wall plaster grinding machine

A technology of a surface grinding machine and a grinding disc, which is applied in the direction of construction and building structure to achieve the effect of saving labor, improving production efficiency and speeding up construction progress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation method of the utility model is: one day before the grouting, the wall material and dryness of the wall surface to be grouted are understood, and the water-cement ratio of the mortar prepared by different wall materials is different, and additives need to be added when necessary , For the wall that is too dry, it needs to be wetted with water one day before plastering. For the wall that is too wet and does not absorb water, it is necessary to add additives when preparing mortar. Trimming.

[0024] The specific implementation of the utility model is carried out in the following order:

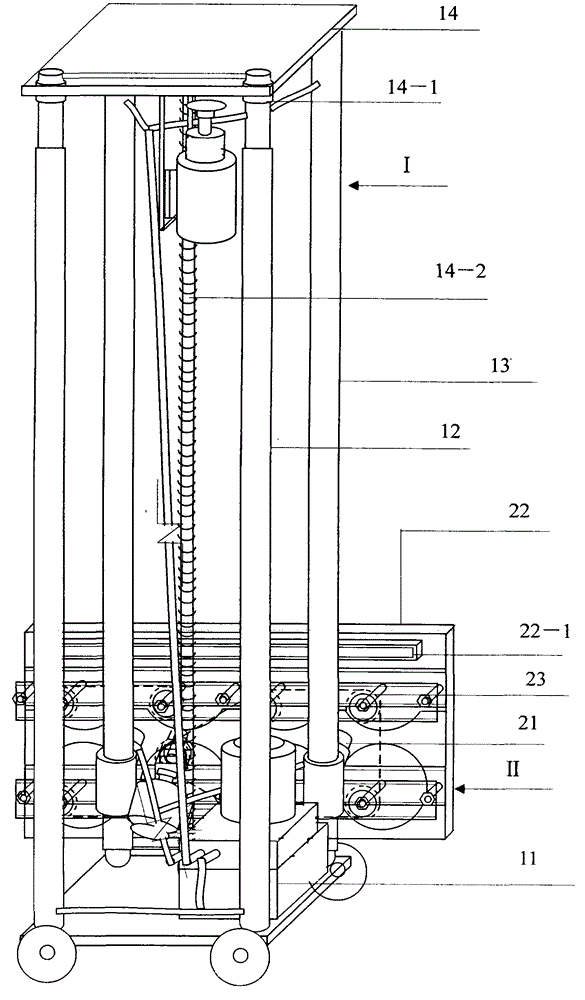

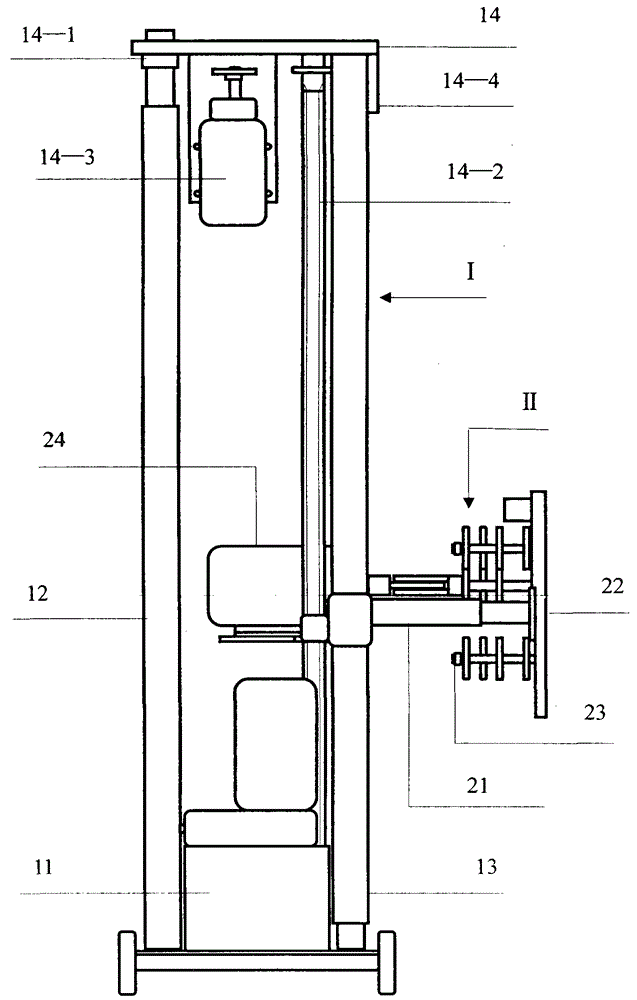

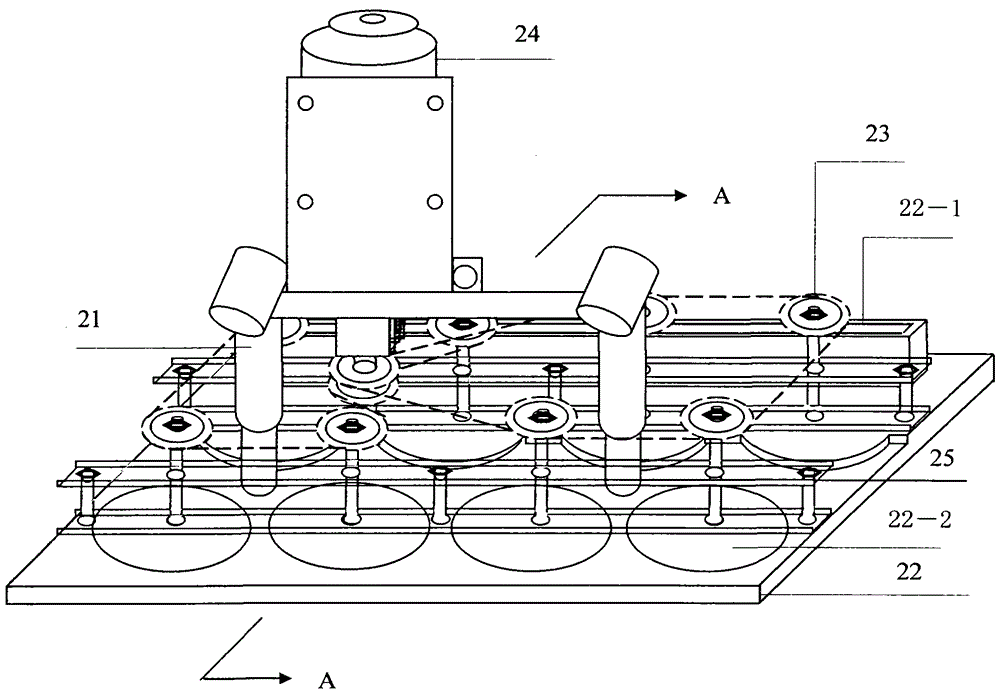

[0025] 1. Place the frame (I) basically parallel to the wall to be grouted, turn on the infrared rangefinder (14-4) and start the power transmission system (11), turn on the telescopic arm transmission system, and let the telescopic arm (21) push out the grinding disc Assembly (II) to the top, according to the reading on the infrared distance meter (14-4), ligh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com