Energy-harvesting conveyor belts and methods

A technology of conveyors and belts, applied in the direction of conveyors, conveyor objects, conveyor control devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

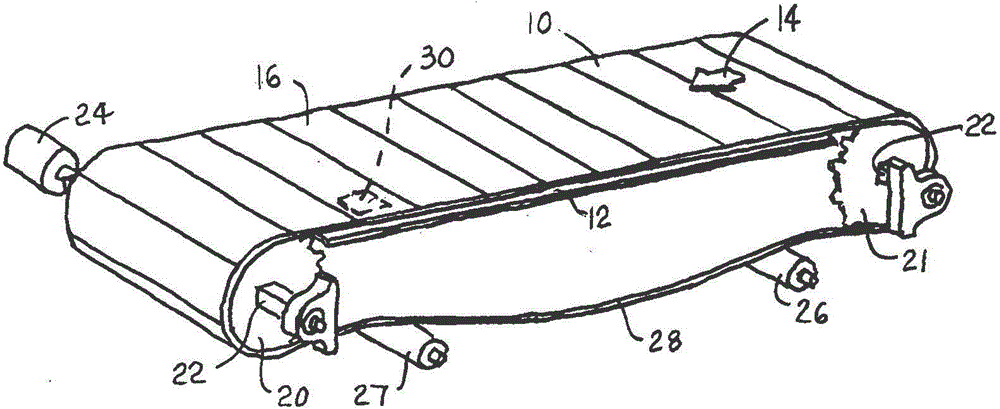

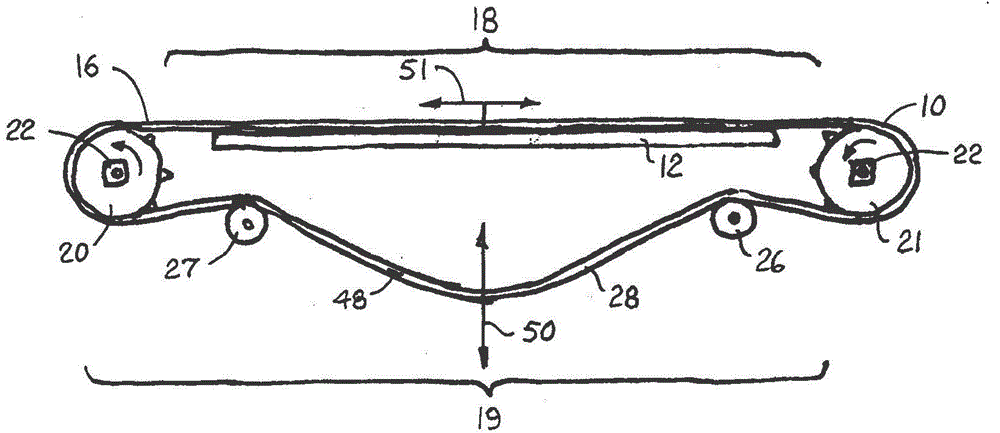

[0022] exist figure 1 and image 3 A version of a conveyor system incorporating features of the present invention is shown in . Conveyor (shown in this example as a conveyor belt 10 supported on a conveying path 12) along a conveying path segment 18 of the endless conveyor path of the belt on an outer conveying surface 16 in a conveying direction 14 on transport items. At the end of the conveyance path, items are conveyed off the conveyor belt. After bypassing the drive sprocket 20 , the conveyor belt 10 passes through a return section 19 on its way around the idler sprocket 21 back to the transport path section 18 . Both the drive sprocket and the idler sprocket are mounted on a rotatable shaft 22 . A drive motor 24 is coupled to the drive shaft in order to drive the belt in the conveying direction 14 . In the return path section 19 the belt is supported between a pair of spaced rollers 26, 27 or shoes so as to absorb sag in the catenary 28 formed between these rollers. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com