Composite floor adhesive force testing device

A testing device and composite floor technology, applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve the problems of complicated operation, large volume, complicated structure, etc., and achieve the effects of convenient and fast operation, overcoming large volume, and reducing manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

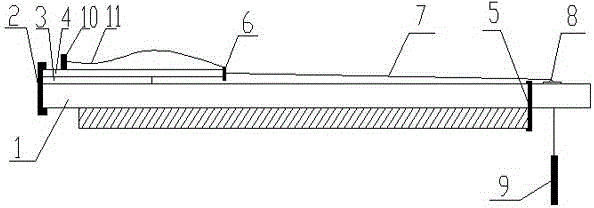

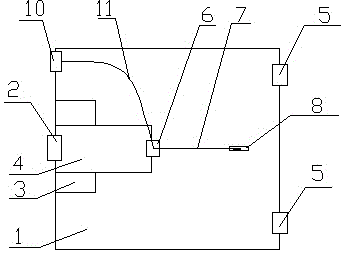

[0015] like figure 1 As shown, the present embodiment provides a composite floor adhesion testing device, including a base plate 1, a fixing seat 2, and a pull-down device. It is fixed together with the base plate 3, the pull-down device is arranged on the right side of the base plate 1, the base plate 1 is provided with a base plate 3 and a test object 4, the test object 4 is located above the base plate 1, and the base plate 3 is located between the base plate 1 and the test object 4. The middle of the test object 4 is used to eliminate the friction between the test object and the bottom plate during the test. The right side of the base plate 1 is provided with a fixing clip 5 for fixing the base plate on the desktop, and the stretching device includes a clamping member 6, a traction belt 7, a pulley 8 and a tension gauge 9, and the lower part of the right side of the base plate 1 is There is a through hole, the pulley 8 is fixed on the through hole of the bottom plate 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com