Flue gas desulfurization system

A desulfurization system and flue gas technology, applied in the field of air pollution control, can solve the problems of difficulty in meeting the requirements of desulfurization efficiency, insufficient gas-liquid reaction, and long oxidation and crystallization time, so as to improve the oxidation rate and desulfurization efficiency of the system, save space, The effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to clarify the technical scheme and technical purpose of the present invention, the present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

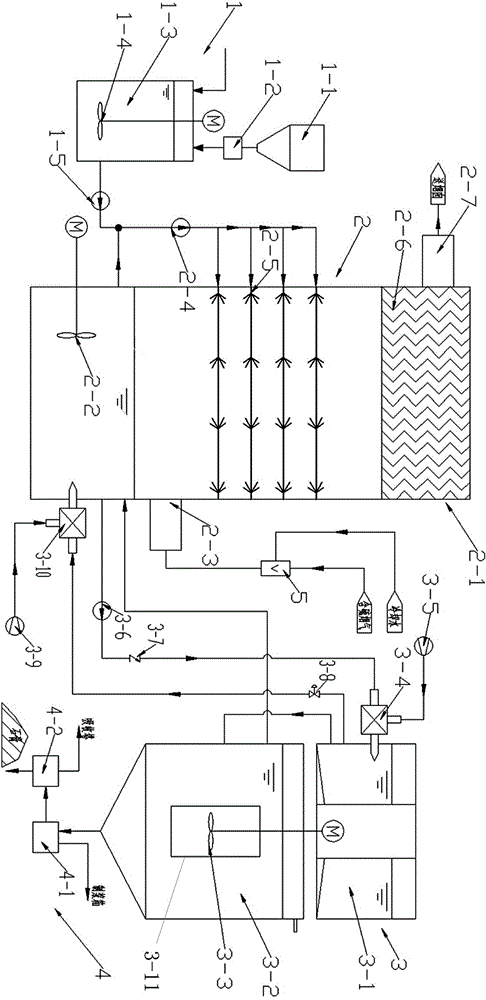

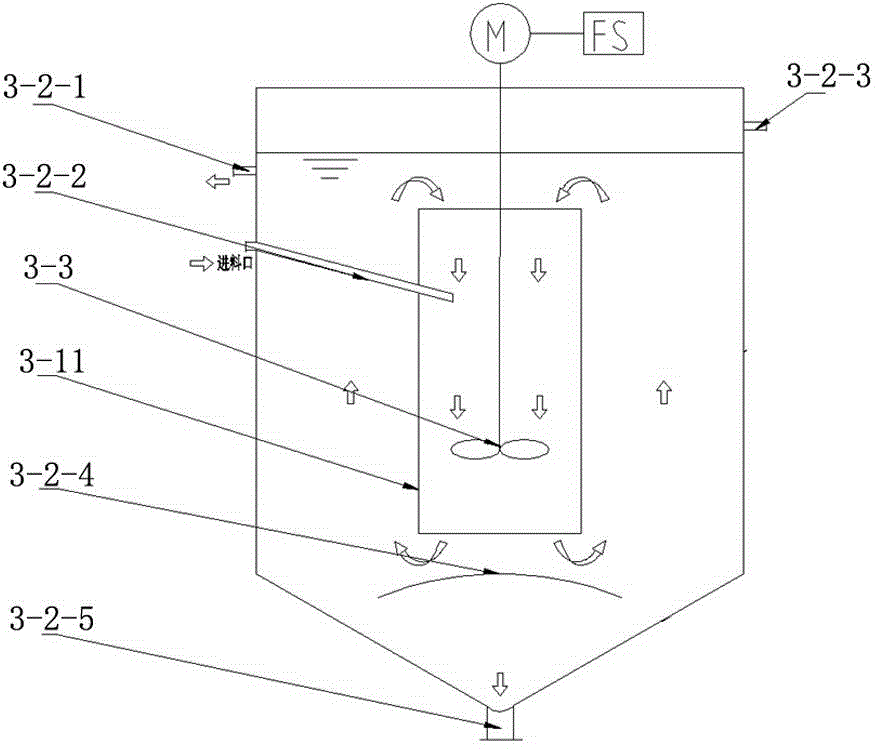

[0032] Such as figure 1 A flue gas desulfurization system shown includes the following components:

[0033] (1) Raw material system 1;

[0034] The raw material system 1 includes a desulfurizing agent powder bin 1-1, a screw feeder 1-2, a pulping box 1-3, an agitator 1-4, a slurry supply pump 1-5, etc. The desulfurizing agent in this embodiment adopts granular Limestone powder with a diameter of 200-300 mesh and a purity greater than 90% is directly beaten to the powder bin 1-1 by a pump truck, weighed by the feeder 1-2, and then transported to the pulping box 1-3, and mixed with the hydraulic cyclone. The overflow liquid of the flow device 4-1 or the process water are mixed to form a desulfurization slurry, the slurry has a solid content of 10% to 15%, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com