Multi-working-face contact network work vehicle

A multi-working surface, catenary technology, applied in motor vehicles, goods transport vehicles, vehicles used for freight, etc., can solve the problems of long occupancy of skylights, low work efficiency, affecting railway transportation efficiency, etc., to improve work efficiency. , the effect of saving skylight time and wide field of vision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

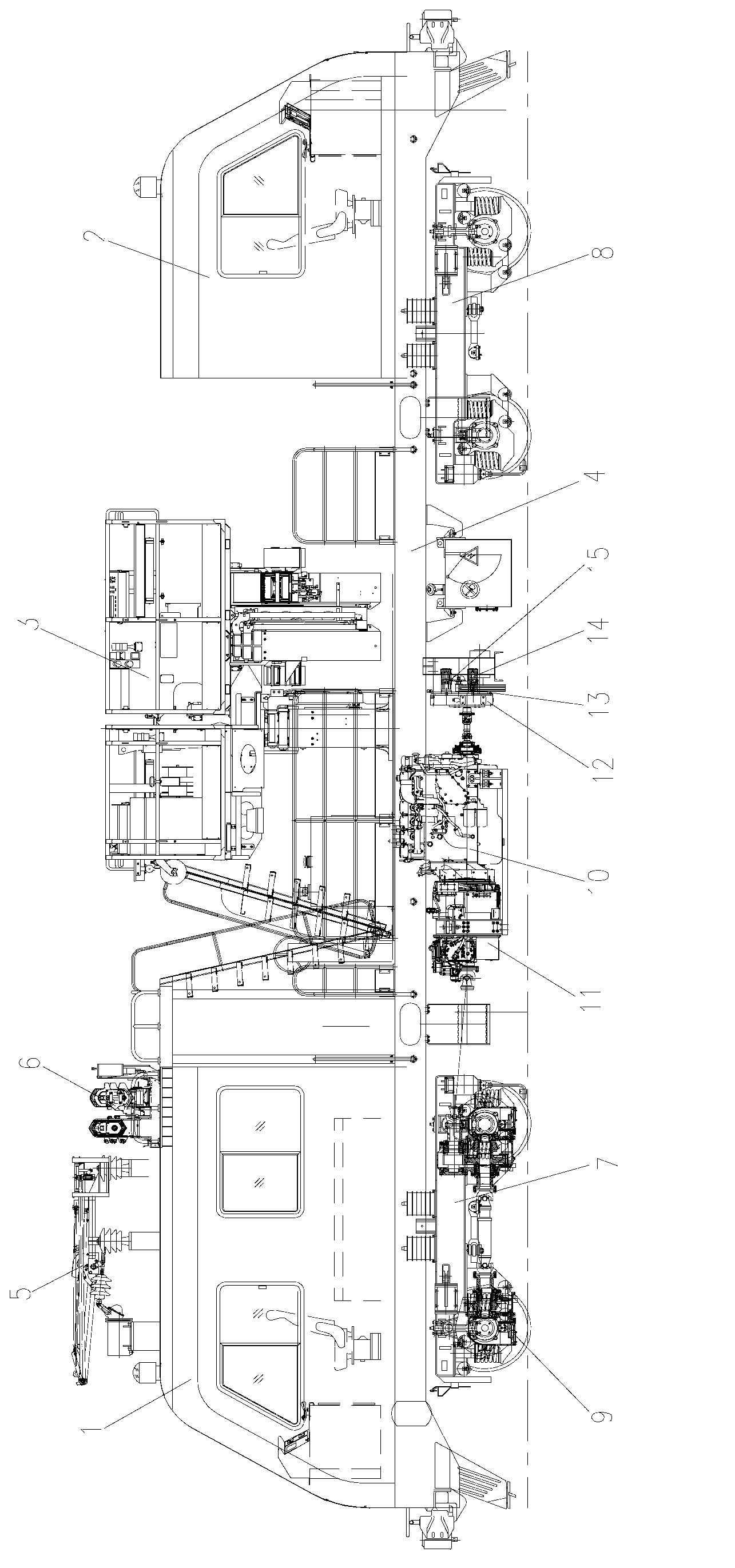

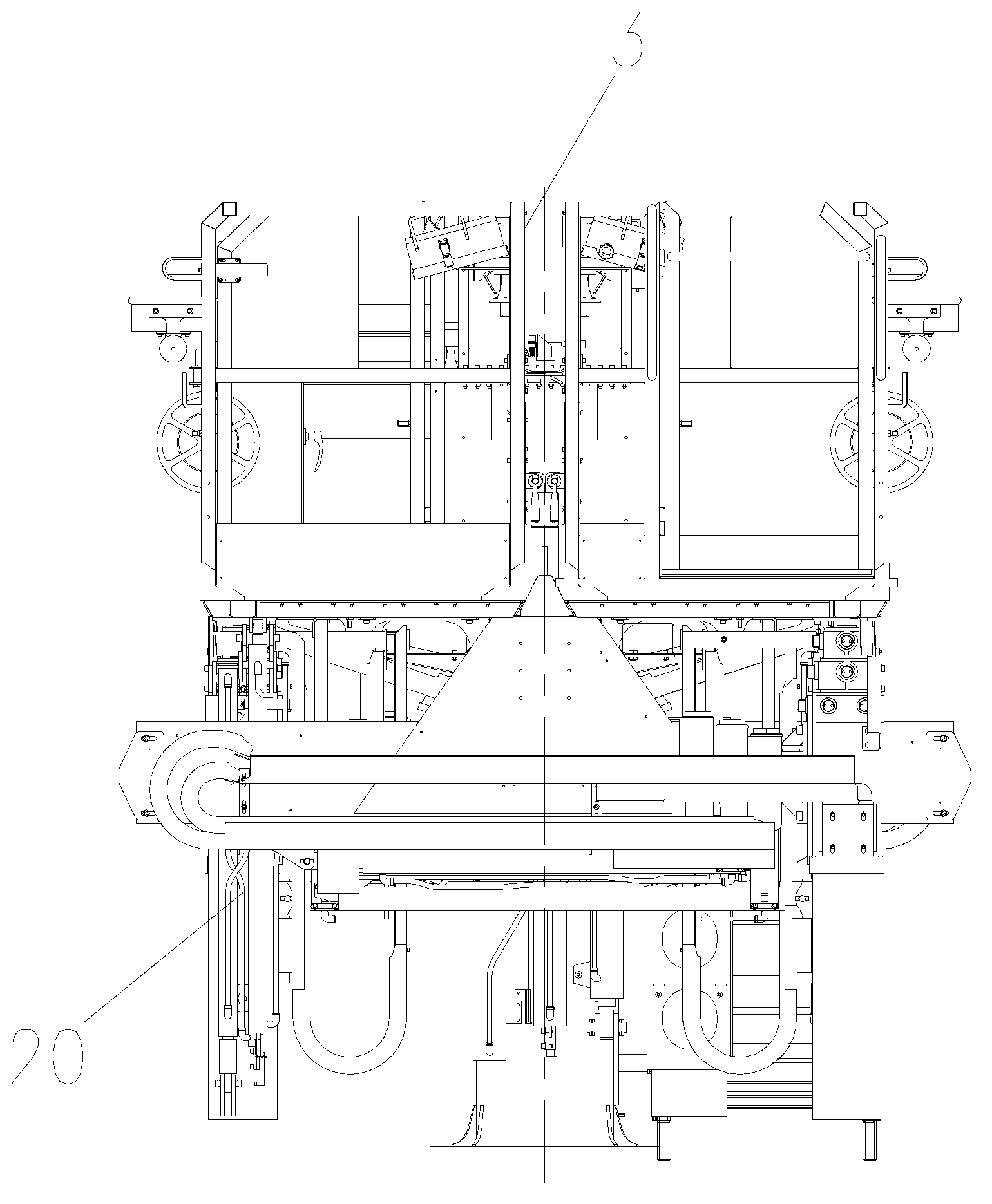

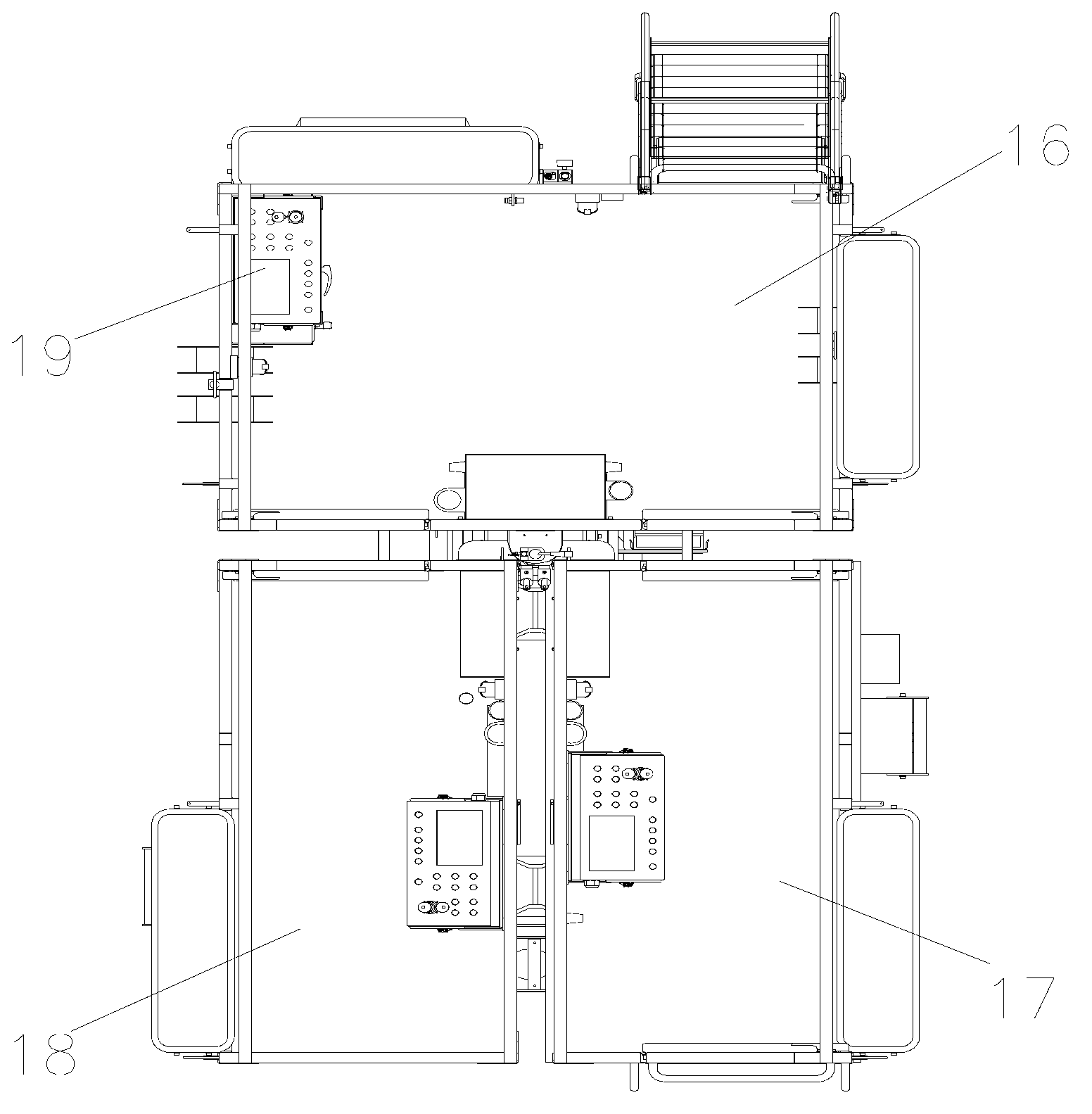

[0016] Attached below Figure 1-4 An embodiment of the present invention is described.

[0017] The multi-face catenary operation vehicle has a vehicle frame 4, and the upper end of the vehicle frame 4 is provided with a vehicle body I1 and a vehicle body II2. Both the vehicle body I1 and the vehicle body II2 are provided with a cab. It is equipped with driver's station, electrical control system, sleeping berth, air conditioner, driver's seat and fire extinguisher. A three-platform operating mechanism 3 that moves vertically and left and right is provided between the car body I1 and the car body II2, and a pantograph-catenary detection device 5 and a wire lifting device 6 are provided on the car body I1. The car body I1 and the car body II 2 is located at both ends of the vehicle frame 4, and the three-platform operating mechanism 3 is located in the middle of the vehicle frame 4, so that the vehicle has a good field of vision when driving in reverse. Specifically, the thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com