Etching device

An etching device and etching technology, applied in transportation and packaging, conveyor objects, electrical components, etc., can solve problems such as damage, affecting accuracy, and falling wafers 90

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to understand the technical characteristics and practical effects of the present invention in detail, and to implement them according to the contents of the instructions, the preferred embodiment shown in the figure will be described in detail as follows:

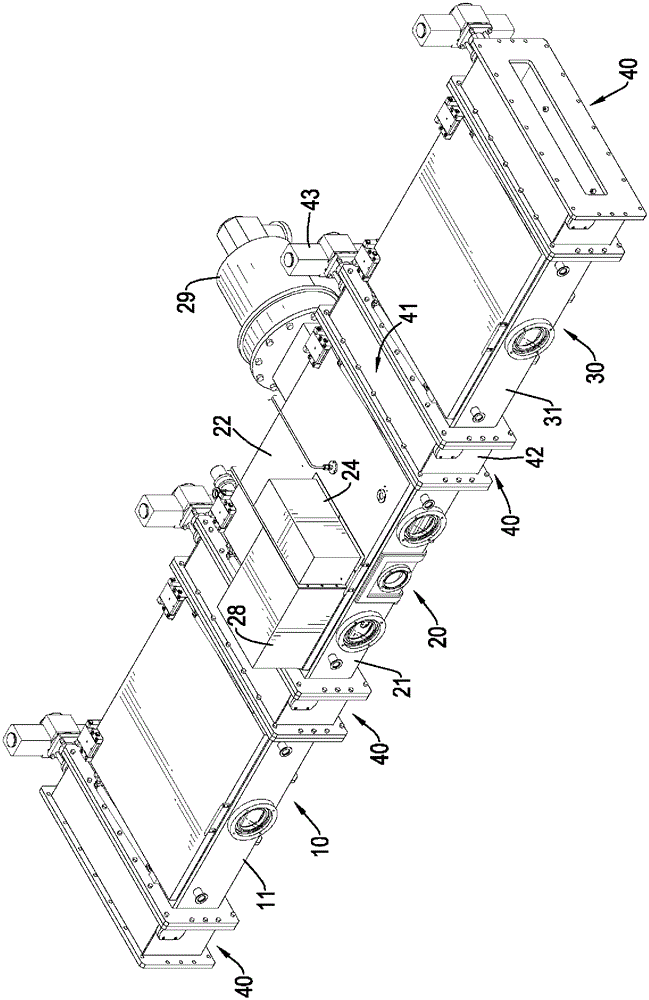

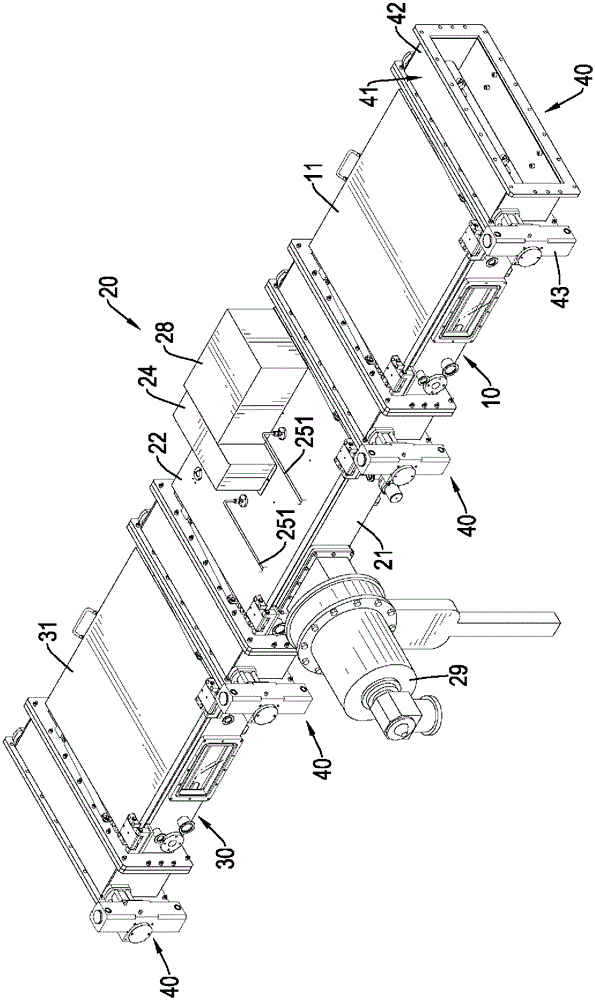

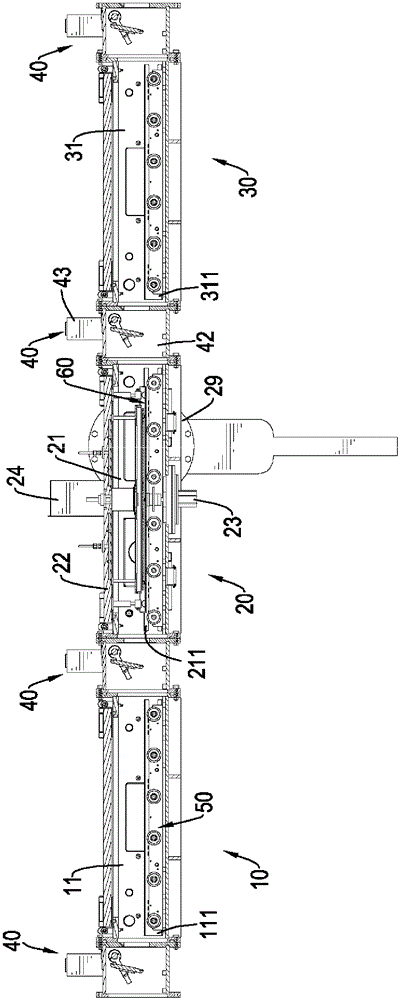

[0054] The present invention mainly provides an etching device, please refer to Figures 1 to 3 As shown, it can be seen that the etching device of the present invention is provided with a feed assembly 10, an etching assembly 20, a discharge assembly 30, a valve assembly 40, a delivery assembly 50 and a carrier assembly 60 by the figure, wherein :

[0055] The feeding assembly 10 is provided with a feeding chamber 11, which is a roughly rectangular hollow chamber. The body 11 is provided with a first guide rail 111 on both sides of the interior. Further, the feed assembly 10 is connected to a vacuum pump (not shown), so that the feed chamber 11 maintains a vacuum state;

[0056] For further cooperation, p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com