Method and system for judging reliability of man-machine interface of digital control system through human factor reliability

A technology of man-machine interface and control system, which is applied in the field of digital control of power plants and nuclear power plants, and can solve problems such as inability to respond to the impact of personnel behavior

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

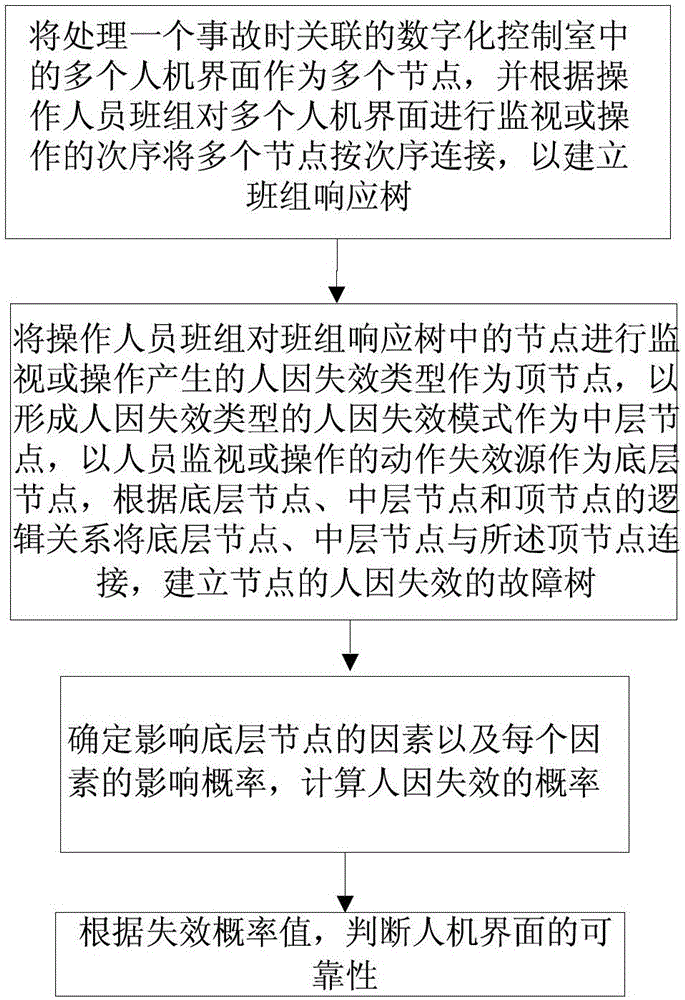

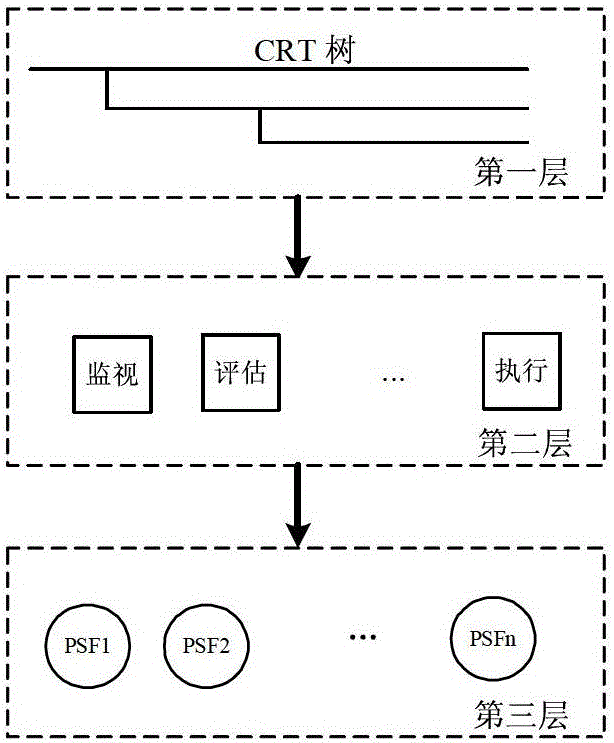

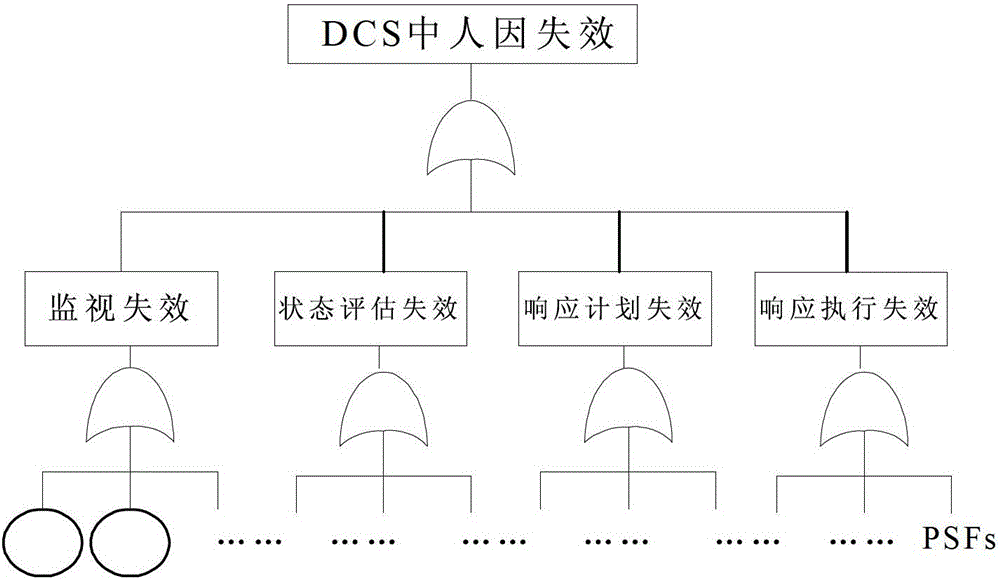

Method used

Image

Examples

Embodiment 1

[0061] This embodiment takes the steam generator tube rupture (SGTR, steam generator tube rupture) accident in the DCS of a certain nuclear power plant as an example to specifically illustrate the method and system for judging the reliability of the DCS man-machine interface through the HRA of the present invention. The method includes the steps of:

[0062] Step S001: Define human accidents. SGTR is a human-caused accident with a high frequency of originating accidents. After the SGTR accident, it can quickly cause the secondary circuit radioactivity (N16) high alarm and other alarm signals, including the abnormality of the damaged SG liquid level and the low pressure alarm of the voltage regulator. In DCS, about 3 minutes after SGTR appears, alarm signals appear. These alarms include: low pressure and low liquid level of voltage regulator, rise of damaged SG liquid level, inconsistency of water supply between intact SG and damaged SG, secondary circuit radioactive alarm, et...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com