Device and method for uploading solder paste to metal honeycomb carrier

A metal honeycomb carrier and solder paste technology, which is applied to auxiliary devices, metal processing equipment, welding equipment, etc., can solve the problems that the metal honeycomb carrier cannot meet the requirements of high efficiency and energy saving, and achieves a simple and feasible method, saving solder and reasonable resources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

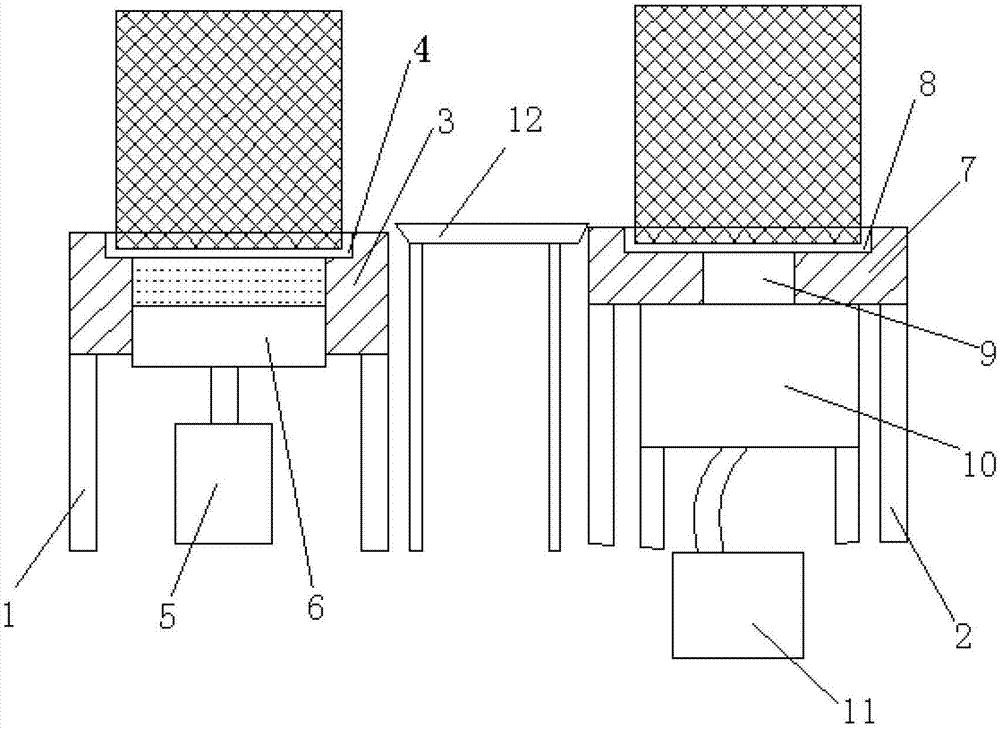

[0021] Referring to the accompanying drawings, a solder paste uploading device for a metal honeycomb carrier includes a pneumatic propulsion device 1 for solder paste and a negative pressure recovery device 2 for solder paste. The pneumatic propulsion device 1 for solder paste includes a first bracket, The storage mold 3 is mounted on the first support, and the storage mold 3 is provided with a step hole 4. The aperture of the step hole 4 is large and small, and the bottom of the storage mold 3 is provided with a cylinder 5, and the piston rod extension end of the cylinder 5 Vertically upward, and the protruding end is fixed with a piston 6 that matches the diameter of the lower hole of the stepped hole 4. The upper hole of the stepped hole 4 is used to fix the metal honeycomb carrier, and the piston cylinder structure is formed between the lower hole and the matched piston 6. , and the solder paste is placed in the cavity of the piston cylinder structure, and the piston 6 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com