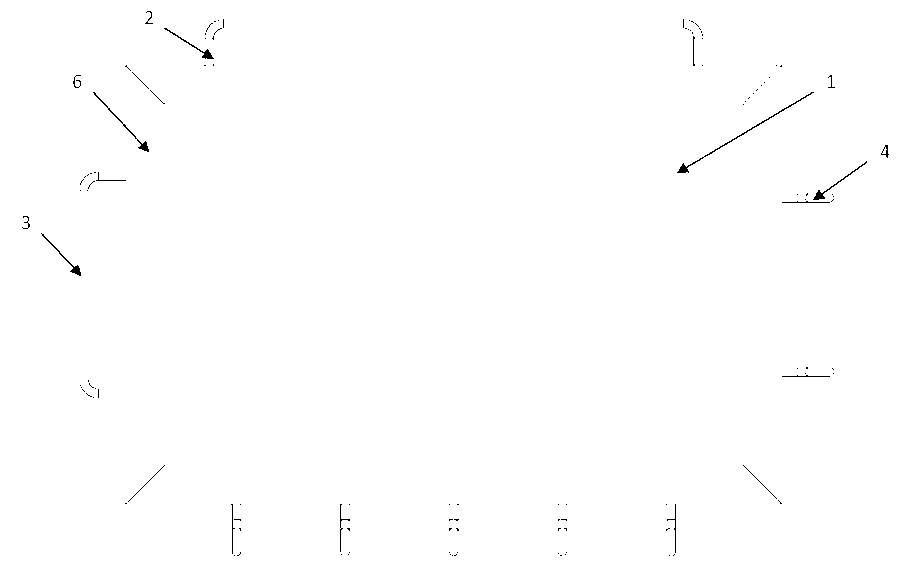

[0025] see figure 1 , a temporary road embankment block that can be turned around, consisting of a base block 1, a long-side connecting socket 2, a short-side connecting socket 3, a hook 4, a limiting block 5 and a limiting angle steel assembly 6; wherein, see image 3 , the short-side connection socket 3 is a steel bar folded into a C shape, and the two ends of the short-side connection socket 3 are fixedly connected with a limit block 5 respectively; see image 3 , the long-side connection socket 2 is a steel bar folded into a C shape, and the two ends of the long-side connection socket 2 are fixedly connected with a limit block 5 respectively; see figure 2 , the hook piece 4 is a steel bar folded into an L shape, and the end of the long rod side of the hook piece 4 is fixedly connected with a limit block 5; see Figure 5 and Image 6 , the limit block 5 is a cylinder; the diameter of the limit block 5 is greater than the diameter of the steel bars that form the long-si...

Embodiment 2

[0029] Whole structure is with embodiment 1. In addition, an edge protection angle steel assembly 8 is also provided. The edge protection angle steel assembly 8 is composed of four angle steels fixedly connected to each other. when the top of the base block 1) or set on the top of the base block 1 (when the limit angle steel assembly 6 is hooped on the bottom of the base block 1), see Figure 7 . That is, the limit block 5 connecting the hook piece 4, the long-side connection socket 2 and the short-side connection socket 3 through the limit angle steel assembly 6 is restricted to expand and contract in the corresponding blind hole 7, and is protected by the edge protection angle steel assembly 8. The edge of substrate 1, such as Figure 8 shown.

Embodiment 3

[0031] Whole structure is with embodiment 1. In addition, an edge protection angle steel assembly 8 is also provided. The edge protection angle steel assembly 8 is composed of four angle steels fixedly connected to each other. when the top of the base block 1) or set on the top of the base block 1 (when the limit angle steel assembly 6 is hooped on the bottom of the base block 1), see Figure 9 . Wherein, the height H3 of the vertical edge of the edge protection angle steel assembly 8 is greater than the shortest distance H4 from the horizontal edge of the edge protection angle steel assembly 8 to the edge of the blind hole 7, as shown in Figure 19; that is, through the limit angle steel assembly 6 and the edge protection angle steel assembly 8 each of the four vertical sides half-closes the opening end of each blind hole 7 on the base body 1, so that the stopper 5 connected to the hook 4, the long-side connection socket 2 or the short-side connection socket 3 is closed. Limit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com