Hydraulic buffer system for rotary dampers

A technology of rotary damper and hydraulic buffer, applied in the direction of shock absorber, shock absorber, liquid shock absorber, etc., can solve the problem of oil leakage of hydraulic components and pipeline joints, unbalanced force on hydraulic cylinders, and inability of vehicles to run, etc. problems, to achieve the effect of improving competitiveness, simple pressure control, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention.

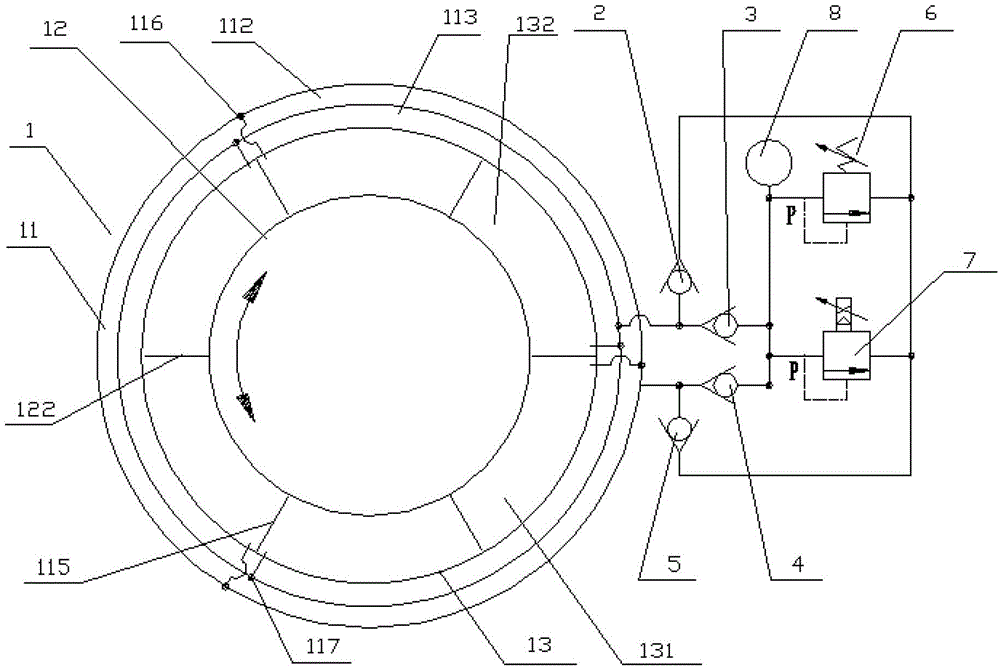

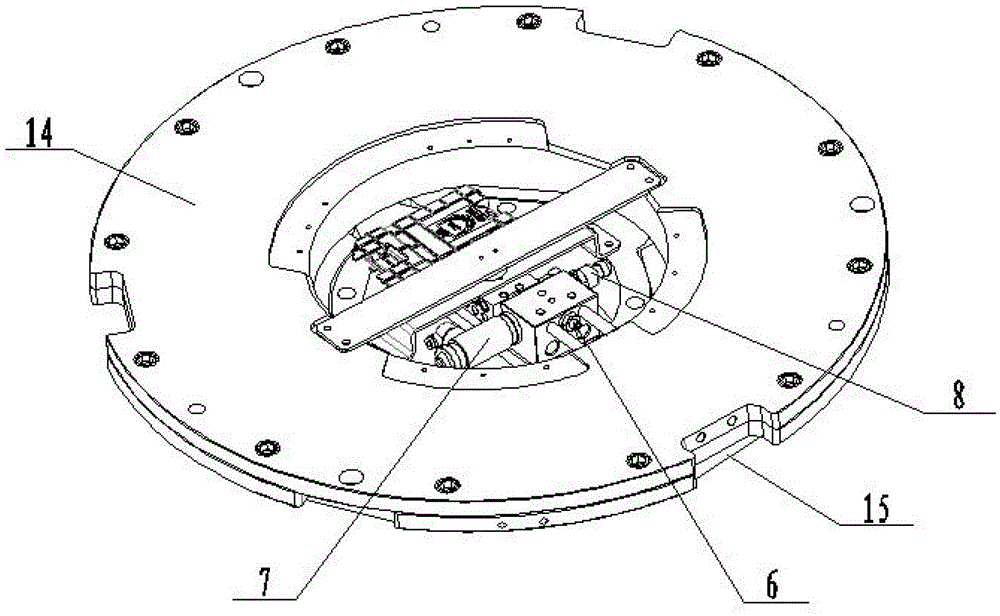

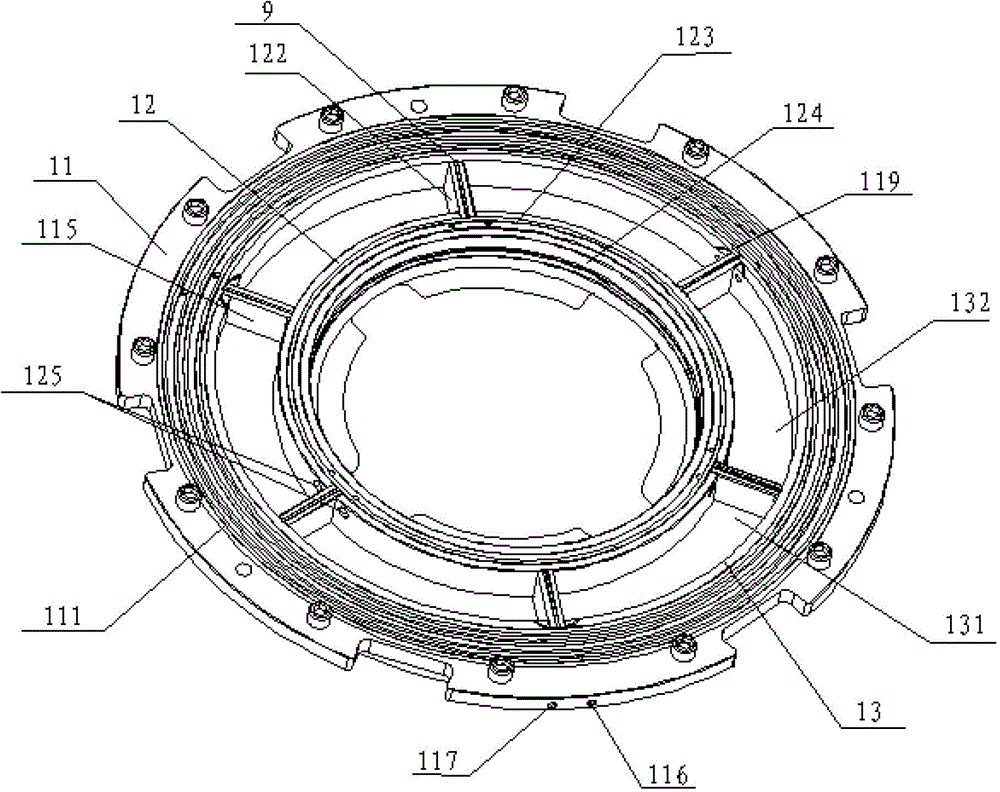

[0029] Such as figure 1 As shown, the rotary damper hydraulic buffer system disclosed in the present invention includes a rotary damper 1, a first one-way valve 2, a second one-way valve 3, a third one-way valve 4, a fourth one-way valve 5, an overflow A flow valve 6, a proportional relief valve 7 and a pressure sensor 8, the rotary damper 1 includes a stator 11, a rotor 12 rotating relative to the stator, and a hydraulic chamber 13 formed between the stator 11 and the rotor 12, the rotor 12 is located inside the stator 11, And concentrically arranged, the first oil passage 112 and the second oil passage 113 are arranged on the circumferential direction of the flange surface 111 of the upper end of the stator 11 . The hydraulic chamber 13 includes at least one first chamber 131 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com