Continuous dynamic weighing chain belt type feeding machine

A dynamic weighing and chain-belt technology, which is applied in the direction of continuous material flow weighing equipment, weighing, conveyors, etc., can solve the problem of large maintenance of belt or armor belt feeders, and slippage of transmission belts and armor belts , belt feeder slipping and other problems, to achieve the effect of continuous trouble-free operation for a long time, improve weighing accuracy, and ensure accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

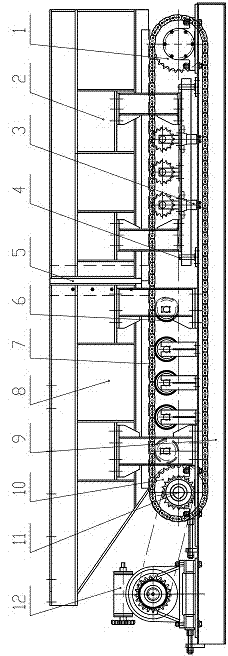

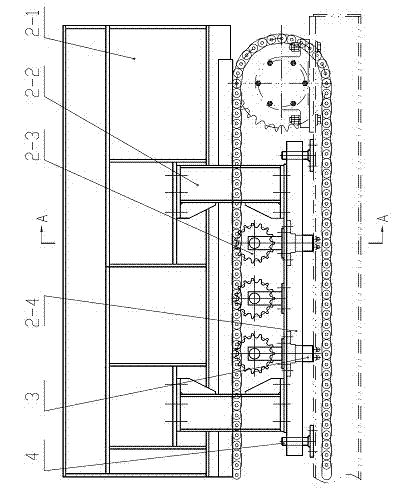

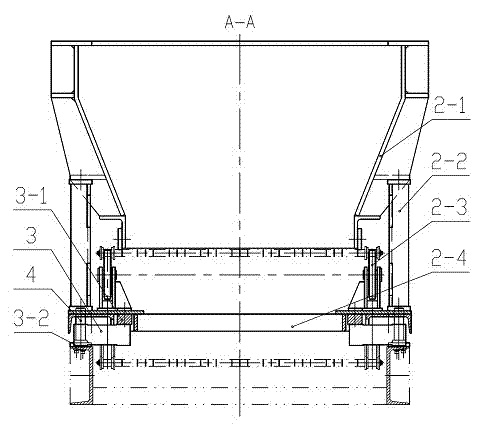

[0021] The continuous dynamic weighing chain-belt feeder of the present invention is mainly composed of a driving device 12, a driving sprocket group 10, a tensioning sprocket group 1, a combined chain belt 7, a base 9, a fixed guide groove 8, and a weighing body 2 , load cell 3, rotating speed sensor 11, pound body guide column 4 are formed. The combined chain belt 7 is divided into the combined chain belt of the feeding section, the combined chain belt of the return section, the combined chain belt of the weighing section and the sleeve roller chain of the weighing section. The upper section of combined chain belt between set 10 and tensioning sprocket set 1; the section of combined chain belt in the return section between drive sprocket set 10 and tensioning sprocket set 1; the weighing section The combined chain belt is located at the part of the feedi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com