Pipeline liquid level sensor for mine

A liquid level sensor and pipeline technology, applied in the field of flow sensors, can solve the problems of liquid flow interference, damage, misjudgment, etc., and achieve the effects of stable working performance, safe and reliable use, and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

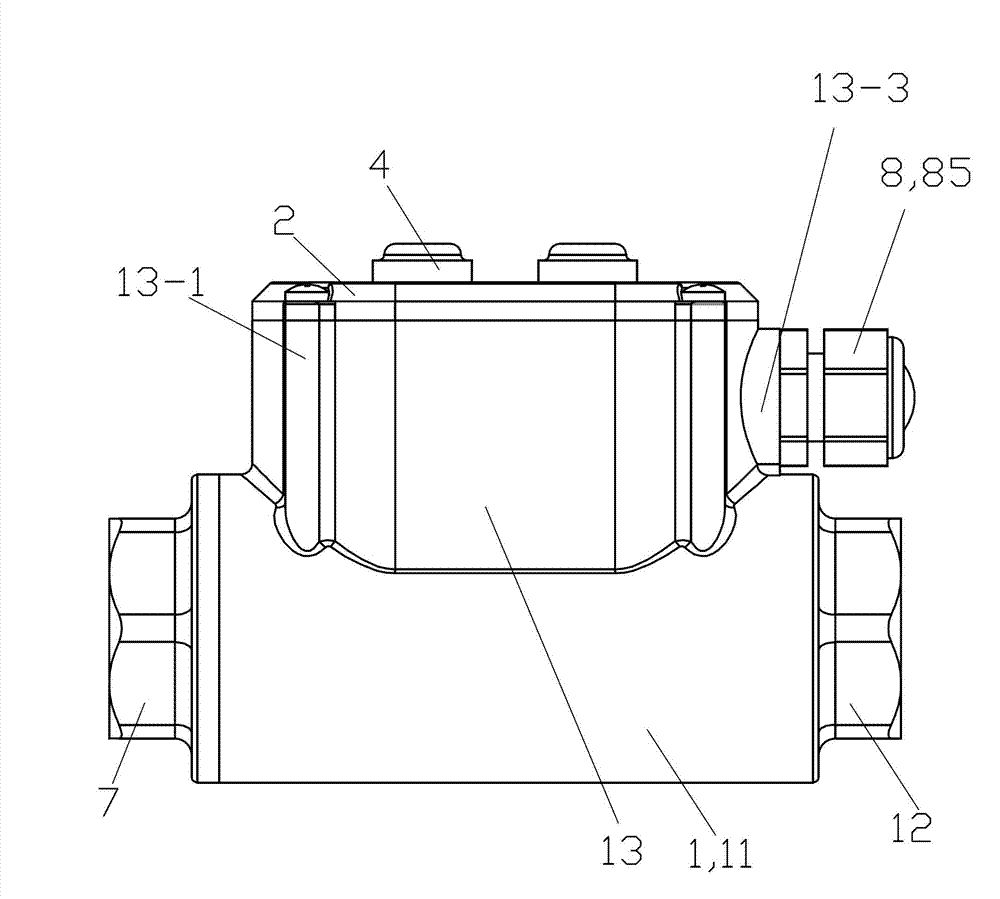

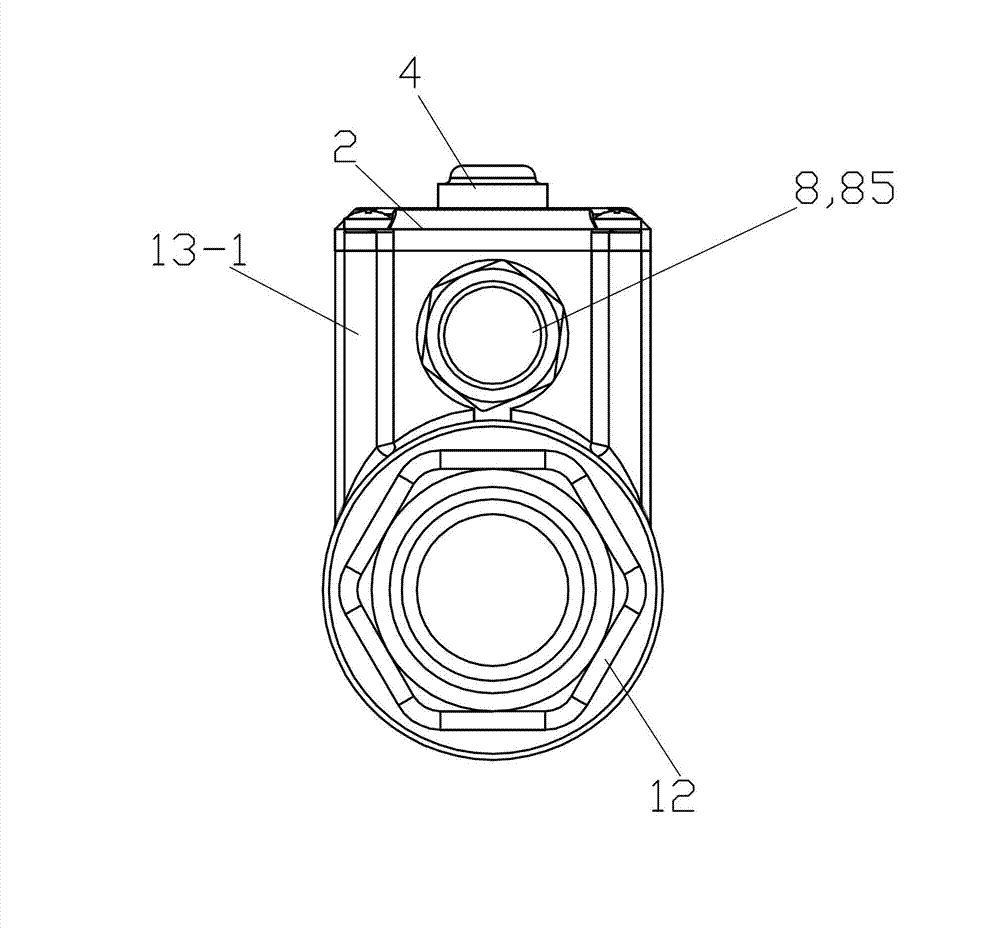

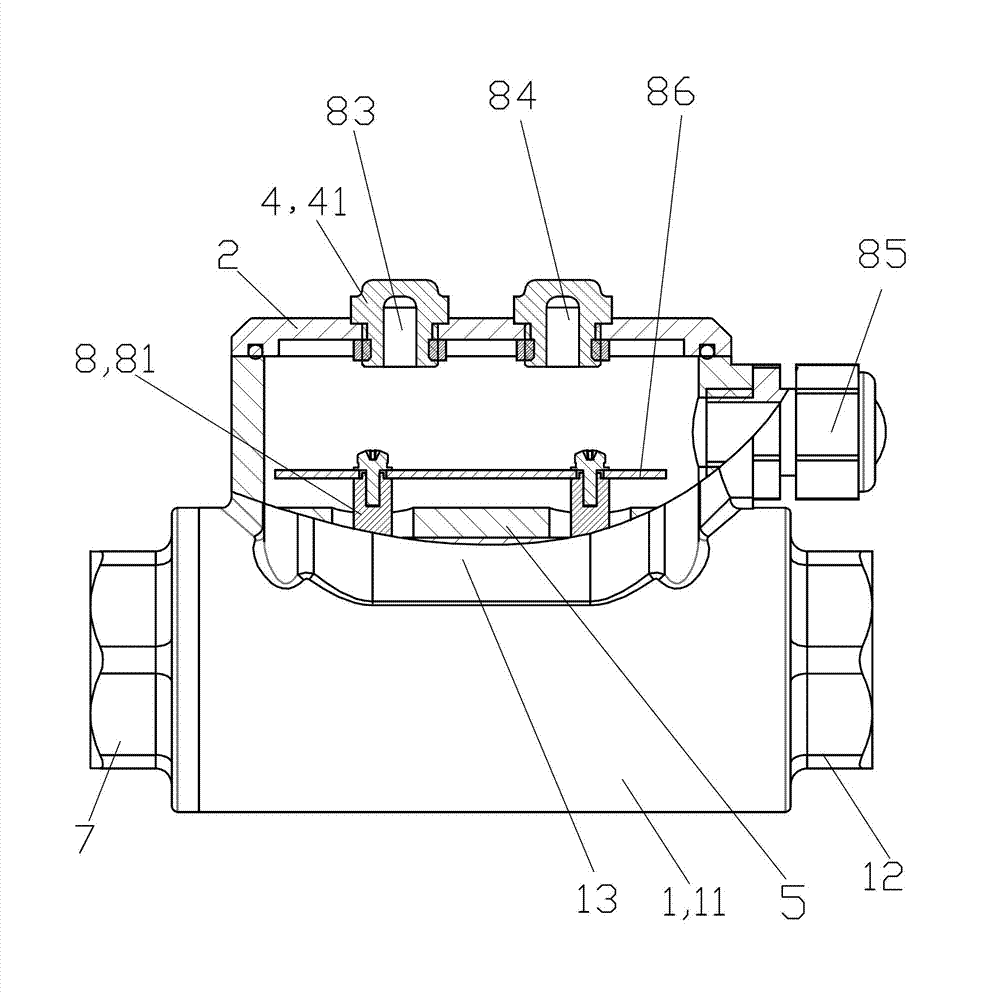

[0033] See Figure 1 to Figure 5 , The mine pipeline liquid level sensor of this embodiment is composed of a base body 1, a cover plate 2, a sealing assembly 3, a lampshade assembly 4, a lining 5, a fastener 6, an adapter assembly 7 and a circuit device 8.

[0034] The base body 1 is a cast stainless steel integral piece. The base body 1 is integrally composed of a cylindrical part 11 , a pipe connection part 12 and a mounting part 13 .

[0035] The cylinder portion 11 of the base body 1 is a hollow cylinder, and its upper end is provided with an opening consistent with the lower end opening of the installation portion 13, and the pipe connection portion 12 is arranged on the right end of the cylinder portion 11, and the pipe at the right end of the pipe connection portion 12 The inner wall is provided with an internal thread for connecting with the underground liquid pipeline, and the inner wall at the left end of the cylinder part 11 is provided with an internal thread for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com