Waterproof structure of shield tunnel segment

A shield tunnel segment and waterproof structure technology, applied in tunnels, tunnel linings, shaft linings, etc., can solve problems such as groundwater seepage into the tunnel, unfavorable treatment measures, affecting tunnel operation and service life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

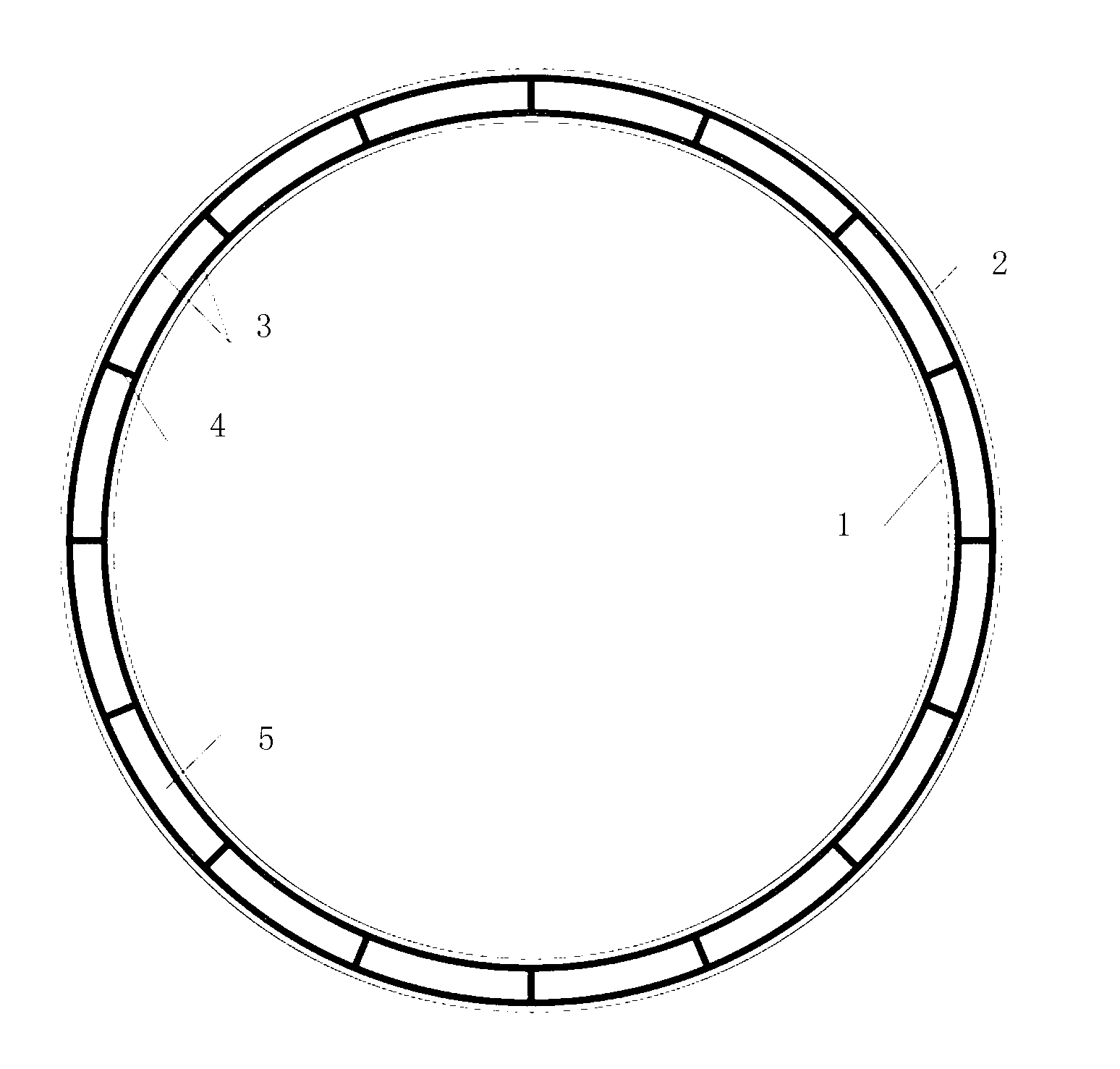

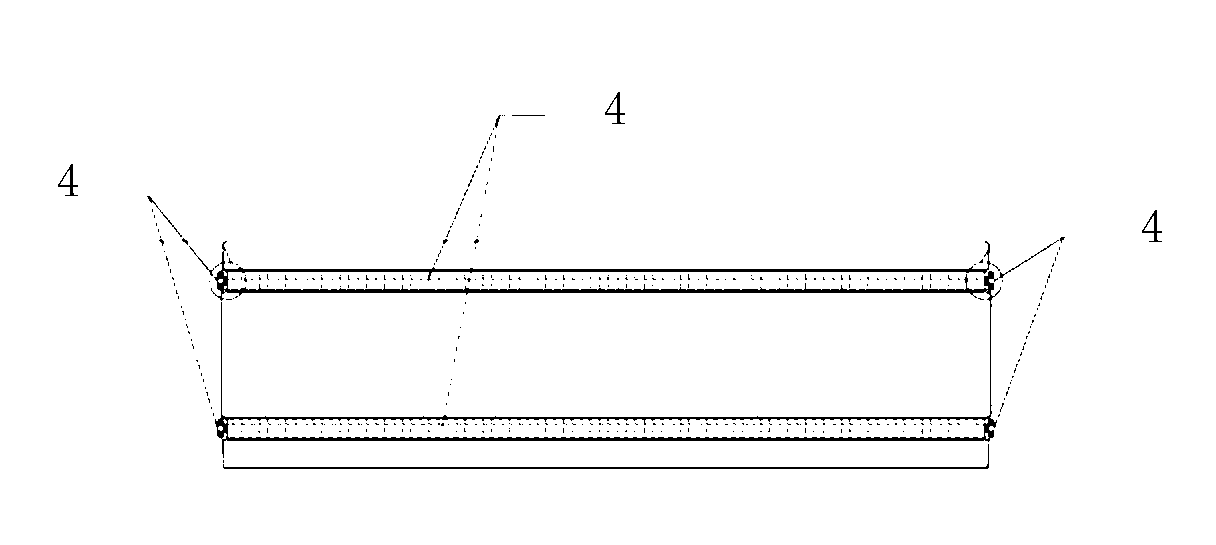

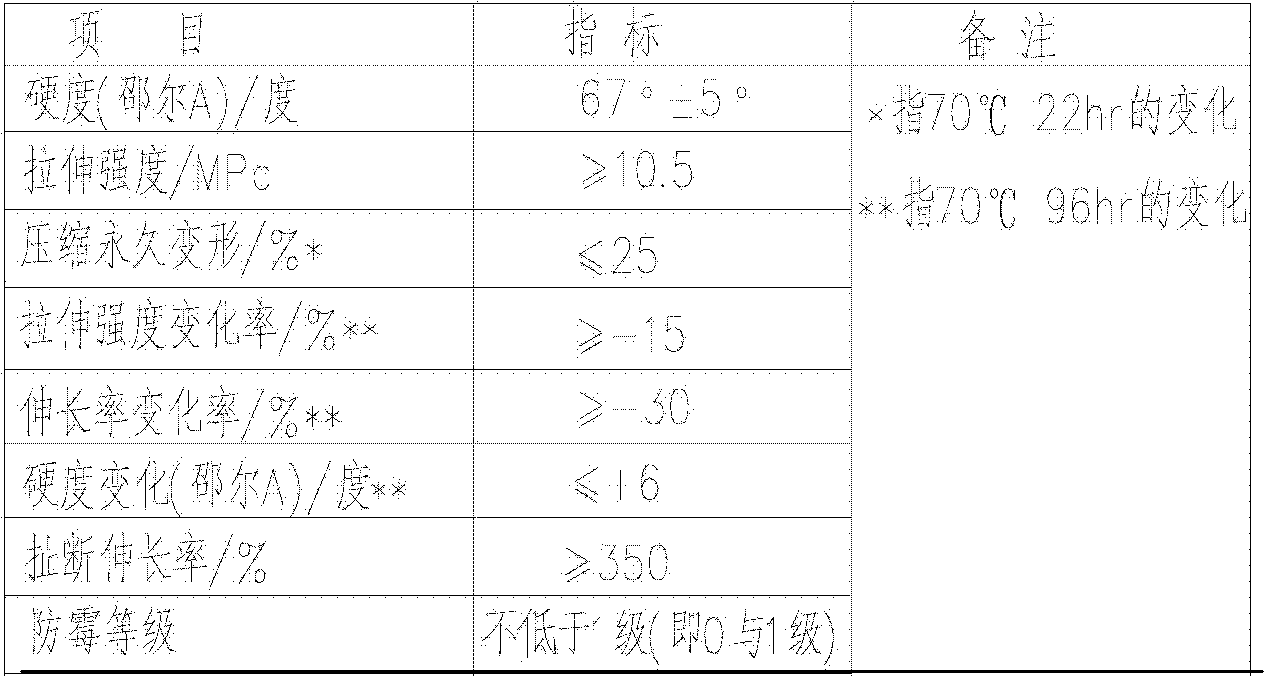

[0012] There are 16 circular seam vertical waterproof belts perpendicular to the circular seam waterproof belts between the two parallel circular seam waterproof belts, and the circular seam vertical waterproof belts separate the two circular seam waterproof belts into 16 waterproof partitions. There are two parallel longitudinal seam waterproof belts in the shield segment, and the longitudinal seam waterproof belt and the circular seam waterproof belt vertically and seamlessly intersect. The width of the longitudinal seam waterproof belt is 24mm, and the thickness is 16mm. The width of the circular seam waterproof belt is 24mm, and the thickness is 16mm. The distance between the two longitudinal seam waterproof belts is the same as the distance between the two circular seam waterproof belts, and the position of the longitudinal seam waterproof belt corresponds to the position of the circular seam waterproof belt. The circular seam waterproof belt, the circular seam vertical w...

Embodiment 2

[0017] Between the two parallel circular seam waterproof belts, there are three circular seam vertical waterproof belts perpendicular to the circular seam waterproof belts, and the circular seam vertical waterproof belts separate the two circular seam waterproof belts into 3 waterproof partitions. There are two parallel longitudinal seam waterproof belts in the shield segment, and the longitudinal seam waterproof belt and the circular seam waterproof belt vertically and seamlessly intersect. The width of the longitudinal seam waterproof belt is 45mm, and the thickness is 22mm. The width of the circular seam waterproof belt is 45mm, and the thickness is 22mm. The distance between the two longitudinal seam waterproof belts is the same as the distance between the two circular seam waterproof belts, and the position of the longitudinal seam waterproof belt corresponds to the position of the circular seam waterproof belt. The circular seam waterproof belt, the circular seam vertica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com