Multi-axis machining center structure

A technology of multi-axis processing and center structure, which is applied in metal processing, metal processing equipment, metal processing machinery parts, etc., can solve the problems of long auxiliary time, low processing efficiency, and long time consumption, and achieve low processing efficiency and fast response speed , The effect of shortening the processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

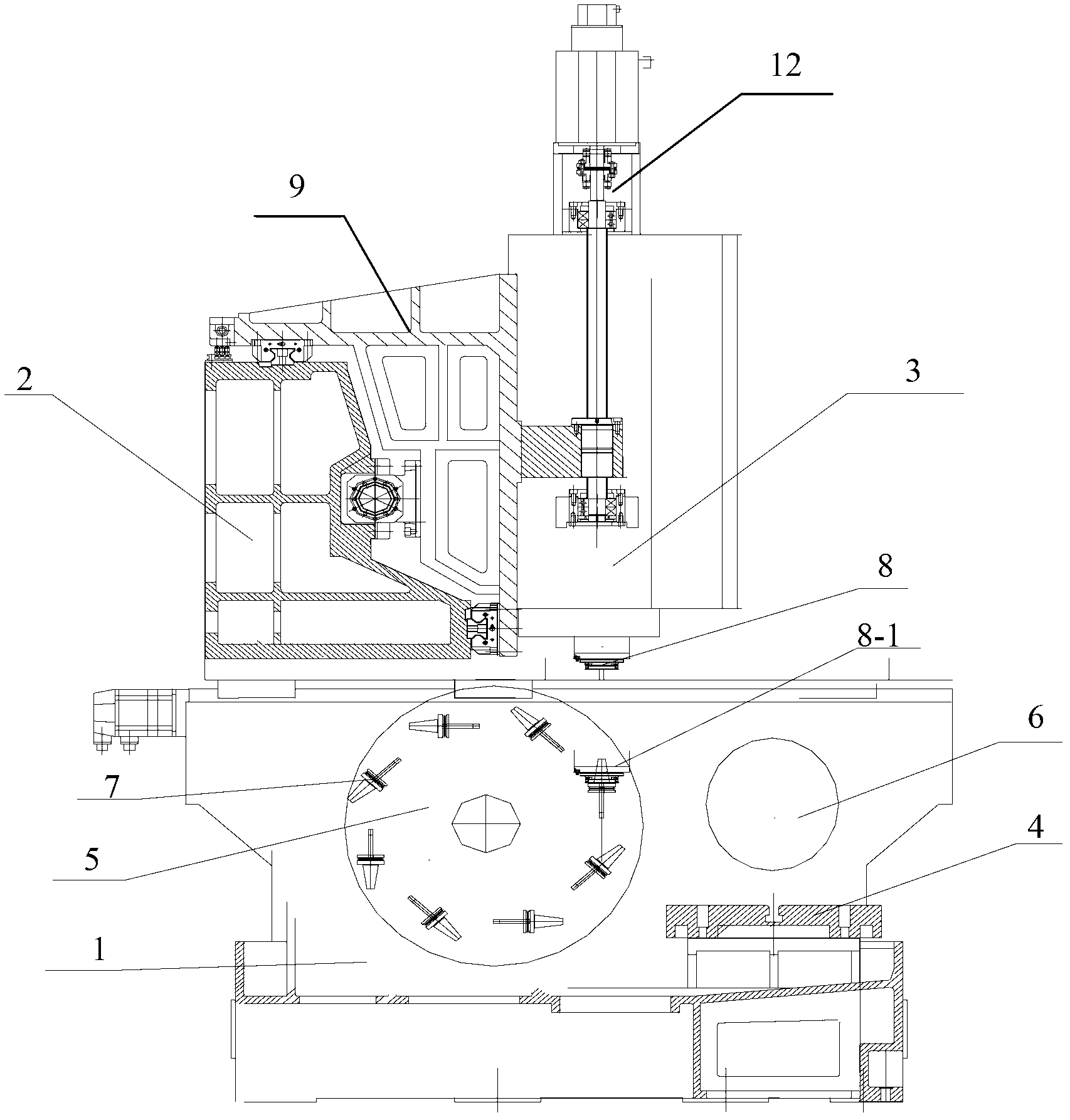

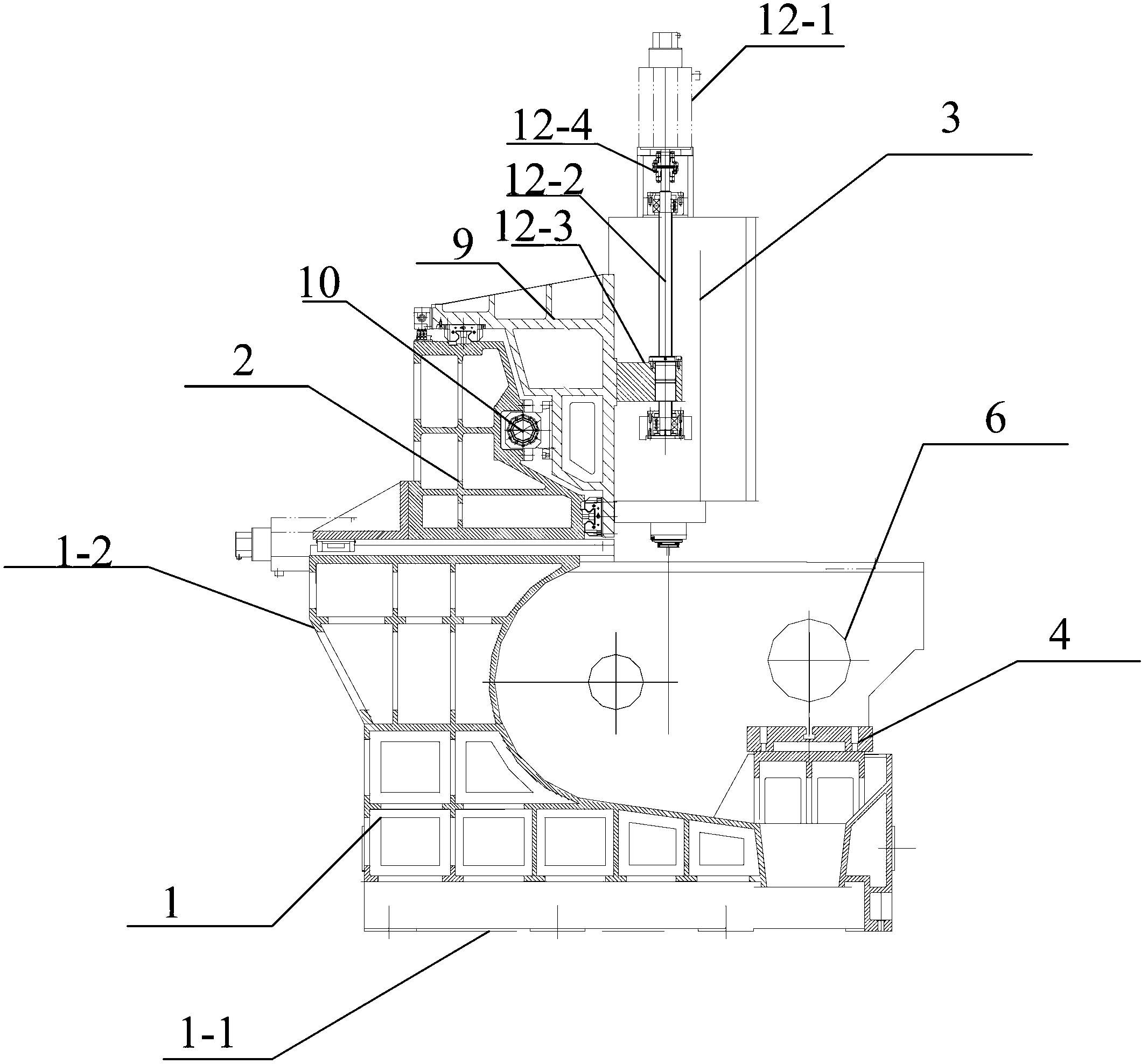

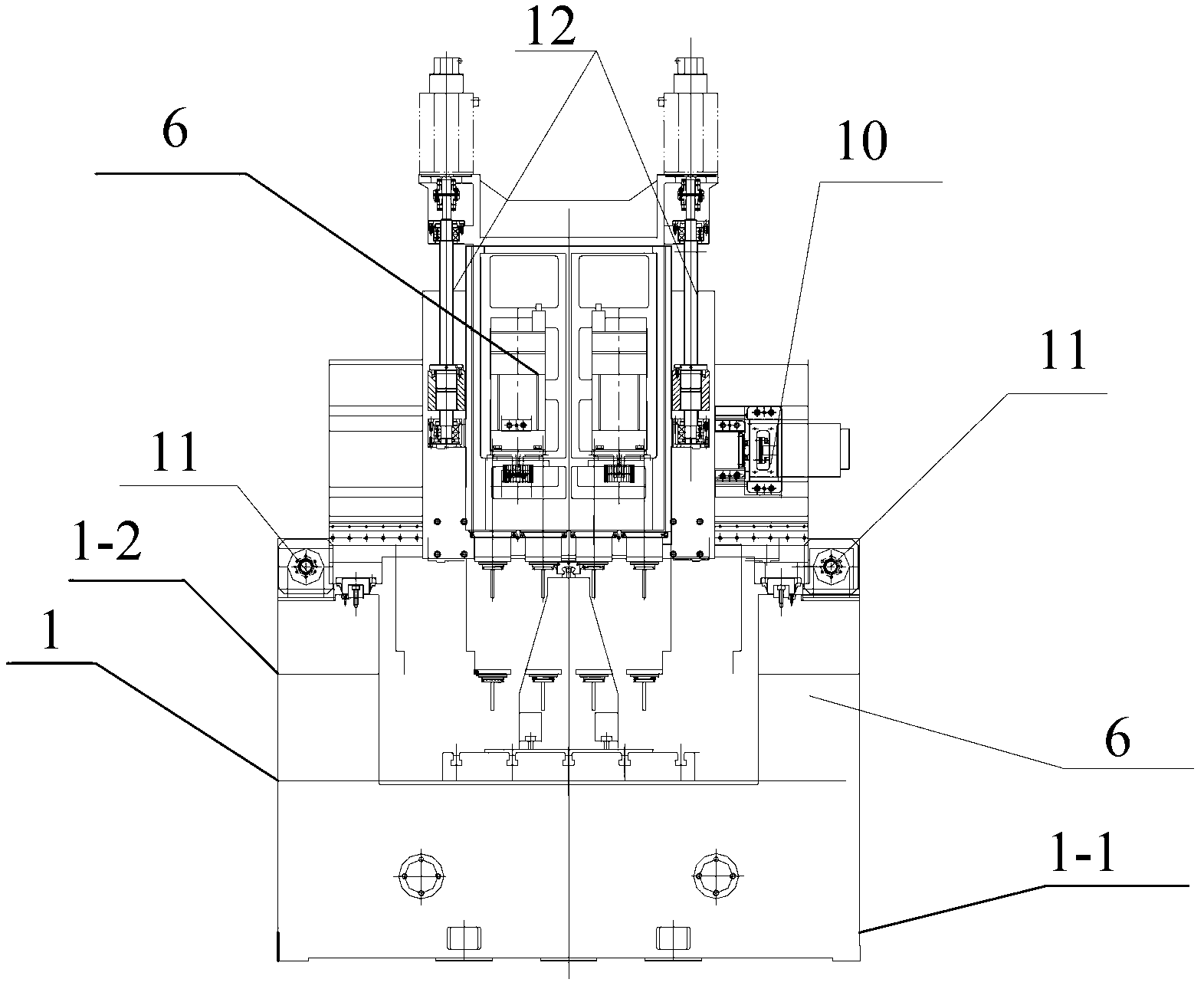

[0040] Such as Figures 1 to 6 As shown, a machine tool with a vertical multi-axis machining center structure includes an integral bed 1, two beams 2, a saddle 9, a multi-axis headstock 3, a first transmission mechanism 11, a second transmission mechanism 10 and a third transmission mechanism 12,

[0041] The one-piece bed includes a base 1-1 and two side walls 1-2, and the base 1-1 is provided with a

[0042] The one-piece bed includes a base 1-1 and two side walls 1-2, and the base 1-1 is provided with a detachable fixed worktable 4;

[0043] The two beams 2 are respectively installed on the two side walls 1-2; the saddle 9 is fixed on the inner side of one of the beams 1-2; the first transmission mechanism 11 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com