Micro-vibration energy-consumption viscoelastic buckling restrained brace

A buckling constraint and viscoelastic technology, applied in building components, shockproof and other directions, can solve problems such as inability to consume energy, and achieve the effect of simple installation, simple production, convenient and flexible installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

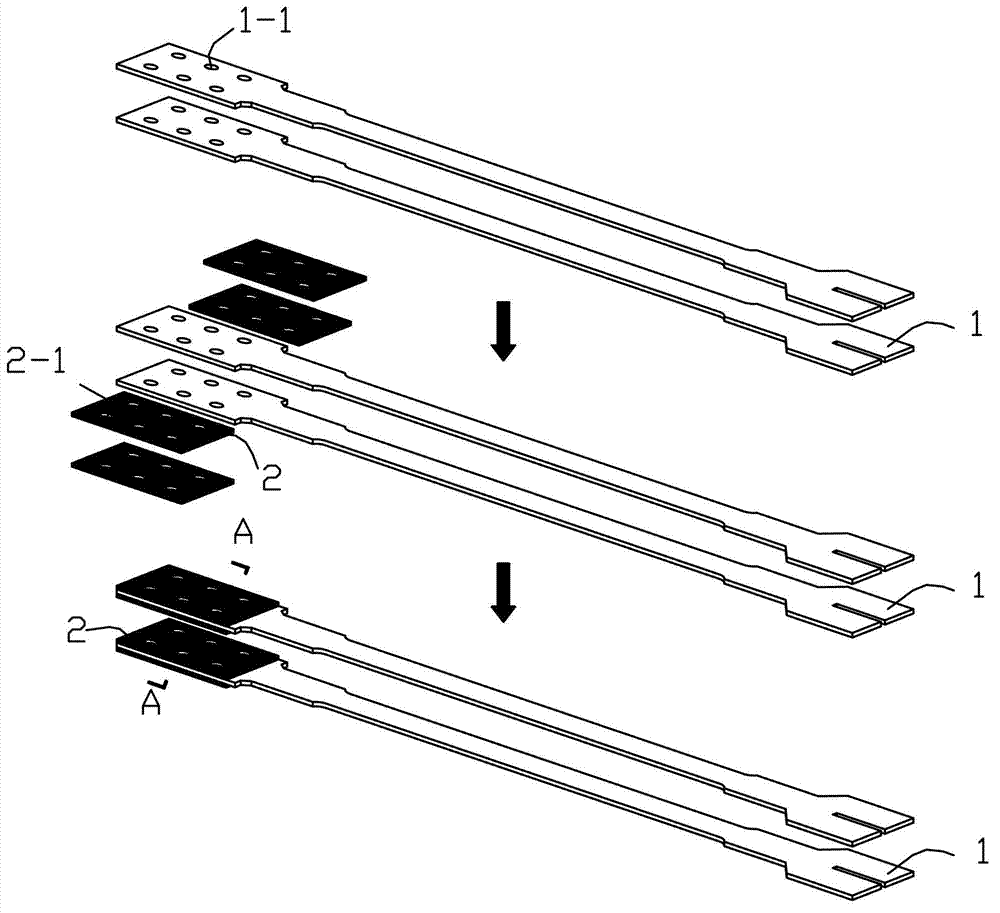

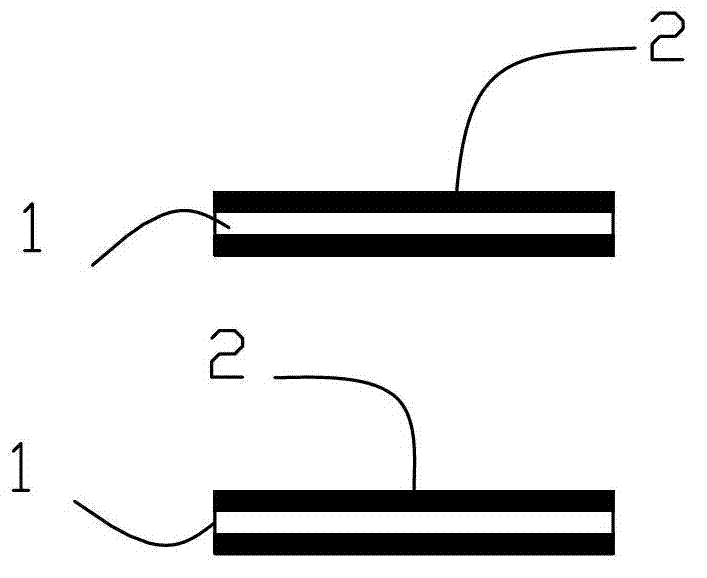

[0028] Embodiment one: if Figure 1~9 As shown, the micro-vibration dissipative energy-dissipating viscoelastic buckling constrained support of this embodiment is composed of two energy-dissipating inner core plates 1, a viscoelastic material body 2, a buckling constraining component 3, and a restraining force-transmitting component 4. One end of the core plate 1 is provided with several first deformation holes 1-1, wherein the deformation holes 1-1 can be oval holes, oblong holes, waist-shaped holes or elongated holes, etc., in this embodiment, the first The deformation hole 1-1 is an elliptical hole, and the end of the energy-dissipating inner core plate 1 with the elliptical hole is located in the restraining force transmission part 4, and the middle section of the energy-dissipating inner core plate 1 is located in the buckling restraining part 3, and the energy-dissipating inner core plate The other end of 1 protrudes outside the buckling constraining part 3, and the visc...

Embodiment 2

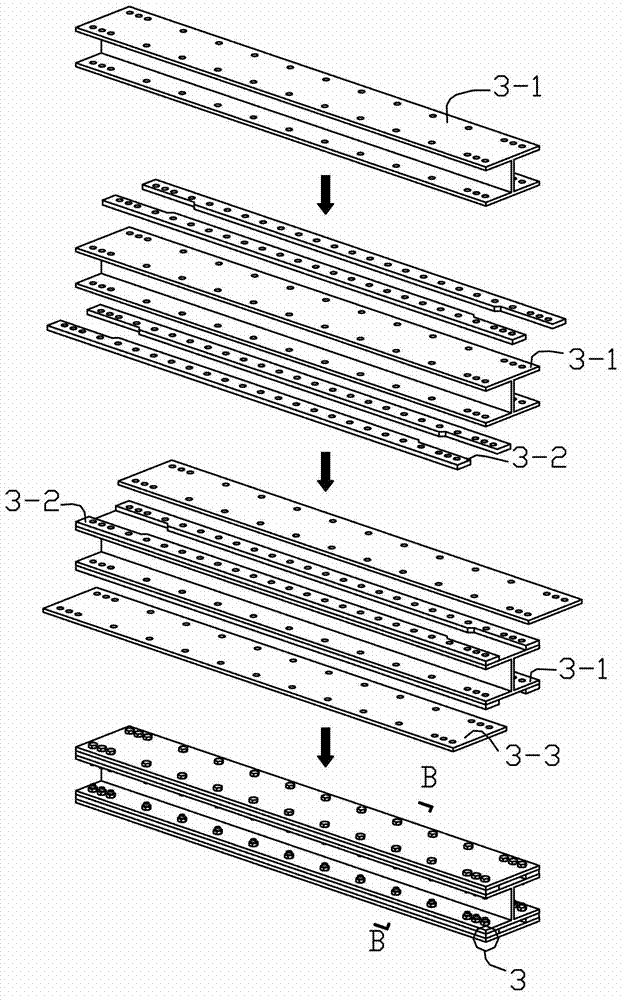

[0029] Embodiment two: if image 3 As shown, the shape of each first filling plate 3-2 in this embodiment corresponds to the side shape of each energy-dissipating inner core plate 1, and each filling plate 3-2 is located on the first I-shaped steel plate 3-1. And in the middle of the two first cover plates 3-3, every two first filling plates 3-2 are located on the upper and lower surfaces of the first I-shaped steel 3-1, and the outside of every two first filling plates 3-2 is a The gap between the first cover plate 3-3, the first filling plate 3-2 and the first cover plate 3-3 and the energy dissipation inner core plate 1 is about 1-2mm, and the in-plane and Out-of-plane buckling. Other compositions and connection methods are the same as those in Embodiment 1.

Embodiment 3

[0030] Embodiment three: as Figure 5 As shown, each filling plate 4-2 of this embodiment is located in the middle of the second I-shaped steel 4-1 and the two second cover plates 4-3, and every two second filling plates 4-2 are located in the middle of the second I-shaped steel plate 4-1. The upper and lower surfaces of the glyph steel 4-1, the outside of every two second filling plates 4-2 is a second cover plate 4-3, the second filling plate 4-2, the second cover plate 4-3 and the second working plate The space formed by the font-shaped steel 4-1 is 1-2mm wider than the viscoelastic material body 2, which plays a role in protecting the viscoelastic material body 2. Other compositions and connection methods are the same as those in Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com