Water adding and dispersing regulating method for smoked sheet damping machine of high-inertia system

An adjustment method and inertial system technology, which are applied in the field of discrete adjustment of water addition of tobacco reconditioning machines, which can solve the problems of continuous oscillation, many interference factors, and unstable outlet moisture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

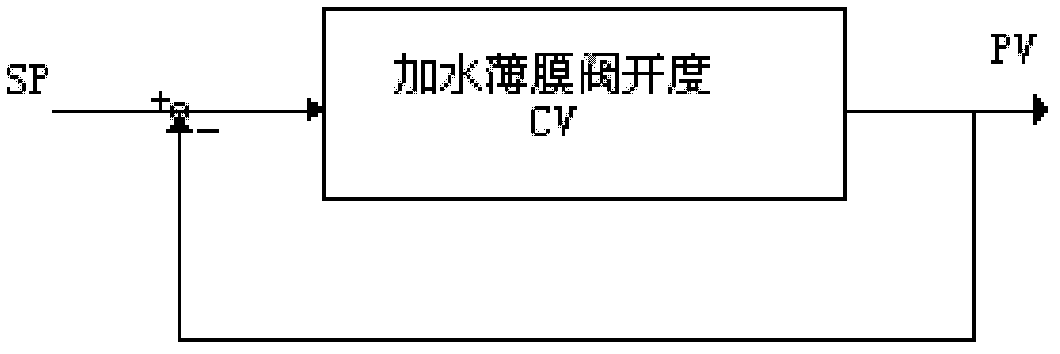

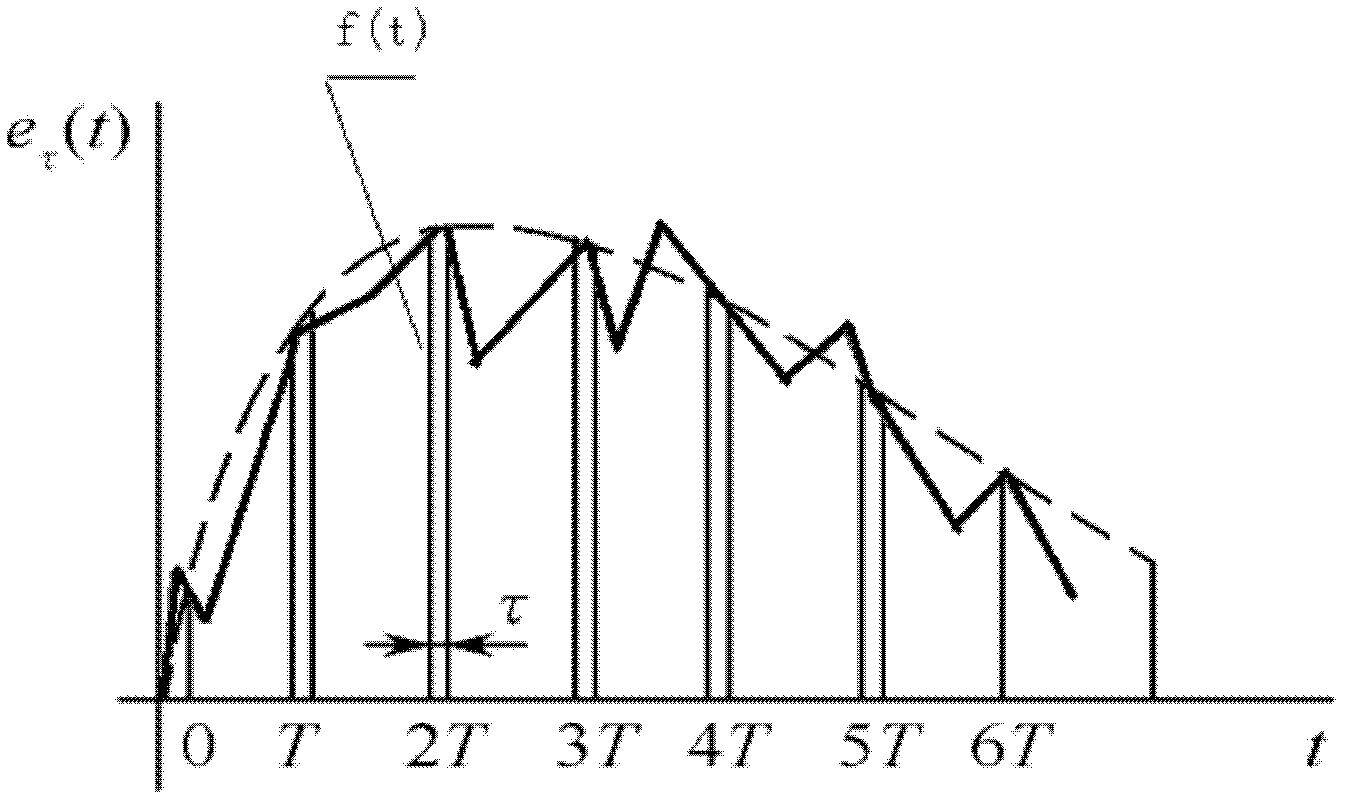

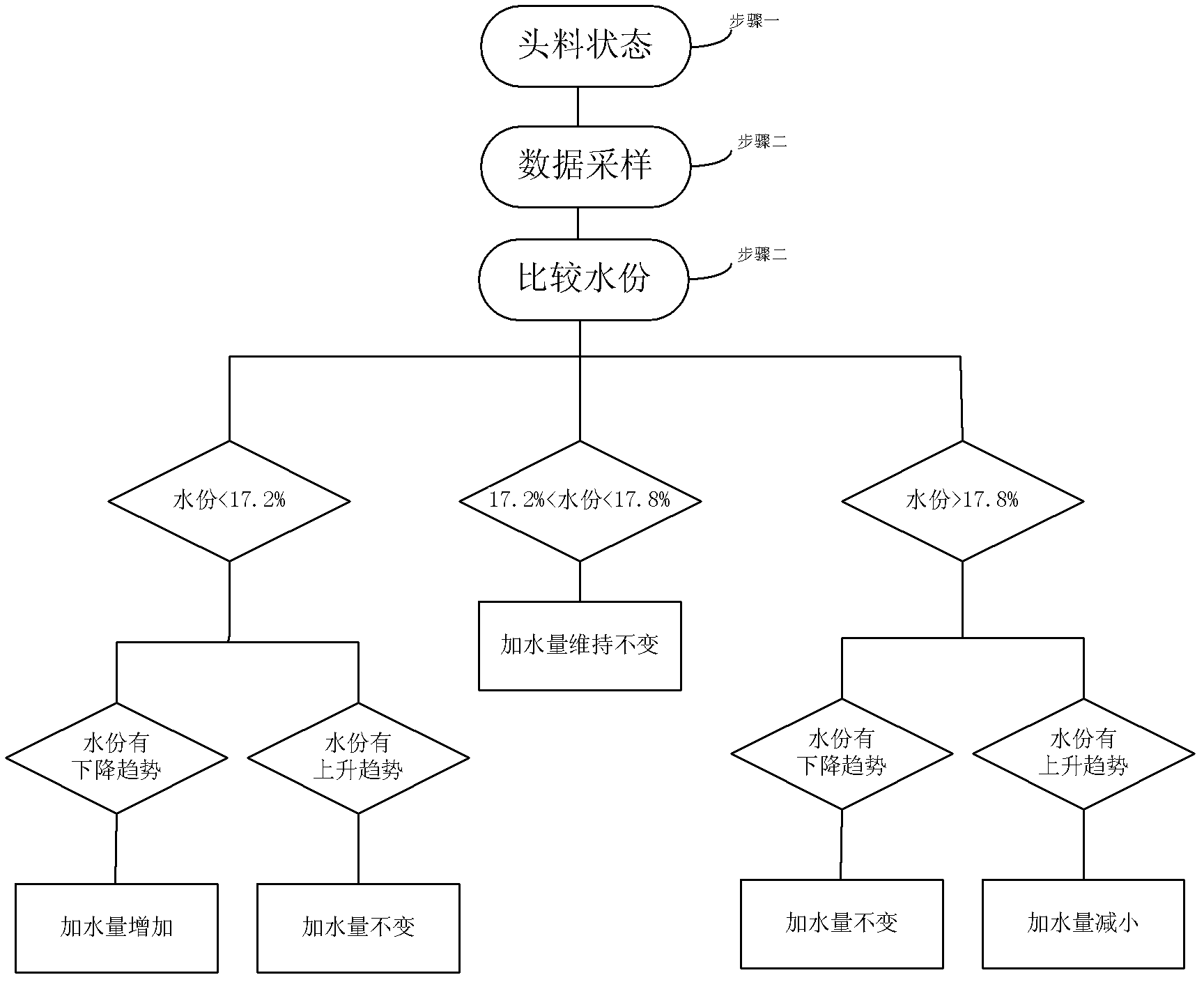

[0024] combined control flow image 3 and system box Figure 4 The present invention is described in detail as follows.

[0025] Step 1 is divided into two stages:

[0026] Stage 1. The system estimates the function based on water addition: water addition setting value (kg / h) = inlet material flow rate 2400 (kg / h) × (moisture content setting value 17.5-constant 12) / (constant 100-moisture content setting value 17.5) × water addition coefficient 0.3 to calculate the amount of water added, and control the water addition to the tobacco leaves in the head state;

[0027] Stage 2: PLC programmable controller 1 detects whether there is any material 3. Tobacco leaves are output from the sheet reconditioning cylinder to determine whether the state of the top material is over. If not, continue to step 1. When there are tobacco leaves output from the tobacco sheet reconditioning cylinder, it is the top material When the state is nearing the end, the system continues to adjust the wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com