Device and method for cool drying a gas

A technology of cooling and drying equipment, which is applied in the direction of chemical instruments and methods, mechanical equipment, separation methods, etc., can solve the problem of not getting the best cooling, and achieve the effect of small pressure dew point change and good drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

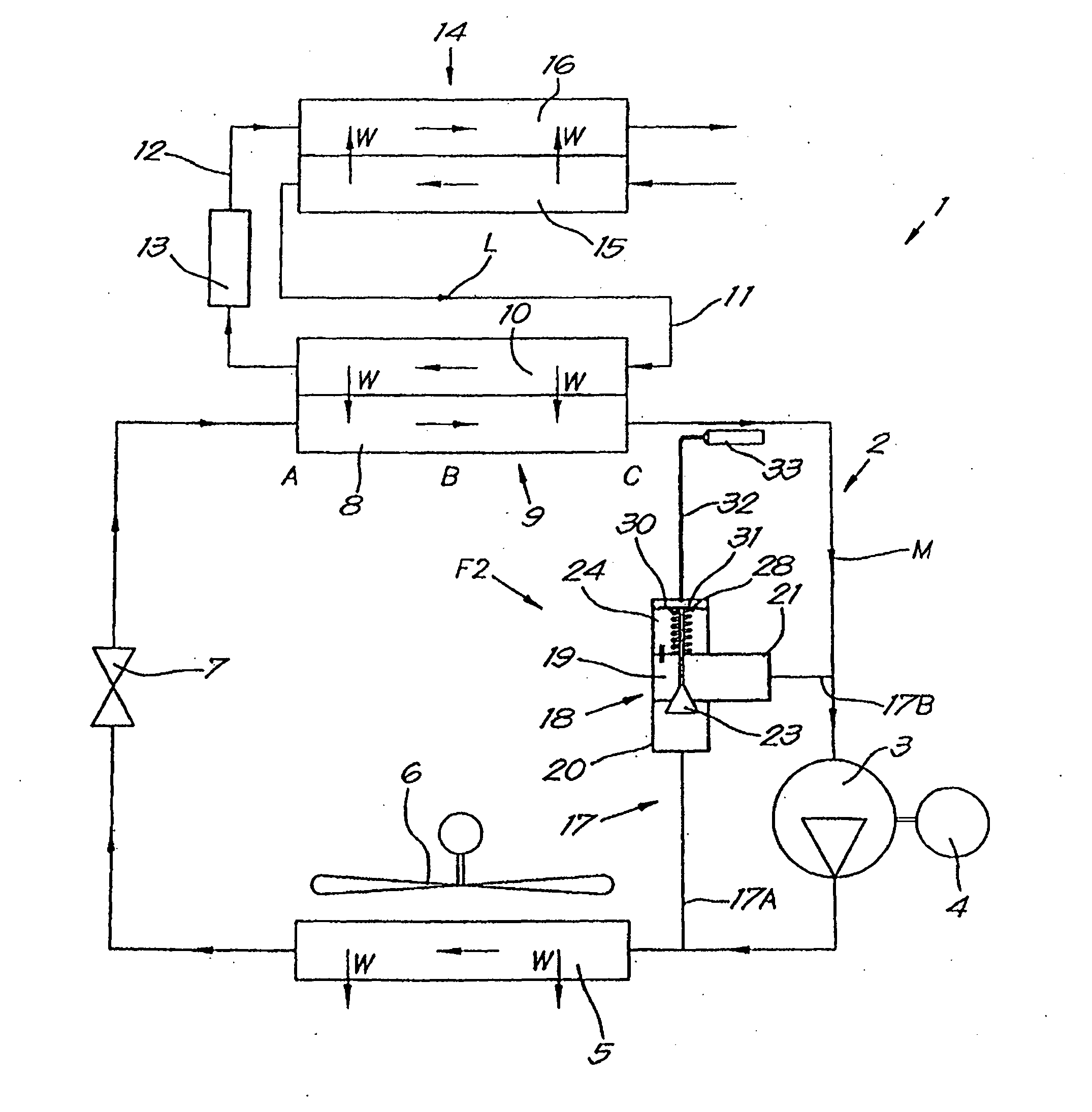

[0039] A known device 1 for cooling dry gas shown in FIG. 1 comprises a cooling line 2 containing a coolant which may be driven by a motor 4 or similar, preferably but not necessarily a constant speed motor. Compressor 3 circulates in the pipeline.

[0040] The flow direction of the coolant in the pipe is indicated by the arrow M. Upstream and downstream are defined according to the flow direction M.

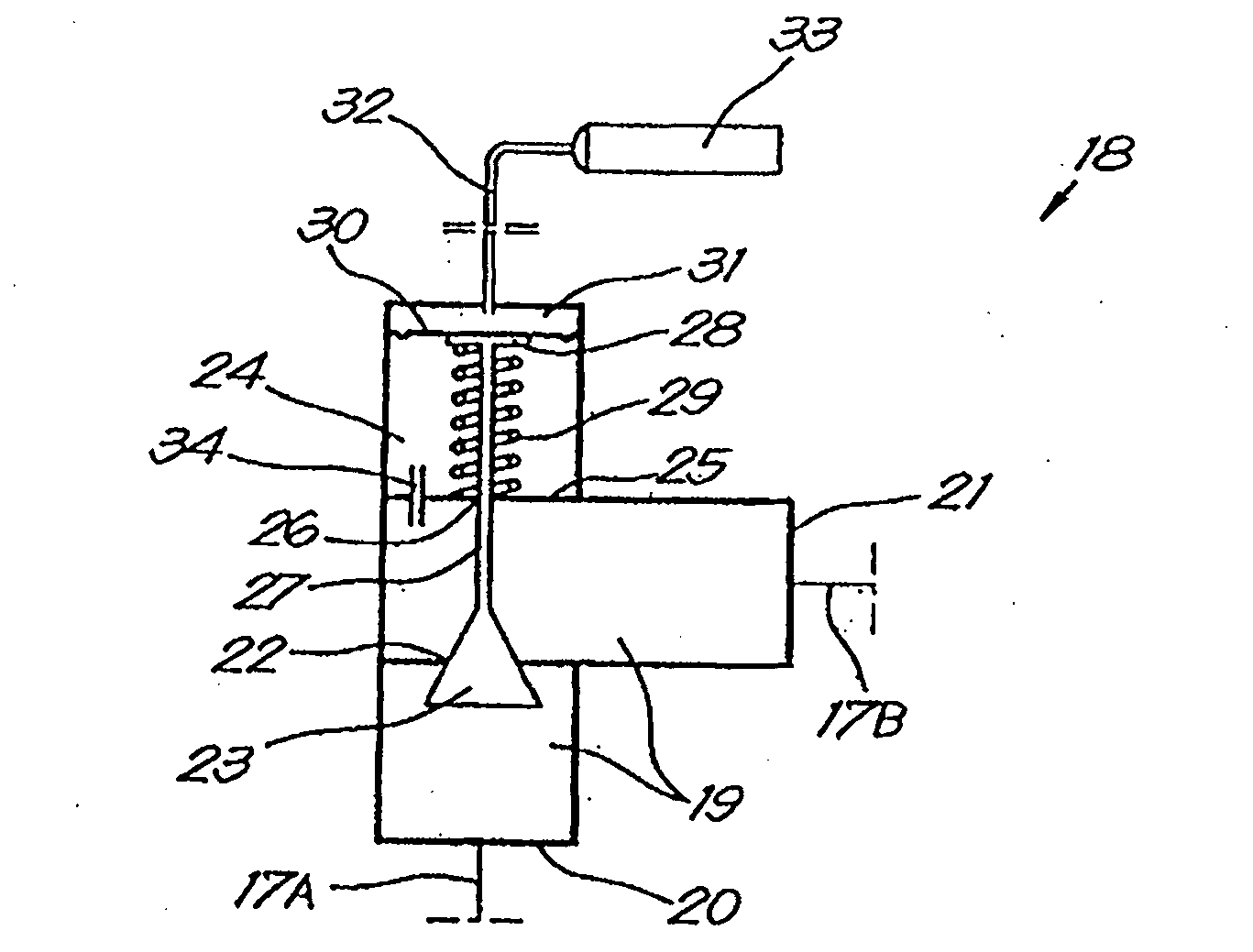

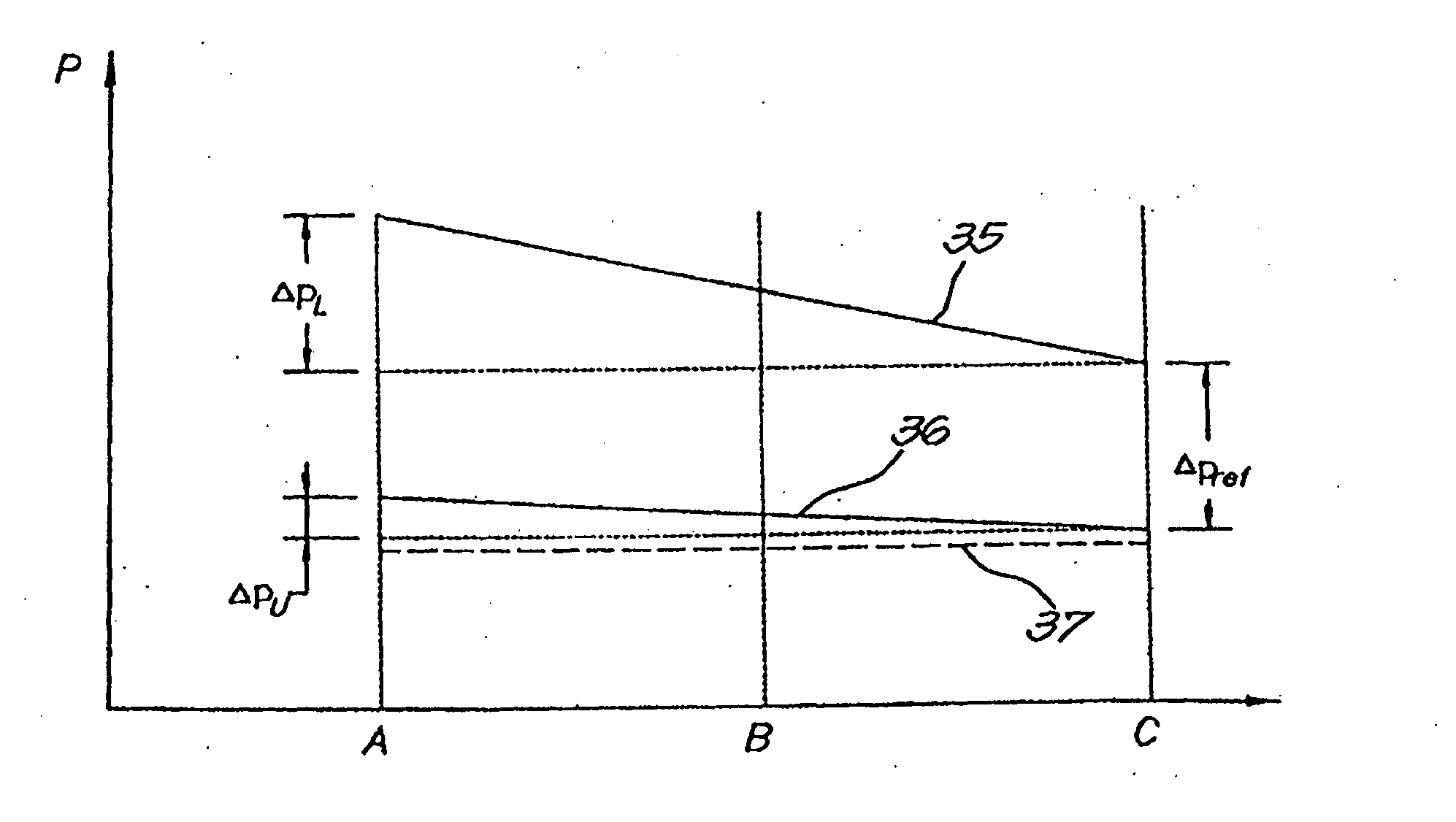

[0041]In addition, the cooling line 2 comprises successively in the coolant flow direction: a condenser 5, which is connected to the outlet of the compressor 3 and cooled, for example, by means of a fan 6; an expansion device 7, for example in the form of an expansion valve; an evaporator 8, It is connected to the inlet of the aforementioned compressor 3 and forms part of a heat exchanger 9 having a primary part formed by an evaporator 8 and intended to drive the gas to be dried through a supply duct 11 in the direction of arrow L in order to Secondary section cooled by evapor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com