Two-dimensional bar code scanning method and system

A two-dimensional barcode, to-be-scanned technology, applied in the field of scanning two-dimensional barcodes, can solve the problems of manual image manipulation, expensive scanning guns, and inability to meet the needs of factory automation operations, and achieves the effect of meeting the needs of automated operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

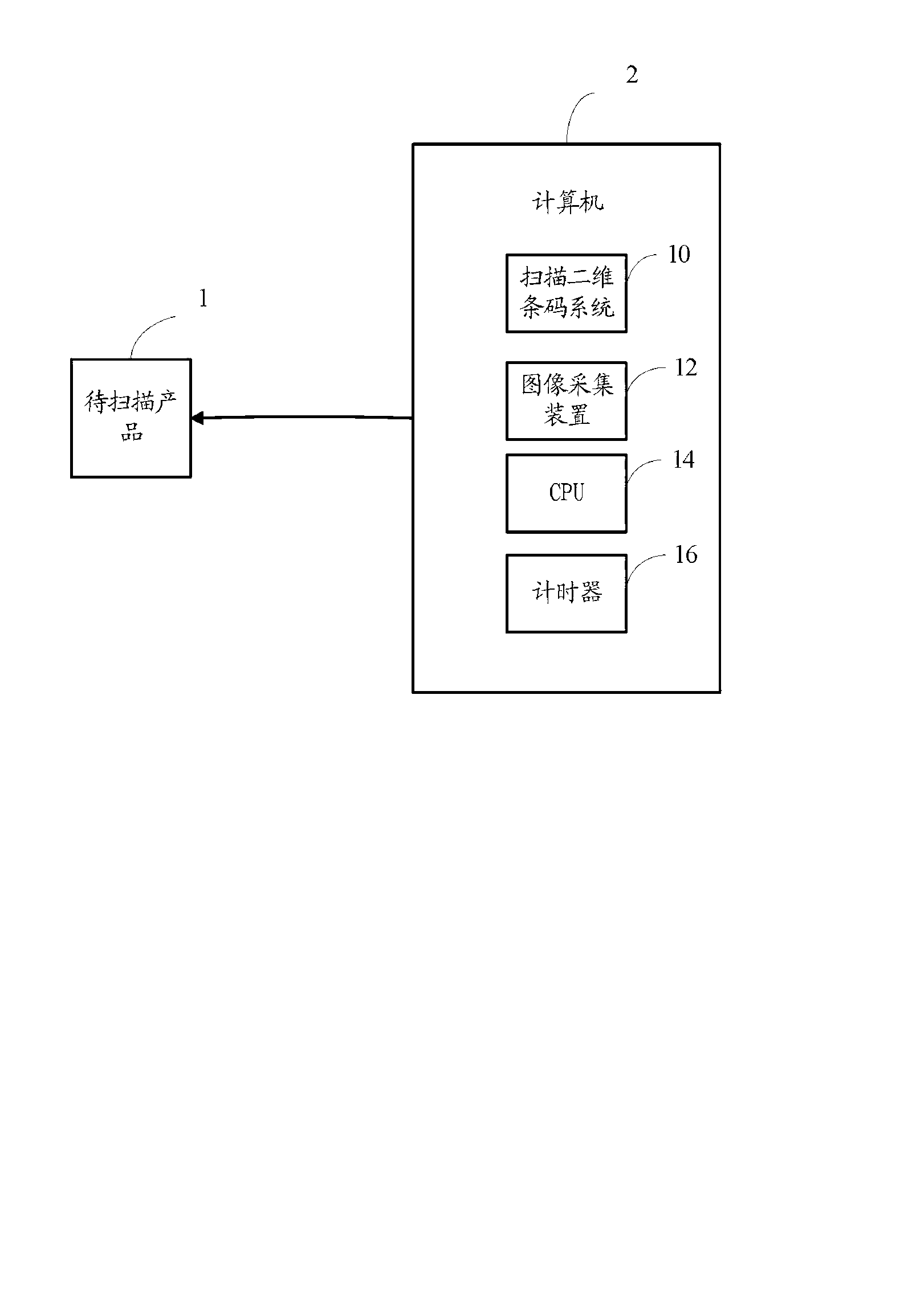

[0014] Such as figure 1 It is an operating environment diagram of the 2D barcode scanning system of the present invention. The 2D barcode scanning system 10 runs on a computing device, such as a computer 2. The 2D barcode scanning system 10 is used to scan the 2D barcode of the product 1 to be tested. The product 1 to be tested may be electronic products such as smart phones, tablet computers, and personal digital assistants.

[0015] The computer 2 is equipped with an image acquisition device 12 , a CPU 14 , and a timer 16 . The image acquisition device 12 is used to acquire the two-dimensional barcode picture of the product 1 to be scanned. In this embodiment, the image acquisition device 12 may be a camera. CPU 14 is the calculation center and control center of the computer, and is used to control the operation of the system. The timer 16 is equivalent to a clock. When the program is running, the timer 16 will trigger a timing event every time a set time interval passes. ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap