Method of manufacturing a transmission clutch assembly with reduced squawk

A manufacturing method and transmission technology, applied in the directions of intermeshing clutches, clutches, fluid-driven clutches, etc., can solve problems such as low efficiency and energy loss, and achieve the effects of reducing whistling, reducing annoying noise, and wide-ranging vibration reduction effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

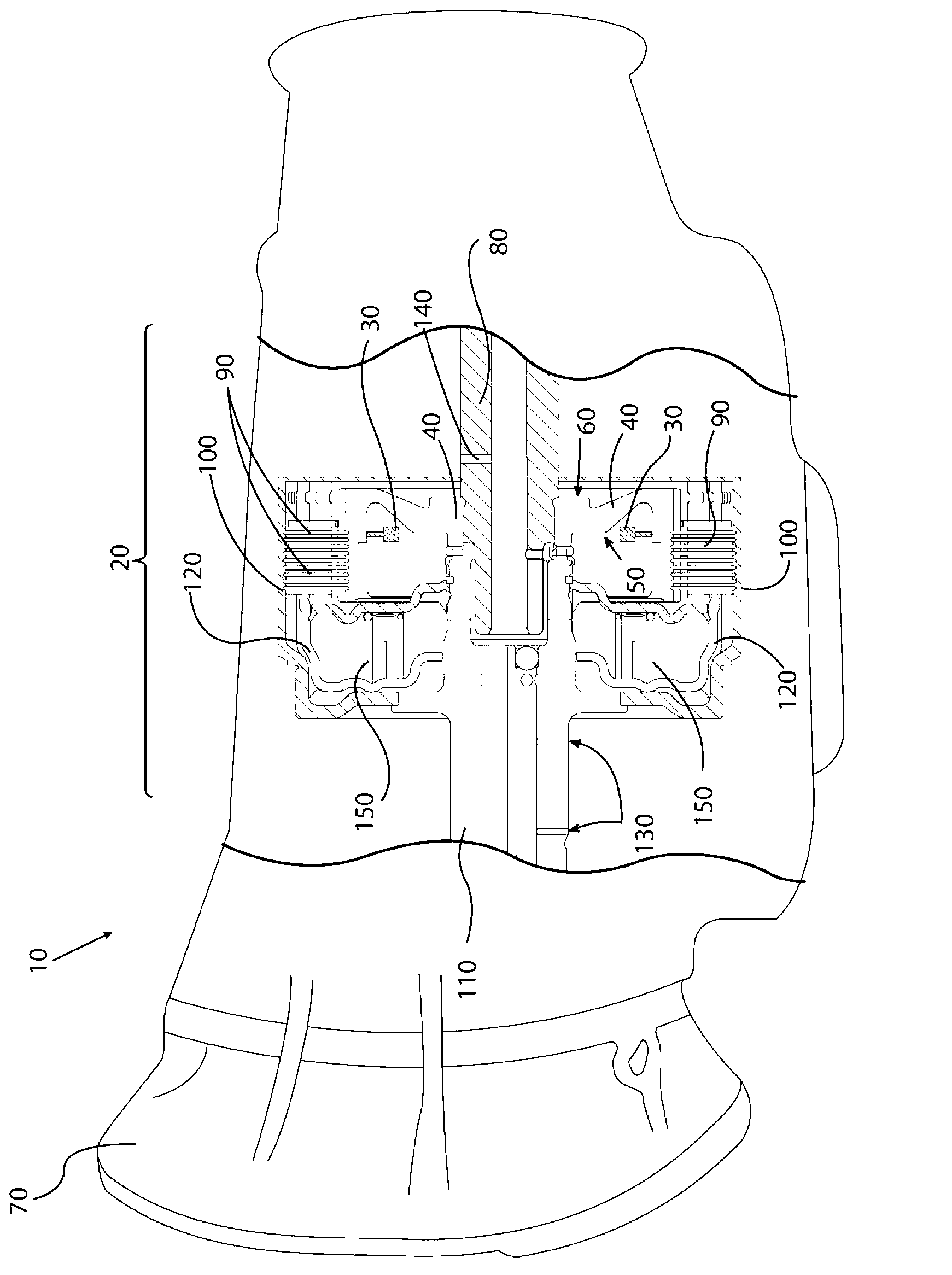

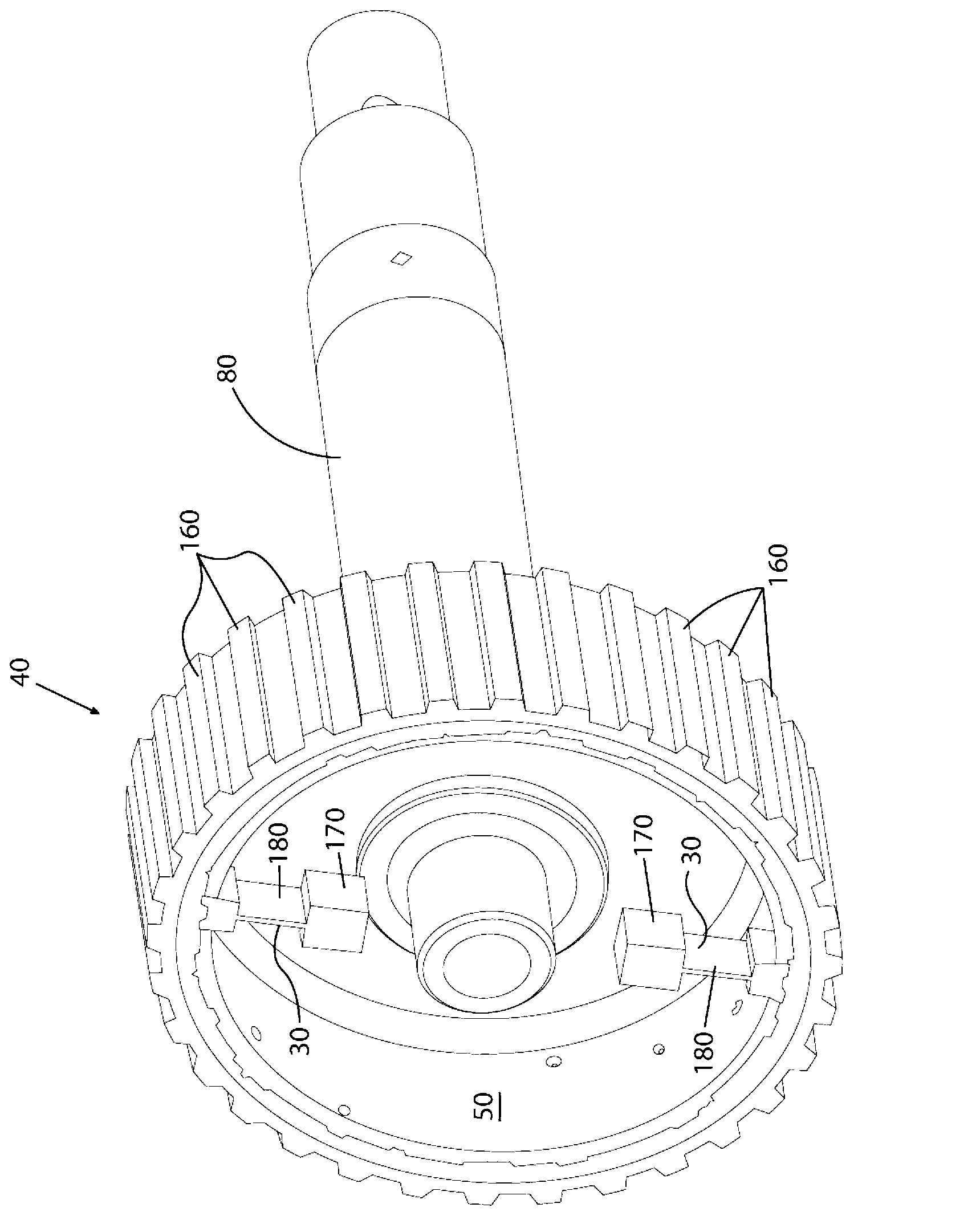

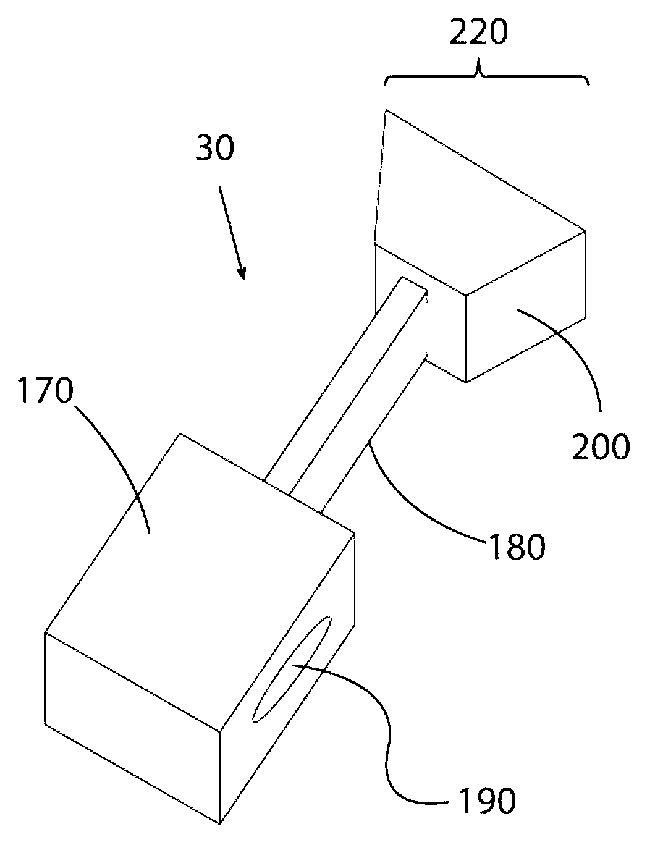

[0022] Referring to the drawings, there are shown different embodiments of a vehicle transmission having a clutch assembly with improved howl reduction capability, like symbols designating like or corresponding parts throughout the views. Significant noise reduction is achieved through the use of a set of mass dampers in the clutch assembly. In one embodiment, for example, the damper is a sprung mass damper coupled to a clutch gear. The mass damper changes the vibration pattern of the clutch gears during engagement, thereby reducing the noise output during shifting. The two runners (also called receivers or grooves) are 180 degrees apart on the clutch gear. Both dampers are press fit into the slots to connect the dampers to the clutch gear. This manufacturing method yields the added lubricating advantage that when the mass damper is coupled in the clutch gear, a lubricant seal is formed between one side of the clutch gear and the other side of the clutch gear.

[0023] In c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com