Assessment method for geometric errors of five-axis tool machine

A technology of tool machinery and geometric error, which is applied in the evaluation field that can measure and calculate the geometric error of five-axis tool machinery. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The technical contents and features of the present invention will be described in detail below in conjunction with the accompanying drawings through the enumerated embodiments, wherein:

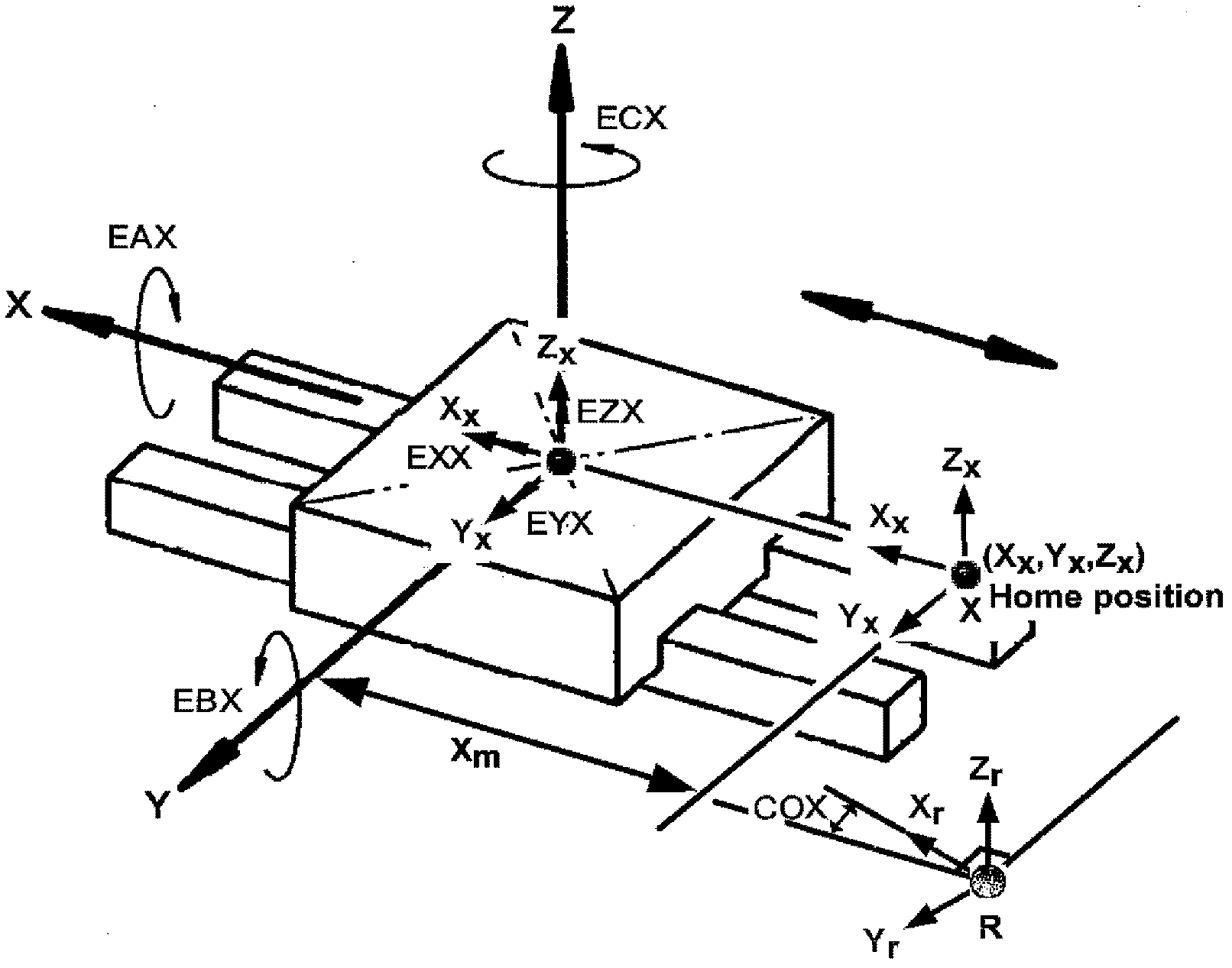

[0050] figure 1 A schematic diagram of the model definition for the geometric error of the X linear motion axis of the present invention;

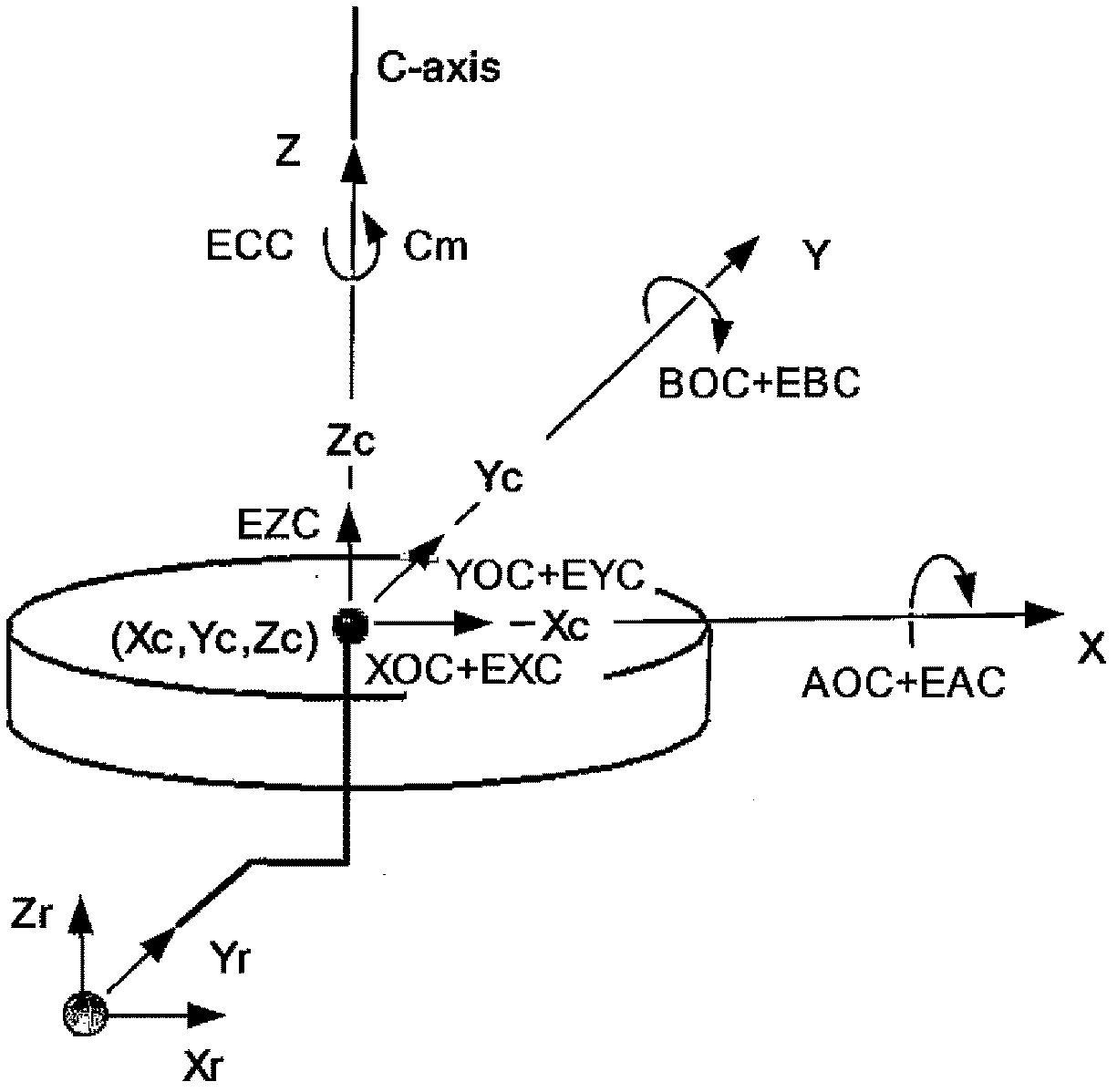

[0051] figure 2 A schematic diagram of the model definition for the geometric error of the C rotation axis of the present invention;

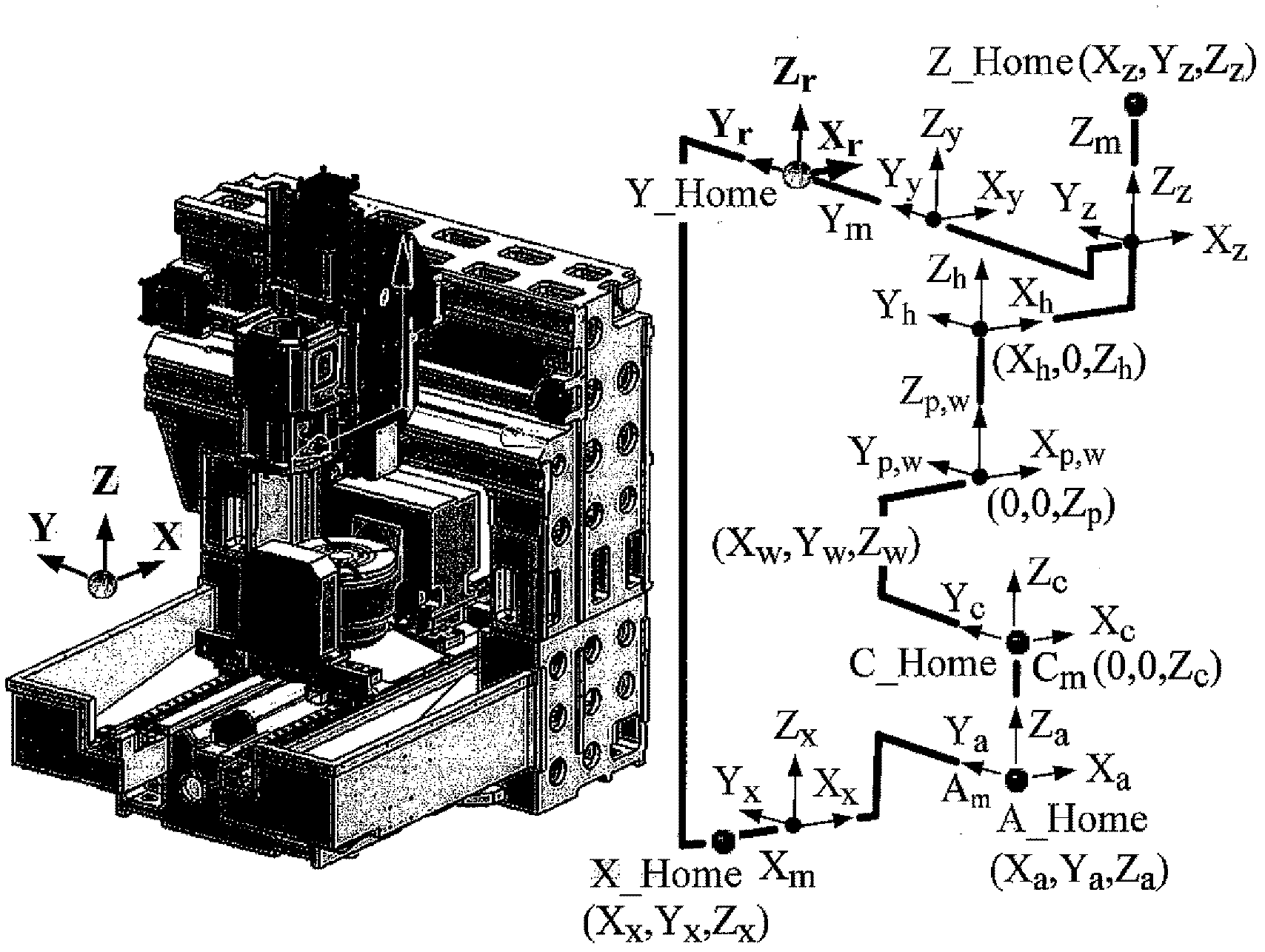

[0052] image 3 A schematic diagram of the coordinate system formed by erecting the R-test measuring tool on the five-axis tool machine for the present invention;

[0053] Figure 4 Utilize R-test gauge to measure the schematic diagram of gained assembly error for the present invention;

[0054] Figure 5 It is a comparison diagram of the error value after measurement and calculation by using the K4 path in a preferred embodiment of the present invention.

[0055] see figure 1 , the geometric error of tool ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com