Organic Rankine cycle waste heat recovery power generation system with separation and expansion device

An expansion device and waste heat recovery technology, which is applied in steam engine devices, machines/engines, mechanical equipment, etc., to reduce exhaust temperature, increase average heat absorption temperature, and improve heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

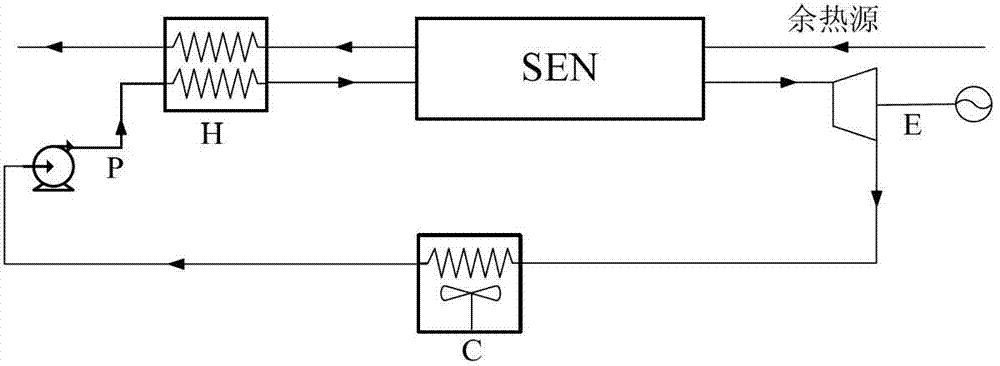

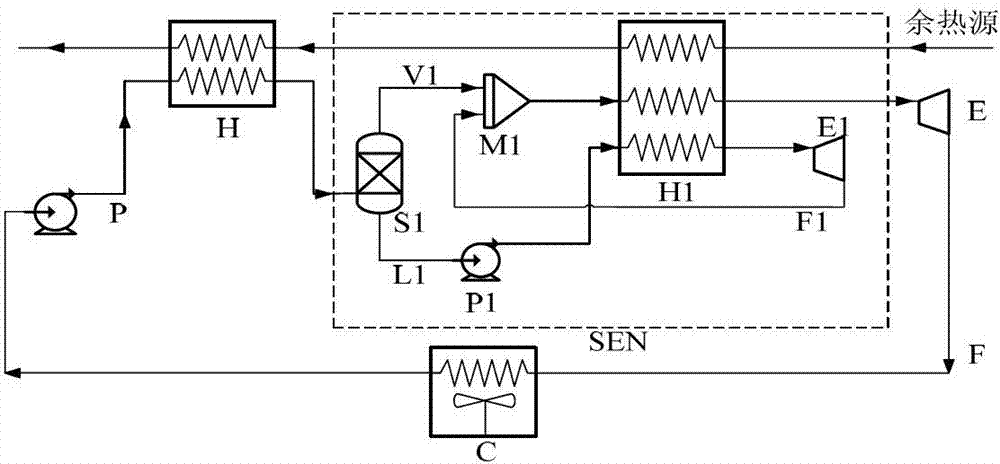

[0034] refer to figure 1 and figure 2 , this embodiment is an organic Rankine cycle waste heat recovery power generation system with a first-stage separation expansion device, which is suitable for a waste heat source with a temperature of 150°C. Here, it is assumed that the flow rate of the waste heat source is 1kg / s; the organic working medium of the system is R245fa; the organic working medium fluid with a flow rate of 0.322kg / s is condensed to a saturated liquid at 30°C through the condenser C (the corresponding saturation pressure is 0.177MPa), pressurized to 0.758MPa by the total working medium booster pump P, and then passed through The preheater H is preheated to a two-phase state where the molar composition of the gas phase accounts for 0.31, and then separated into two streams of the primary gas phase flow V1 and the primary liquid phase flow L1 by the primary vapor-liquid separator S1; the primary liquid phase flow L1 is pressurized to 1.78MPa by the first-stage w...

Embodiment 2

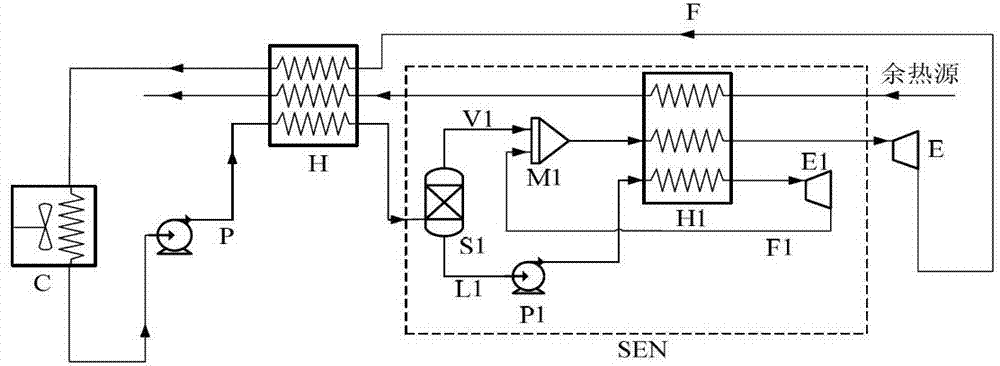

[0036] refer to image 3 , the organic Rankine cycle waste heat recovery power generation system with a one-stage separation expansion device in this embodiment: the exhaust steam discharged from the low-temperature expander E enters the preheater H again to release heat to the organic working medium, and then condenses into a liquid through the condenser C ; The other parts of the system and the system cycle parameters are the same as in Example 1; the system is suitable for a waste heat source with a temperature of 150°C, assuming that the flow rate of the waste heat source is 1kg / s; the net output power of the system is 10.16kW, and the thermal efficiency is 13.77% .

Embodiment 3

[0038] refer to Figure 4 , this embodiment is an organic Rankine cycle waste heat recovery power generation system with a two-stage separation expansion device, which is suitable for a waste heat source with a temperature of 200°C. Here, it is assumed that the flow rate of the waste heat source is 1kg / s. The organic working fluid of the system is acetone; the organic working fluid with a flow rate of 0.1564kg / s is condensed to a saturated liquid at 30°C through the condenser C (the corresponding saturation pressure is 0.0365MPa), and pressurized by the total working fluid The pump P is pressurized to 0.4MPa, and then preheated by the preheater H to a two-phase state where the molar composition of the gas phase accounts for 0.3, and then separated into a primary gas phase flow V1 and a primary liquid phase flow L1 by the primary vapor-liquid separator S1 Two fluids; the primary liquid phase flow L1 is pressurized to 0.75MPa by the primary working fluid booster pump P1, heated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com