A hand-held glue injection booster device

A force-boosting device and hand-held technology, which is applied to devices and coatings that apply liquid to surfaces, and can solve problems such as safety accidents, limited operating space, and small air gap volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

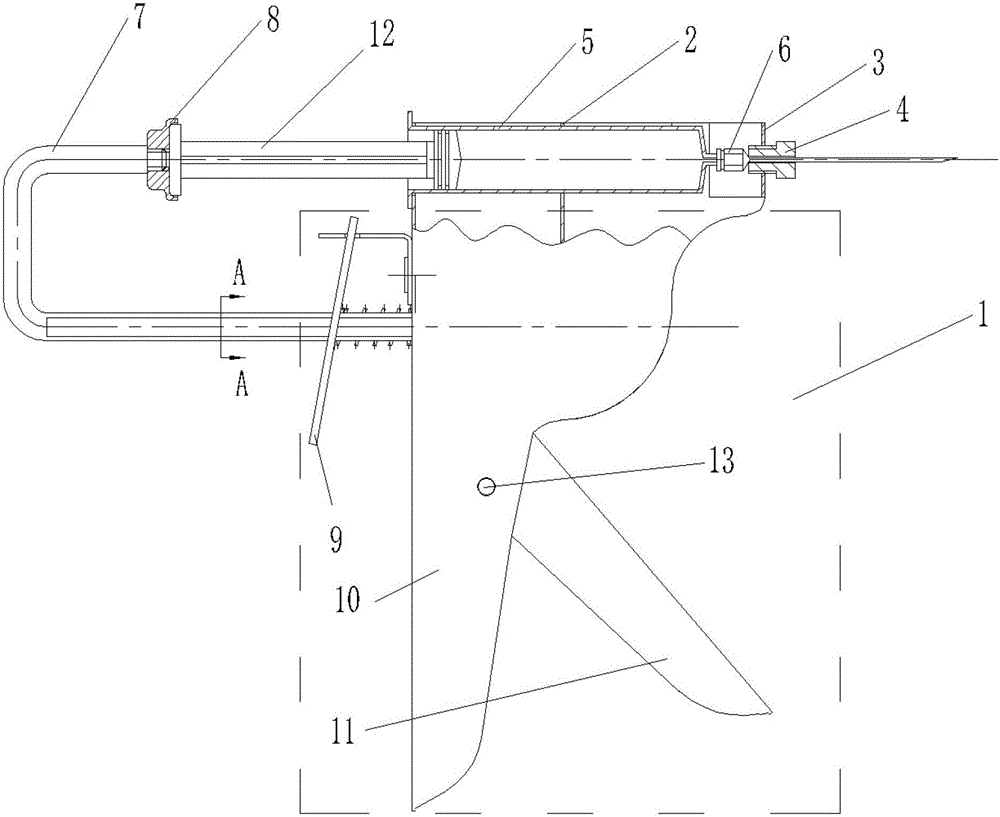

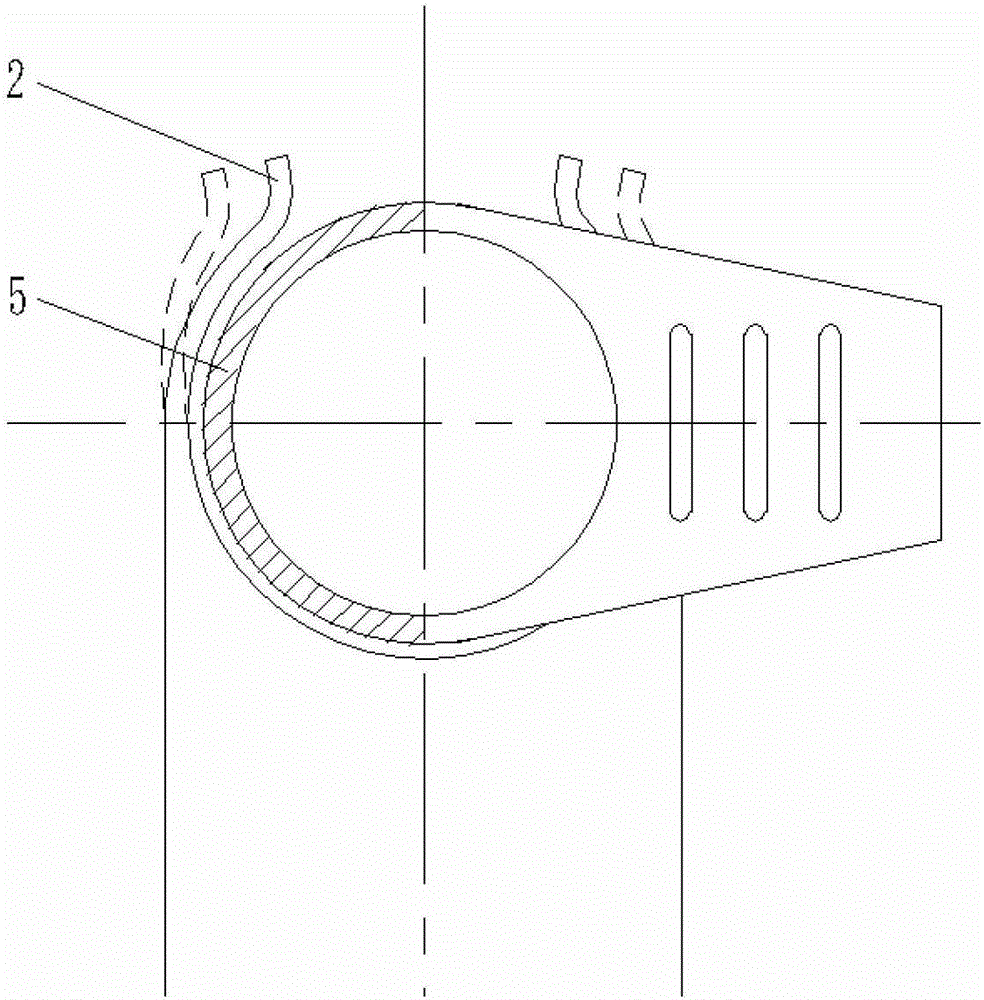

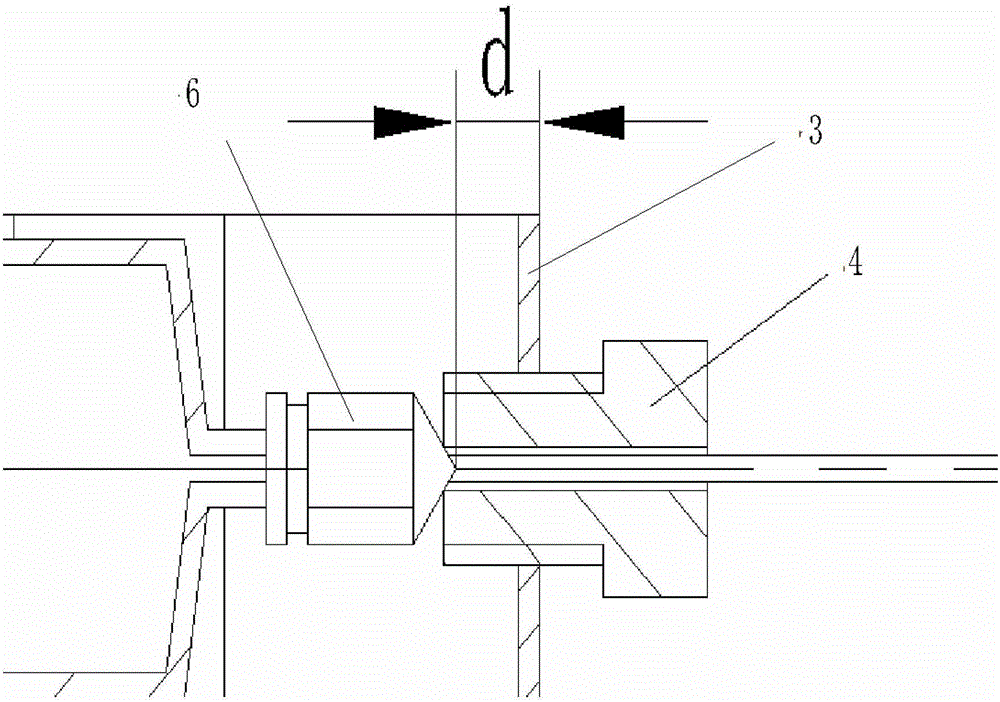

[0020] A kind of hand-held glue injection booster device of the present invention, as figure 1 As shown, the device mainly includes: booster mechanism 1, syringe bracket 2, baffle plate 3, thread ferrule 4, syringe 5, needle head 6, push rod 7, push piece 8, and thread ferrule 4 is the booster The power mechanism 1 adopts a traditional glass glue gun power-increasing mechanism, including a grip 10 and a trigger 11 connected with a pin 13, and an iron sheet 9 for unloading pressure. The syringe support 2 is located above the booster mechanism 1, and is made as a whole with the booster mechanism 1, such as figure 2 As shown, the syringe support 2 is a circular groove with an elastic closure on the top; the baffle 3 is located at the front end of the syringe support 2, and the two are welded together. There is a hole in the middle of the threaded ferrule 4, which is connected with the baffle 3 are screwed together, such as image 3 As shown; the syringe 5 is located inside the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com