Forced-discharging and self-cleaning type centrifugal throwing machine

A technology of self-cleaning and drying machines, applied in centrifuges, centrifuges with rotating drums, etc., can solve problems such as blockage of filter holes, achieve the requirements of free from lubrication, convenient installation, and lower installation accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

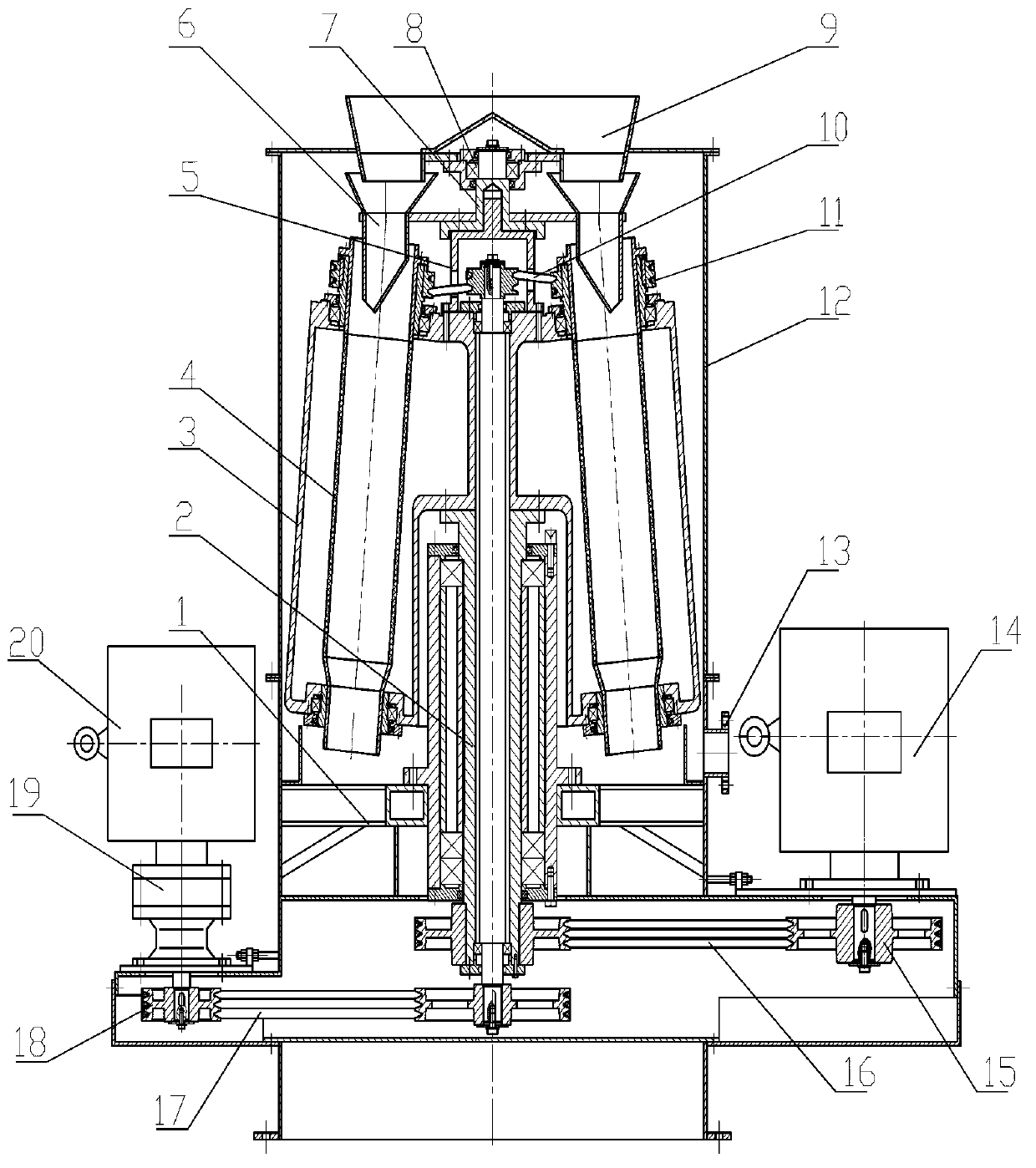

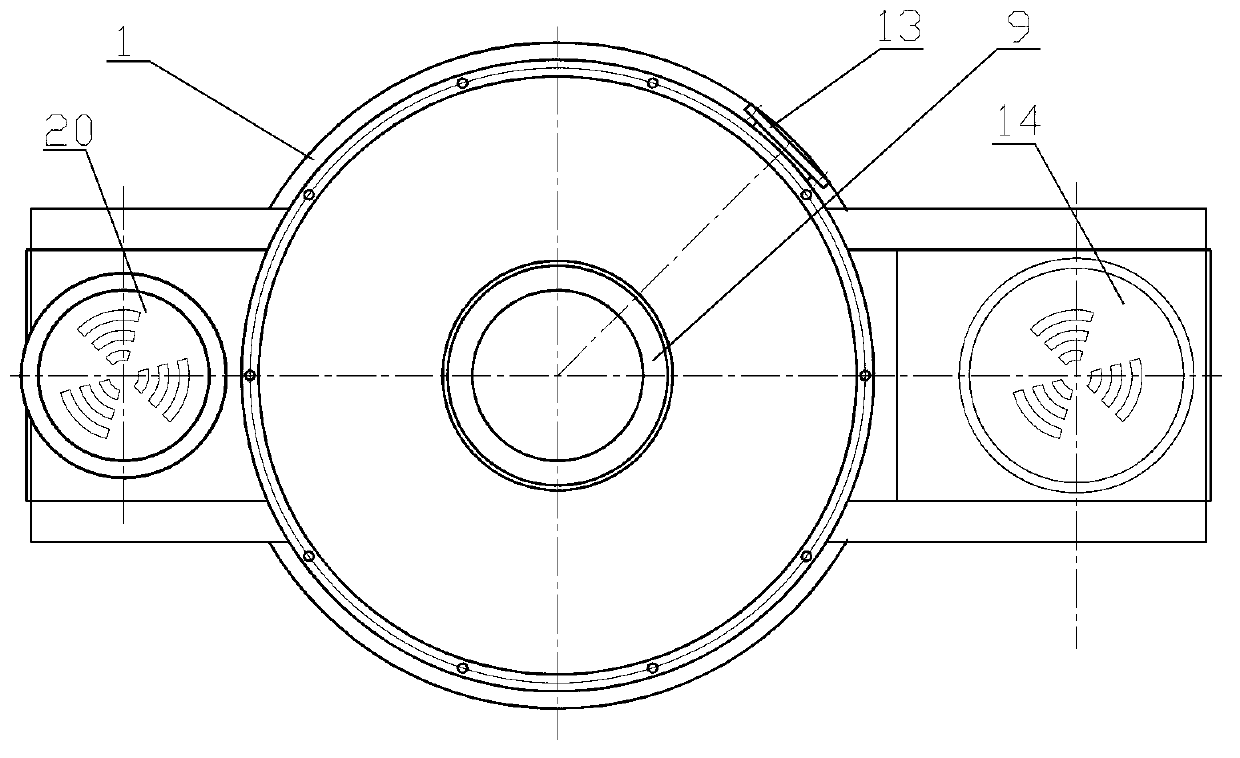

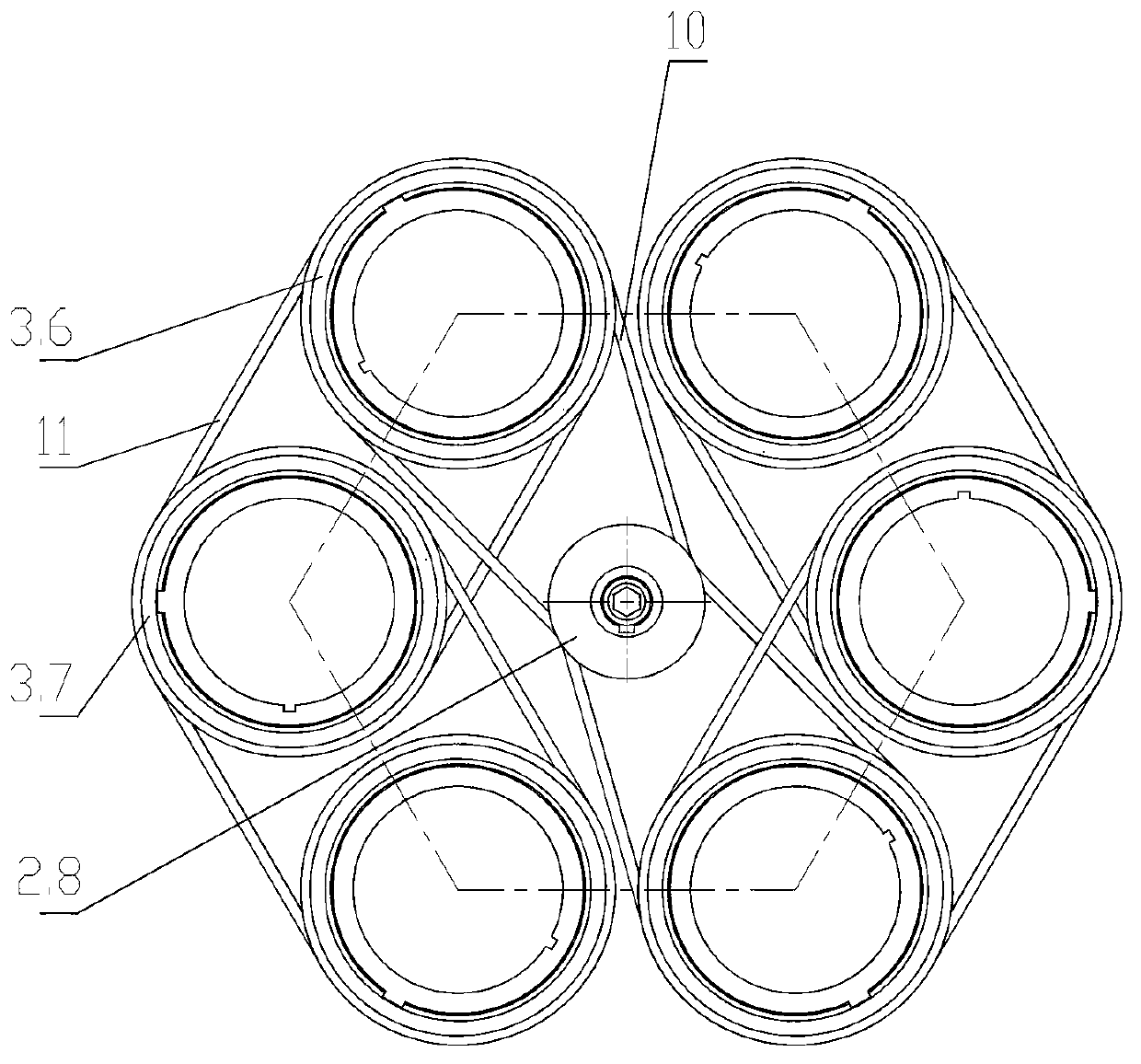

[0028] Below with reference to accompanying drawing, further describe:

[0029] According to the present invention, if Figure 1 to Figure 12 As shown, 1 is the skirt seat, 2 is the transmission assembly, 3 is the drum assembly, 4 is the filter cartridge, 5 is the connecting shaft, 6 is the dynamic feeding port, 7 is the end shaft, 8 is the auxiliary bearing, 9 is the static 10 is the linkage transmission belt, 11 is the transmission belt between cylinders, 12 is the shell, 13 is the discharge pipe, 14 is the revolution motor, 15 is the revolution main pulley, 16 is the revolution transmission belt, 17 is the rotation transmission Belt, 18 is the rotation main belt pulley, 19 is the speed reducer, 20 is the rotation motor, 3.6 is the filter cartridge pulley, 3.7 is the adjacent filter cartridge pulley, and 2.8 is the linkage pulley.

[0030] Such as Figure 1 to Figure 12In the self-cleaning centrifugal dryer shown, the lower end of the housing 12 is connected to the upper e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com