Working well-free heading machine synchronous grouting simulation test platform

A simulation test and synchronous grouting technology, applied in wellbore lining, shaft equipment, tunnel lining, etc., can solve problems such as inability to measure soil surface displacement, test, and inability to simulate grouting process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

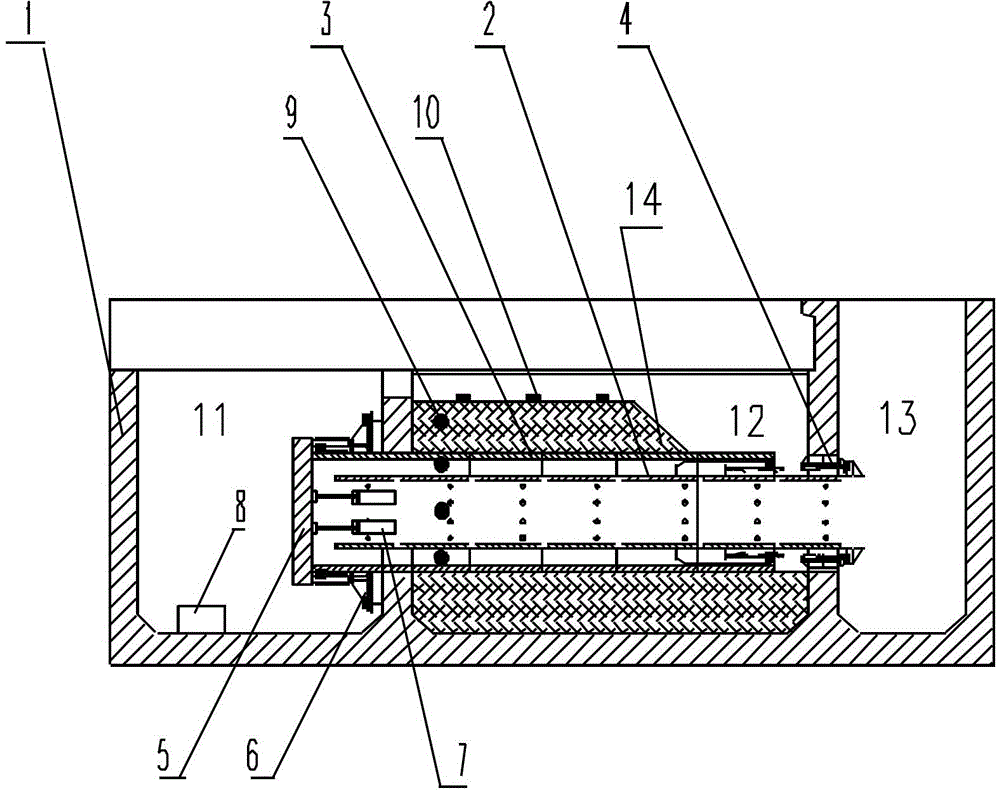

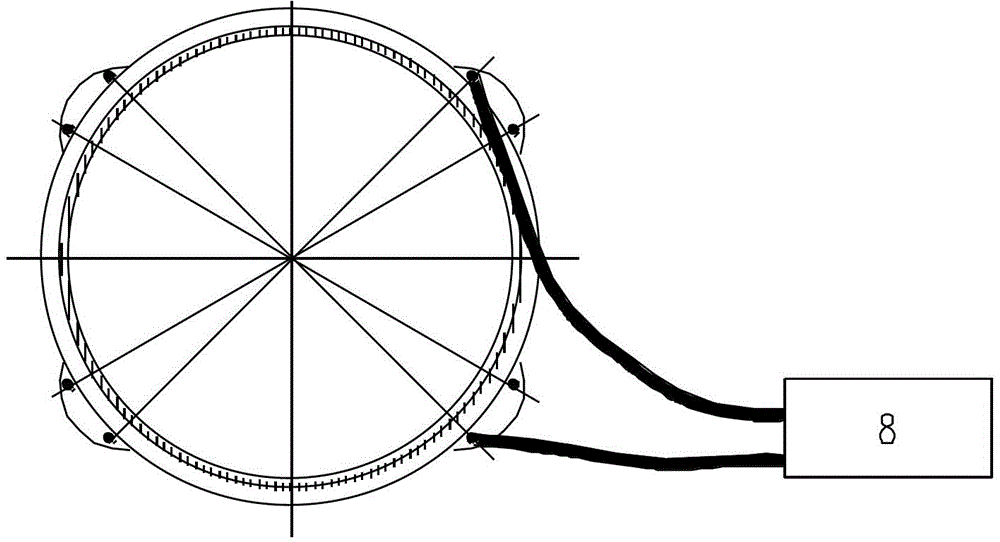

[0027] see figure 1 Structural schematic diagram of the present invention, the diagram shows that the synchronous grouting simulation test platform of the shield tunneling machine without working well includes a large-scale sinking comprehensive test bench 1, a simulated segment 2, a simulated shield tail 3, a connecting flange 4, a beam 5, Circular hole door 6, hydraulic cylinder 7, grouting pump 8, earth pressure box 9 and surface displacement gauge 10.

[0028] The large-scale sunken comprehensive test bench 1 is a square structure made of concrete, sunk into the ground, with dimensions of 22.4m in length, 9.6m in width, and 9.3m in depth. The originating shaft 11, the filling well 12 and the receiving well 13; the well wall between the starting shaft 11 and the filling well 12 and the well wall between the receiving well 13 and the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com