Method for suppressing waving of extra-high voltage bundled conductor

A wire galloping and multi-splitting technology, applied in the field of electric power transmission, can solve the problems such as the inability to prevent uneven formation of icing and the poor anti-galloping effect, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

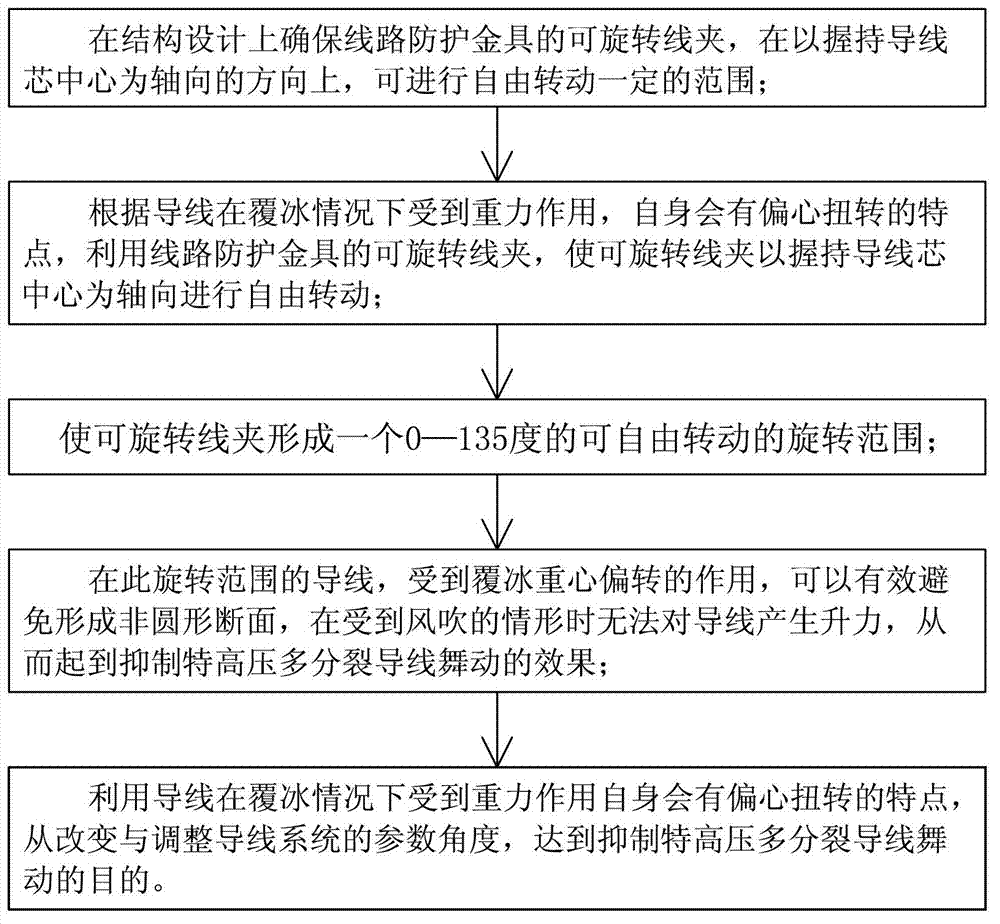

[0040] The present invention will be further described below.

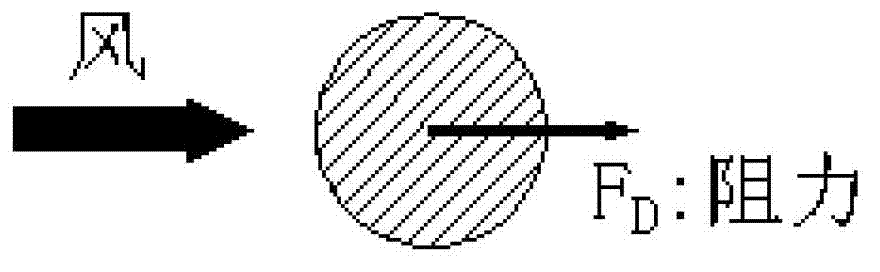

[0041] figure 1 As shown in the figure, it can be seen that because the outer circumference of the wire is circular, it forms a circular cross section, and the flowing air / wind does not produce lift or torque on the wire, so the wire does not vibrate up, down, left, or right. swing.

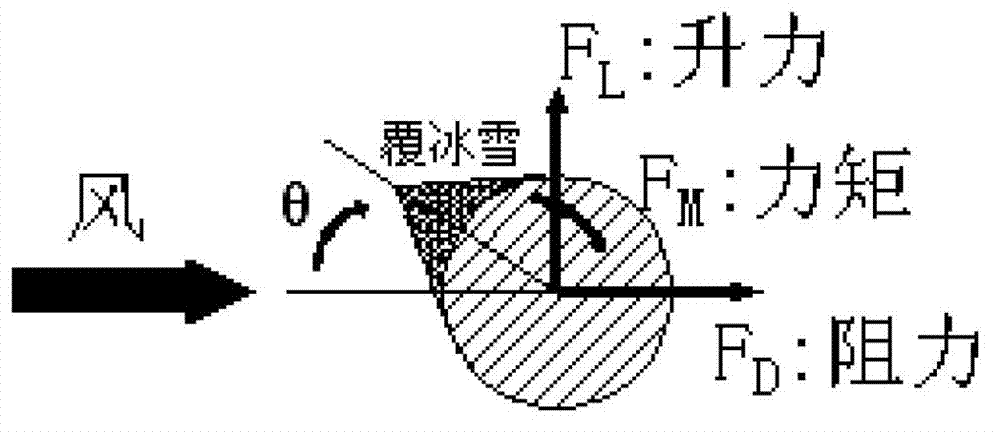

[0042] figure 2 , when the conductor is covered with ice and snow, the conductor is subjected to the combined action of forces from three directions (F in the figure L is the lift force, F M is the torque, F D for resistance).

[0043] The necessary conditions for analyzing these three forces are the aerodynamic coefficients (drag coefficient CD, fluid lift coefficient CL, torque coefficient CM).

[0044] The research on the galloping of transmission line conductors abroad has started since the 1930s, and the representative research results are the vertical galloping mechanism of Den Hartog in the United States and the twistin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com