Contactor

A contactor and contact part technology, which is applied to contact parts, antenna connectors, connections, etc., can solve the problems of connecting the contact part 16 and the elastic part 13 of the seat plate 10 deformation, operator injury, and reduced work efficiency, etc. Effectiveness of work efficiency, workability improvement, and stable connection status

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

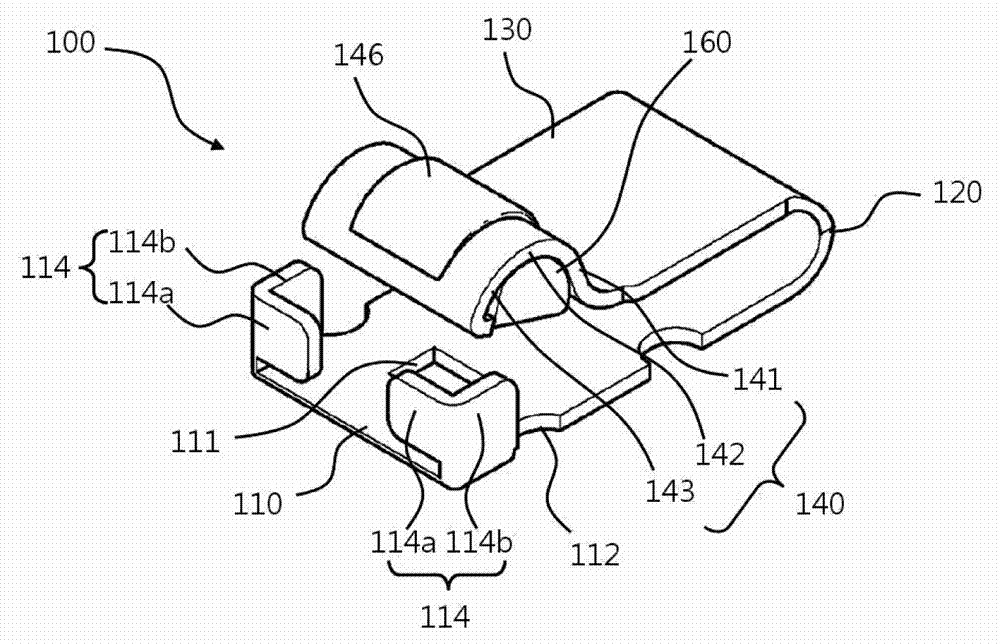

[0049] Hereinafter, a contactor according to an embodiment of the present invention will be described in detail with reference to the accompanying drawings.

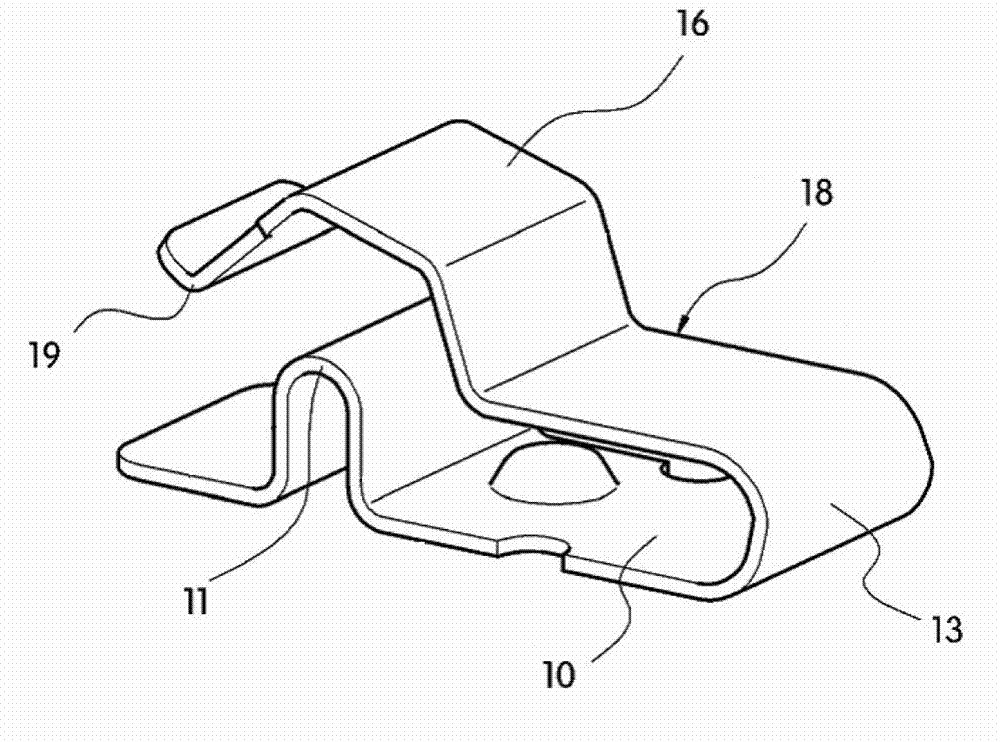

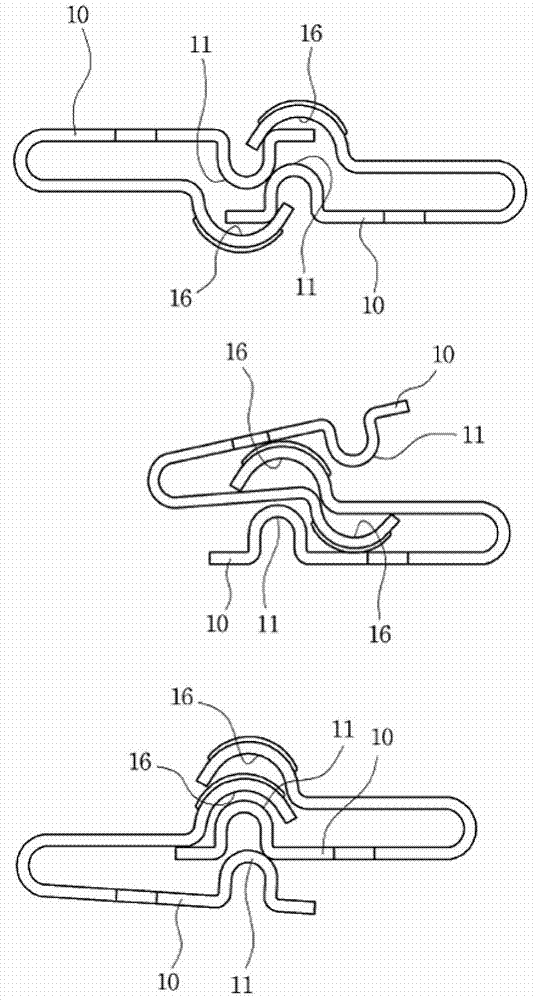

[0050] first, Figure 3a and Figure 3b are respectively a perspective view and a bottom perspective view showing a contactor according to an embodiment of the present invention, Figure 4 is a side view showing a contactor according to an embodiment of the present invention.

[0051] As shown in the figure, a contactor 100 according to an embodiment of the present invention has a seat plate 110 which is fixed to a substrate or the like and functions as a fixed end, and is located on an upper portion of the seat plate 110 and includes a contact portion for contacting a terminal. The free end of 140 and the elastic part 120 connecting the fixed end and the free end form an integrated structure.

[0052] The elastic portion 120 extends from one end of the seat plate 110 and is curved upward in a circular shape, and acts a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com