Balance mechanism of drilling and milling head of gantry movable type numerical-control drilling and milling machine

A mobile, drilling and milling machine technology, applied in the direction of metal processing machinery parts, other manufacturing equipment/tools, maintenance and safety accessories, etc., can solve the problems of increasing the power of the lifting spindle, the difficulty of replacing the wire rope, and the breakage of the wire rope, so as to reduce the driving force. force, ensure the stability and the effect of cutting machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

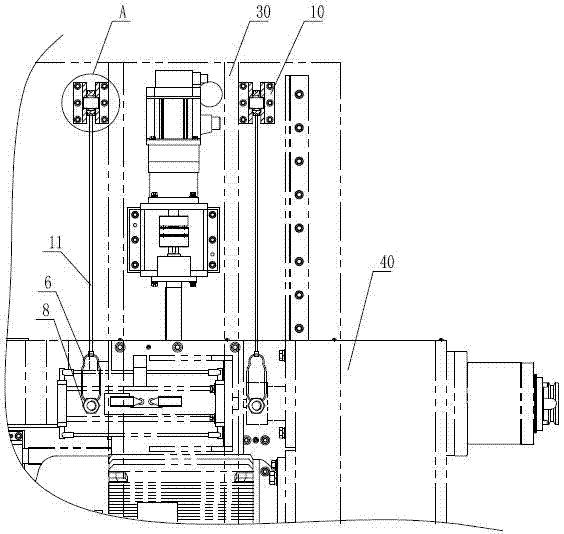

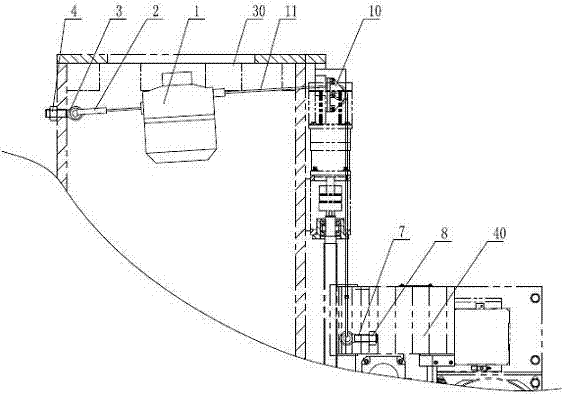

[0012] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

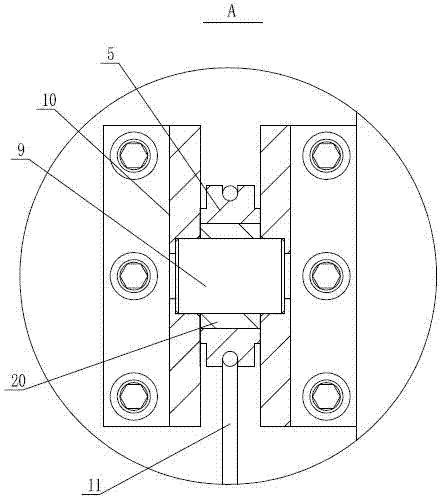

[0013] See figure 1 , figure 2 , the present invention includes a self-locking spring balancer 1, the two ends of the steel wire rope 11 in the body of the self-locking spring balancer 1 pass through the two sides of the housing of the self-locking spring balancer 1 respectively, and one side of the steel wire rope passes through the suspension The hook one 2 is connected to the joint of the joint bolt one 3, the joint bolt one 3 is fixed on the column assembly 30 through the nut one 4, and the steel wire rope on the other side passes through the connection between the hook two 6 and the joint bolt two 7 after winding around the roller 5 The joint is connected, and the joint bolt 2 7 is fixed on the drilling and milling head assembly 40 through the nut 2 8, and can move with the drilling and milling power head; see image 3 , the roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com