A new type of vibration-absorbing and isolating support and its replacement method

A replacement method and a technology for vibration reduction and isolation, which can be used in earthquake resistance, building components, buildings, etc., and can solve problems such as high cost, difficult jacking, and affecting the safe use of bridges or buildings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

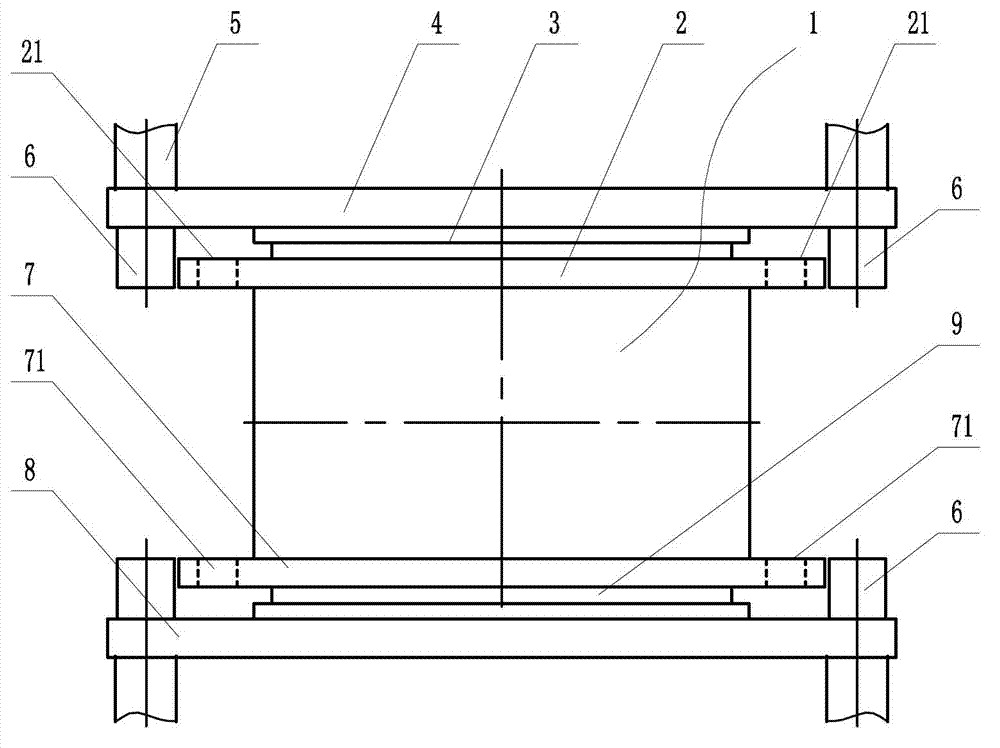

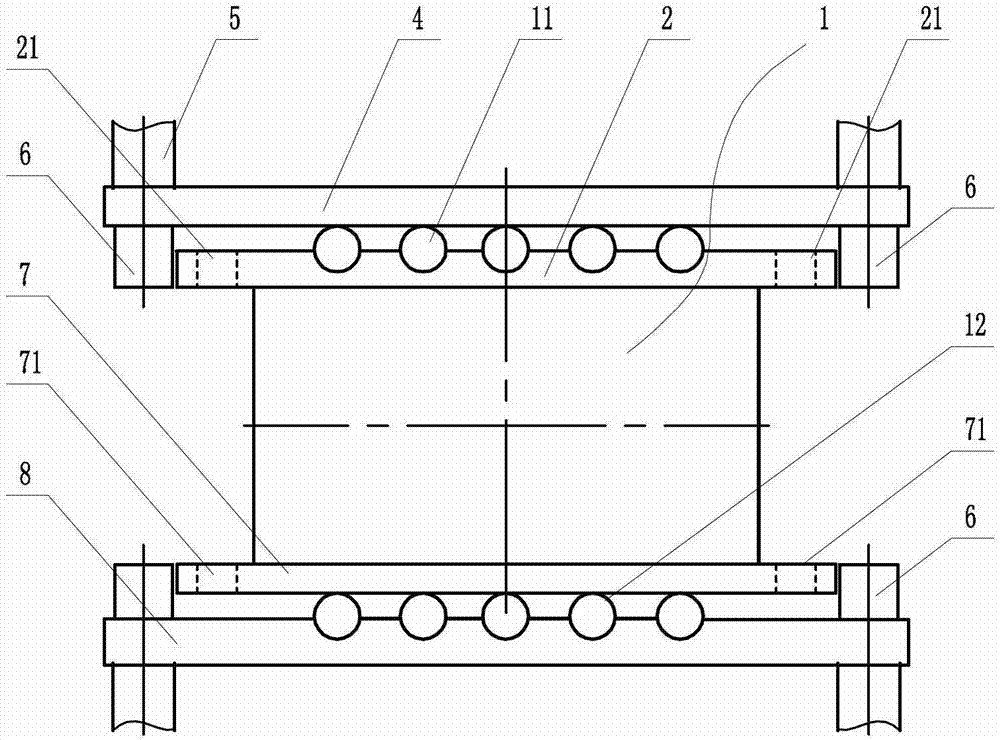

[0033] one A new type of shock-absorbing and isolating bearing, comprising a bearing body 1, said bearing body including a bearing core formed by overlapping a rubber layer and a stiffened steel plate layer, and an upper steel plate 2 and a lower steel plate connected to the upper / lower end surface of the bearing core 7,

[0034] The shock-absorbing and isolating support also includes an upper connecting steel plate 4 and a lower connecting steel plate 8 located at the upper / lower part of the bearing body, the upper side of the upper connecting steel plate is provided with a sleeve and anchor bolts 5, and the lower side of the upper connecting steel plate is There is a limit stopper 6 used to limit the horizontal sliding of the support body; the lower side of the lower connecting steel plate is provided with a sleeve and anchor bolts 5, and the upper side of the lower connecting steel plate is provided for limiting the horizontal sliding of the supporting body. The limit bloc...

Embodiment 2

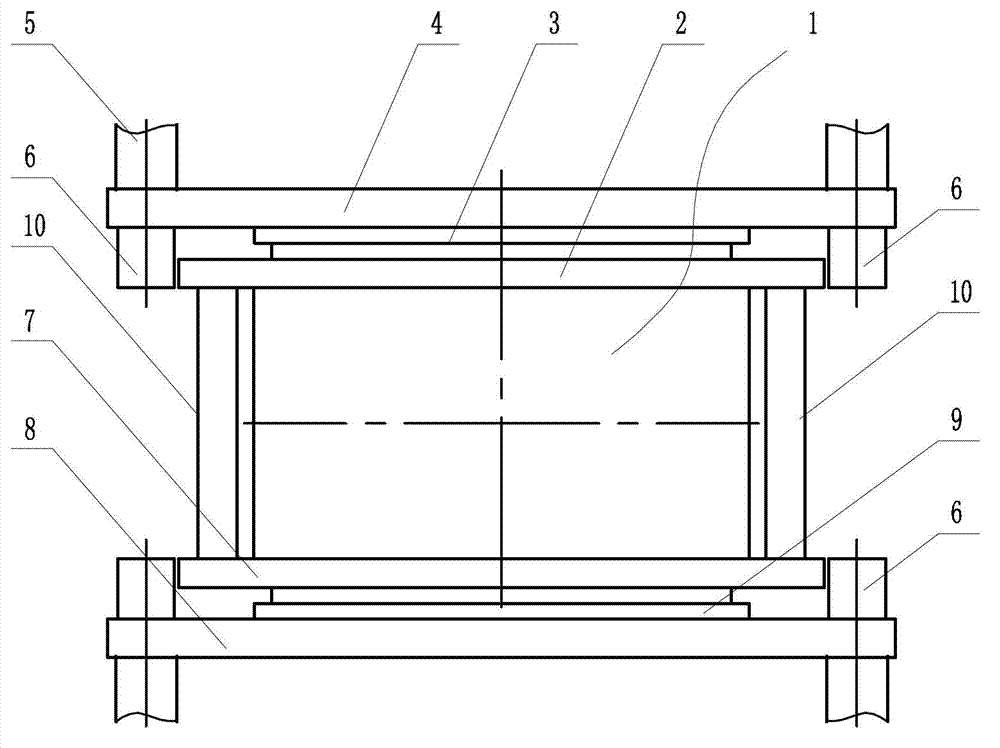

[0040] one A new type of shock-absorbing and isolating support, its basic structure is the same as that of Embodiment 1, including a support body 1, and the support body includes a support core formed by overlapping a rubber layer and a stiffened steel plate layer and is connected on the support core / The upper steel plate 2 and the lower steel plate 7 of the lower end face,

[0041] The shock-absorbing and isolating support also includes an upper connecting steel plate 4 and a lower connecting steel plate 8 located at the upper / lower part of the bearing body, the upper side of the upper connecting steel plate is provided with a sleeve and anchor bolts 5, and the lower side of the upper connecting steel plate is There is a limit stopper 6 used to limit the horizontal sliding of the support body; the lower side of the lower connecting steel plate is provided with a sleeve and anchor bolts 5, and the upper side of the lower connecting steel plate is provided for limiting the hor...

Embodiment 3

[0048] Embodiment 1 A replacement method of a novel shock-absorbing and isolating bearing, comprising the following steps:

[0049] 1) According to the uncompressed height of the support to be replaced, that is, the design height H0 between the upper steel plate and the lower steel plate of the support body, select a new type of shock-absorbing and isolating support with the same design height. The secondary surface of the sliding friction pair on the upper steel plate and the lower steel plate of the support body is spare;

[0050] 2) Distribute n measuring points evenly around the periphery of the support to be replaced and take the average height, measure the height H1 between the upper steel plate and the lower steel plate of the support body when the support body to be replaced bears the structural weight, n is 2~ Any integer between 32;

[0051] 3) Put the spare support on the press for compression, so that the height between the upper steel plate and the lower steel pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com