Cushioning and vibration damping device for support of intelligent well

A technology of vibration damping device and intelligent well, which is applied to pillars/supports, mining equipment, earth-moving drilling, etc., and can solve the problem of the increase in the deflection of the roof, the increase in the compression step distance and the caving height, and the theoretical imbalance between the support and surrounding rock. and other problems, to achieve the effect of preventing the increase of step distance and slump height, preventing the increase of flexural deformation, and optimizing the effect of buffering and vibration reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

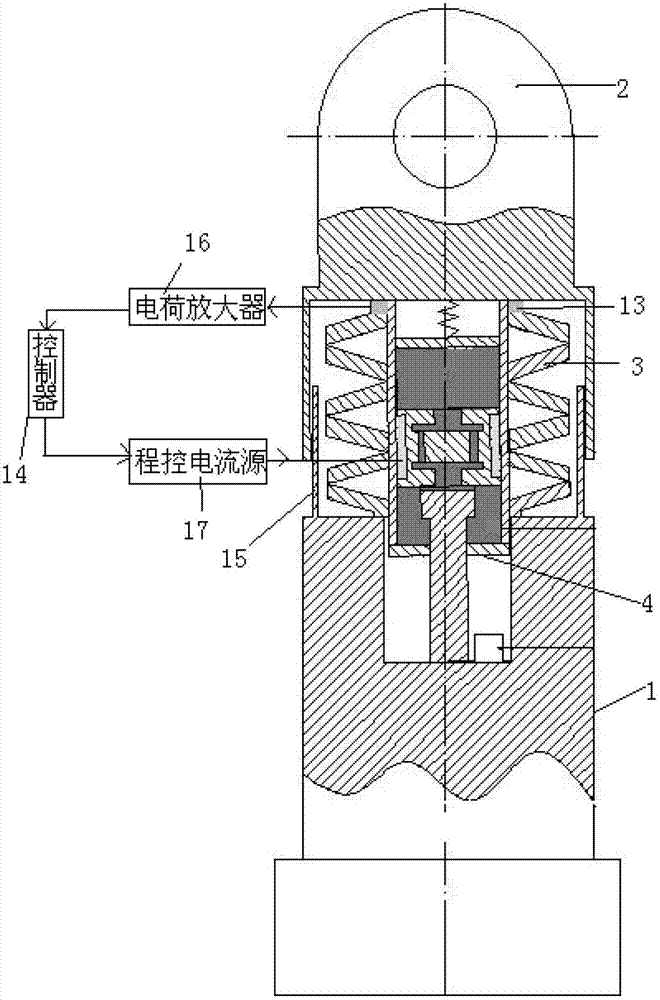

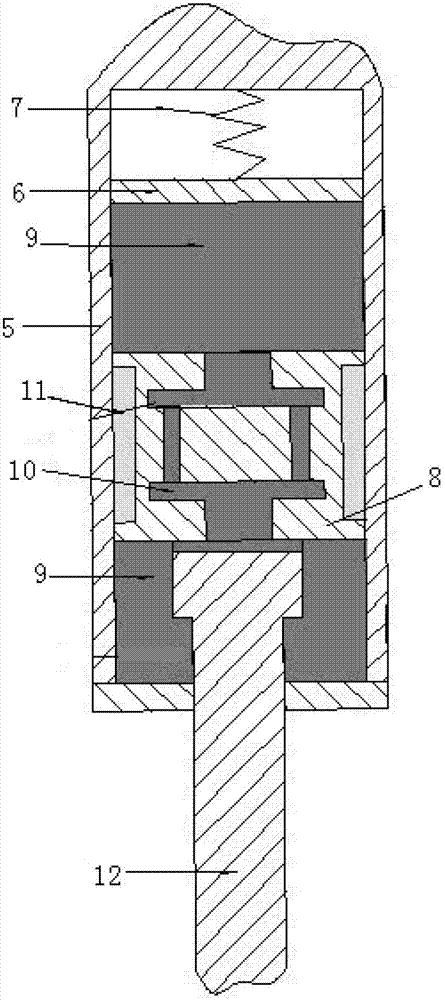

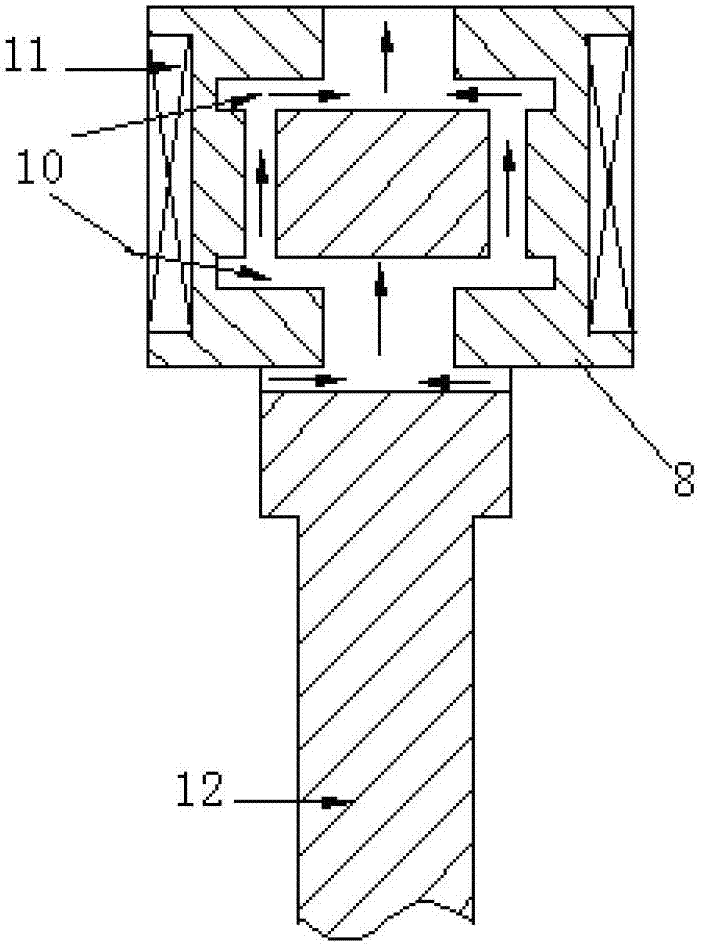

[0015] Such as figure 1 , 2 3. As shown in 3, a support cushioning and damping device for smart wells includes a cylinder 1, a cylinder head 2, a disc spring group 3, and a magnetorheological damping device 4. The magnetorheological damping device 4 includes a cylinder Tube 5, the top of the cylinder tube 5 is connected with the column head 2 as a whole, a floating piston 6 is provided inside the cylinder tube 5, a spring 7 is fixed between the floating piston 6 and the column head 2, inside the cylinder tube 5 The lower part of the floating piston 6 is provided with a piston 8 and filled with magnetorheological fluid 9. A channel 10 is opened inside the piston 8, a coil 11 is wound on the outside of the piston 8, and a piston rod 12 is connected below the piston 8. 12 penetrates the bottom of the cylinder tube 5 and is fixed on the cylinder 1, the disc spring group 3 is installed on the outer surface of the cylinder tube 5 through its inner hole, and the disc spring group 3 Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com