Light composite structure jacket type offshore platform

A combined structure and offshore platform technology, applied in underwater structures, infrastructure engineering, construction, etc., can solve the problems of component loss of bearing capacity, vibration comfort, durability, impact resistance and fire resistance, and overall structural damage and other problems, to achieve the effect of large overall bearing capacity and stiffness, good impact resistance, and improved local buckling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

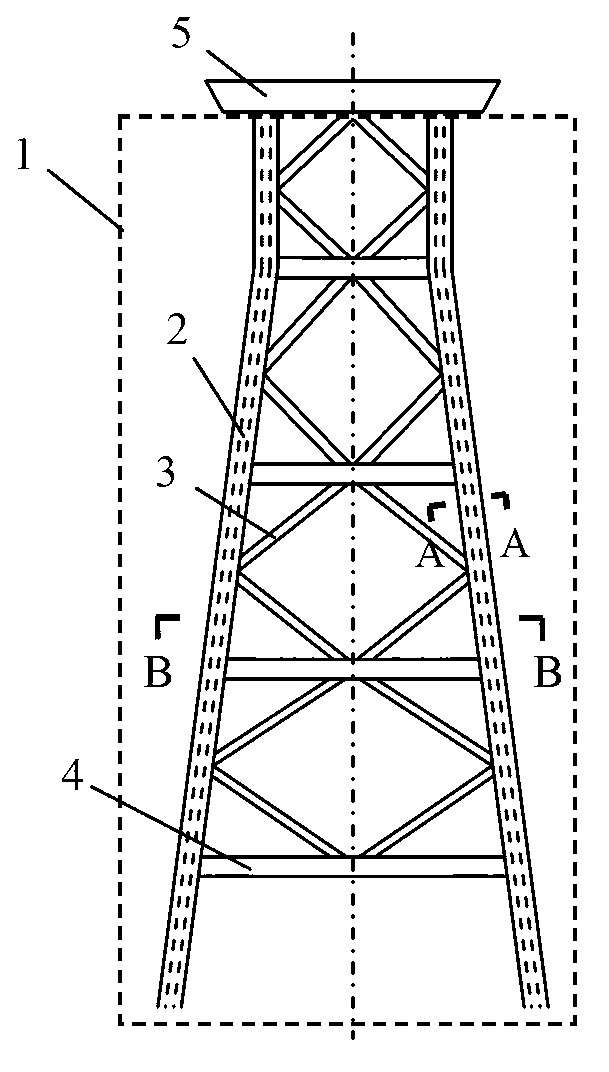

[0027] The present invention provides a jacket-type offshore platform structure with a light composite structure. The structure and specific implementation methods of the present invention will be further described below in conjunction with the embodiments and accompanying drawings.

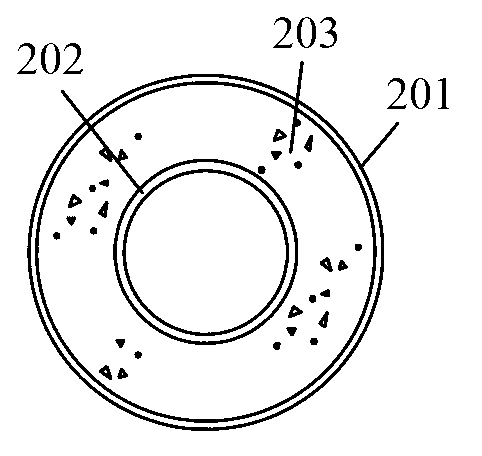

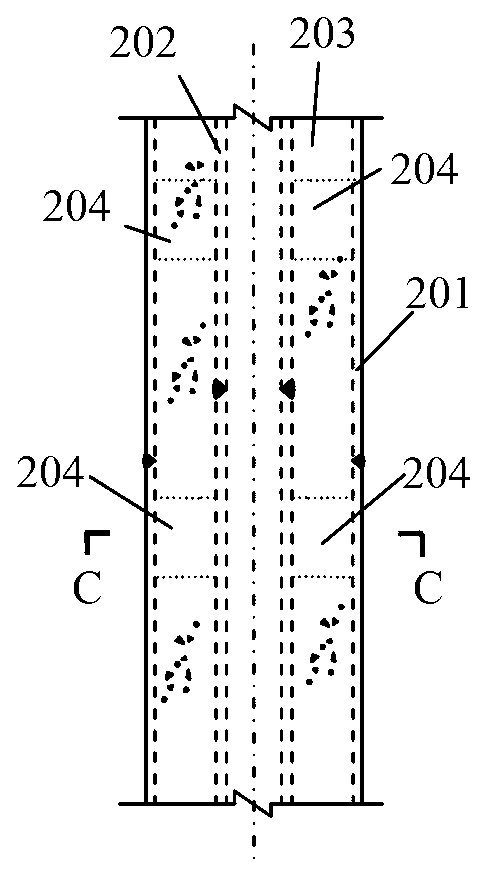

[0028] figure 1 It is a schematic diagram of the platform structure of the embodiment of the present invention, and the platform structure is composed of a platform frame 1 of a light composite structure and a platform 5 welded thereto, wherein the platform frame 1 is composed of a 4-leg platform main pole 2, a platform brace 3 and a platform cross Support 4 forms. The main rod 2 of the platform is composed of light steel-concrete composite members connected by welding along the length direction. The specific structure is: the inner steel pipe 202 is placed in the outer steel pipe 201 and is coaxial with the outer steel pipe 201, and the space between the outer steel pipe 201 and the inner steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com