Hydraulic bench clamp and workpiece clamping method using same

A vise and hydraulic technology, applied in metal processing machinery parts, clamping, positioning devices, etc., can solve the problem of not being able to meet the batch processing requirements of various small precision workpieces, reduce the clamping time, and achieve uniform clamping force. , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

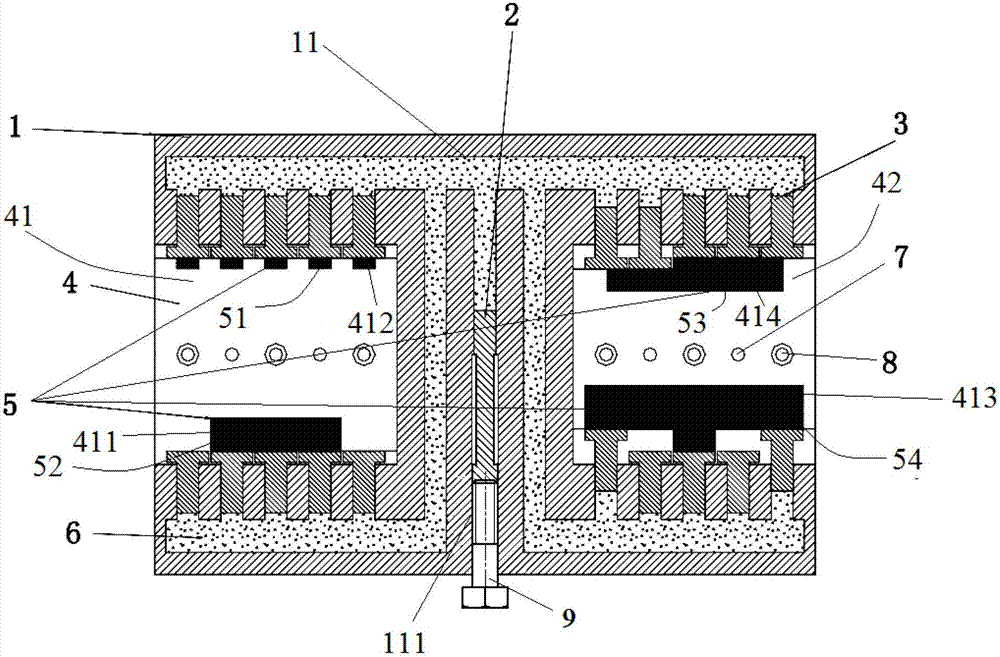

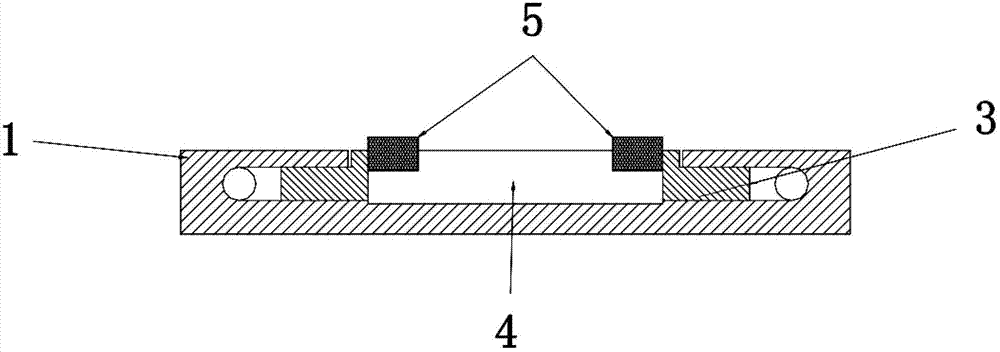

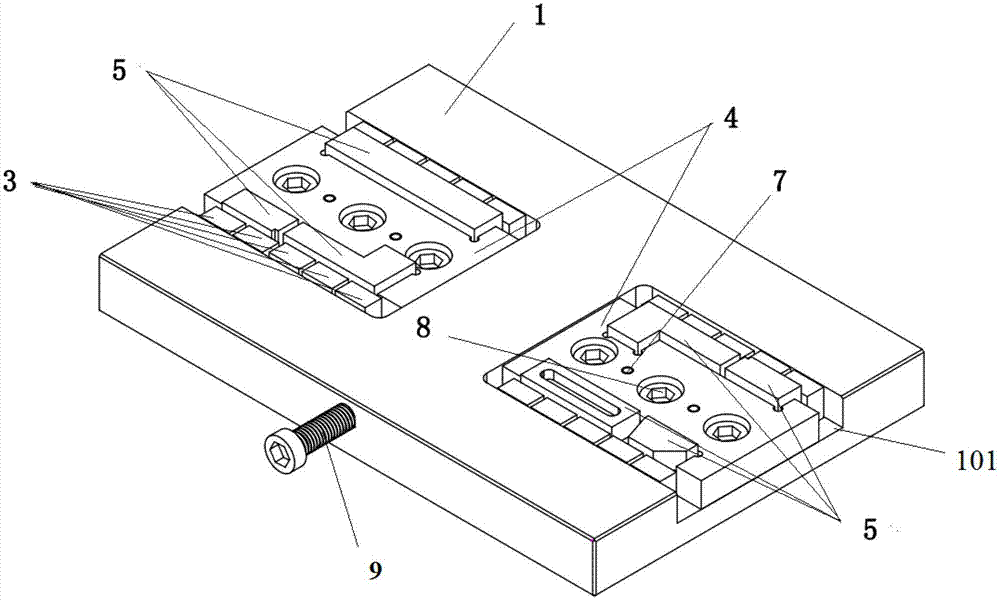

[0023] figure 1 , figure 2 and image 3 It shows a hydraulic vise provided by a preferred embodiment of the present invention, including a vise main body 1, a reciprocating push piston 2 placed inside the vise main body 1, a plurality of The reciprocating driven piston 3 on 1 and the fixed jaw 4 fixed on the main body 1 of the vise; the main body 1 of the vise is provided with a hydraulic pipeline 11 for filling hydraulic oil 6, the The push piston 2 is installed and can reciprocate in the hydraulic pipeline 11 . The hydraulic pipeline 11 is also provided with a plurality of openings outside the vise main body 1, and the plurality of driven pistons 3 are respectively installed at the plurality of openings and can reciprocate in the plurality of openings respectively, serving as The clamping head is used to clamp the workpiece 5 to be processed, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com