Punch feeding machine capable of discharging materials with machine visual guidance

A machine vision and discharging technology, which is applied to metal processing equipment, feeding devices, manufacturing tools, etc., can solve the problems of inability to load sheets, inability to continuously load and discharge, and reduce the efficiency of manual operation, so as to improve the efficiency of manual operation. Stamping efficiency and production cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

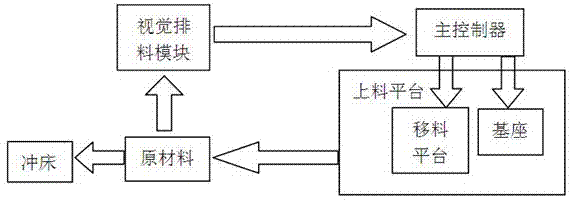

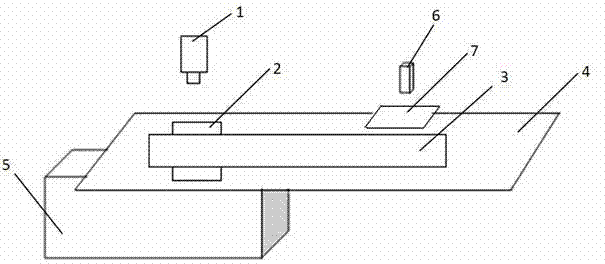

[0014] Such as Figure 1-2 As shown, the punching machine for machine vision-guided discharge described in the embodiment of the present invention uses the intelligent machine vision device 1 and light source 2 of the visual discharge module to independently extract the shape contour of the raw material 3 and optimize the discharge according to the contour change at any time. Calculate and output punching position. The main controller controls the material-moving platform 4 and the base 5 of the loading platform according to all the punching positions to realize the material-moving action, and controls the punch 6 of the punching machine to realize the continuous punching action. The material transfer platform 4 is installed on the base 5 .

[0015] The invention makes full use of machine vision to guide the nesting, which can not only optimize the nesting according to the contour change at any time, but also continuously punch the material to improve work efficiency. Space ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com