Novel composite flame-retardant cable

A fire-resistant cable, a new technology, applied in the field of power cables, can solve the problems of increased processing cost and raw material cost, poor processing performance, and extrusion wall thickness cannot be thin enough, so as to reduce personal casualties and property losses, and avoid processing performance , the effect of diameter increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

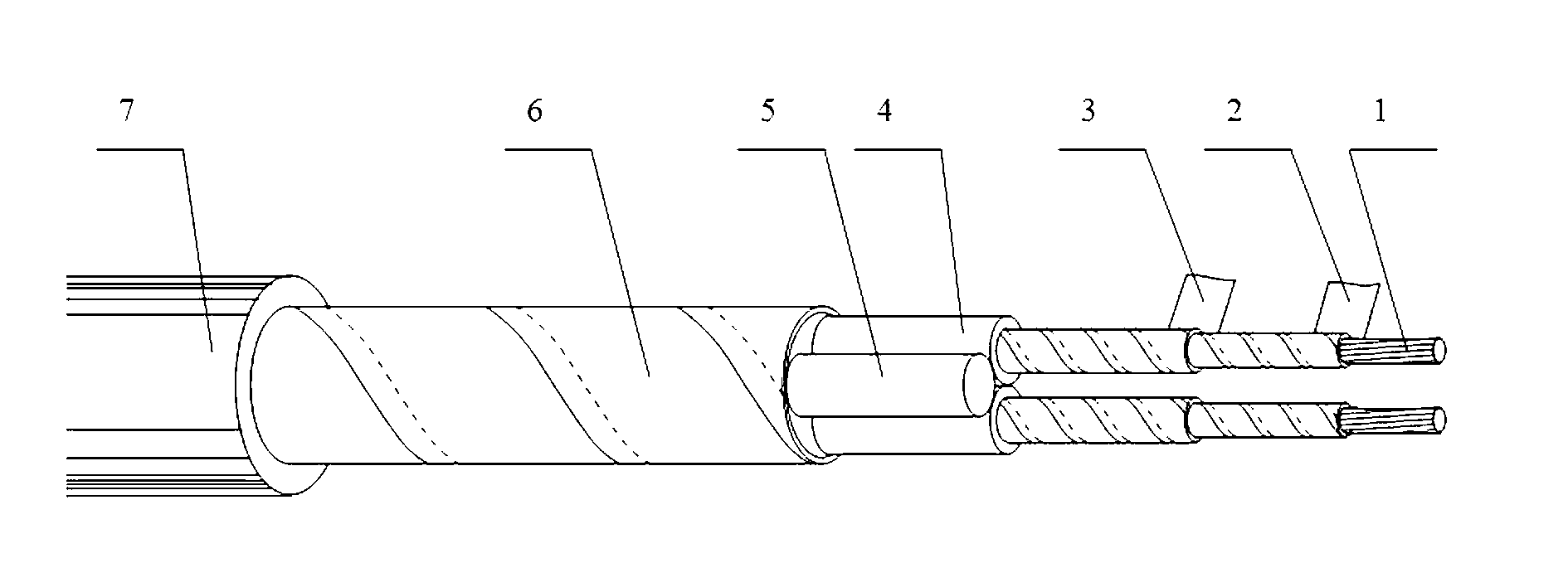

[0014] See figure 1 . The conductor 1 is wrapped with a mica tape 2 , and the mica tape 2 is wrapped with a ceramic silicon rubber composite tape 3 . Ceramic silicone rubber composite tape 3 and mica tape 2 are wound in the same direction. Insulate the sheath 4 outside the wrapped vitrified silicone rubber composite tape 3 .

[0015] In the above process, the overlapping amount of the mica tape is 35% of the width of the mica tape, and the overlapping amount of the ceramic silicone rubber composite tape is 15% of the width of the ceramic silicone rubber composite tape. The thickness of the ceramized silicone rubber composite tape used was 0.14 mm.

[0016] Wrap the two conductor cores and a filling core 5 with a flame-retardant tape 6 after the above-mentioned process, and finally extrude the outer sheath 7, which is a form of the new composite fire-resistant cable of the present invention. Here, the filling core 5, the flame-retardant tape 6 and the outer sheath 7 are all...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com