Laminate type high-rise platform pile tower crane foundation and construction method

A high-pile cap tower and tower crane foundation technology, which is applied in the field of tower crane foundation, can solve the problems of increasing the amount of welding work for steel structures, increasing the welding process, and limiting the use time of tower cranes, so as to shorten the construction period of the foundation pit and shorten the excavation time , The effect of simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to facilitate the understanding of the structure of the present invention, the following description will be made in conjunction with the accompanying drawings and embodiments.

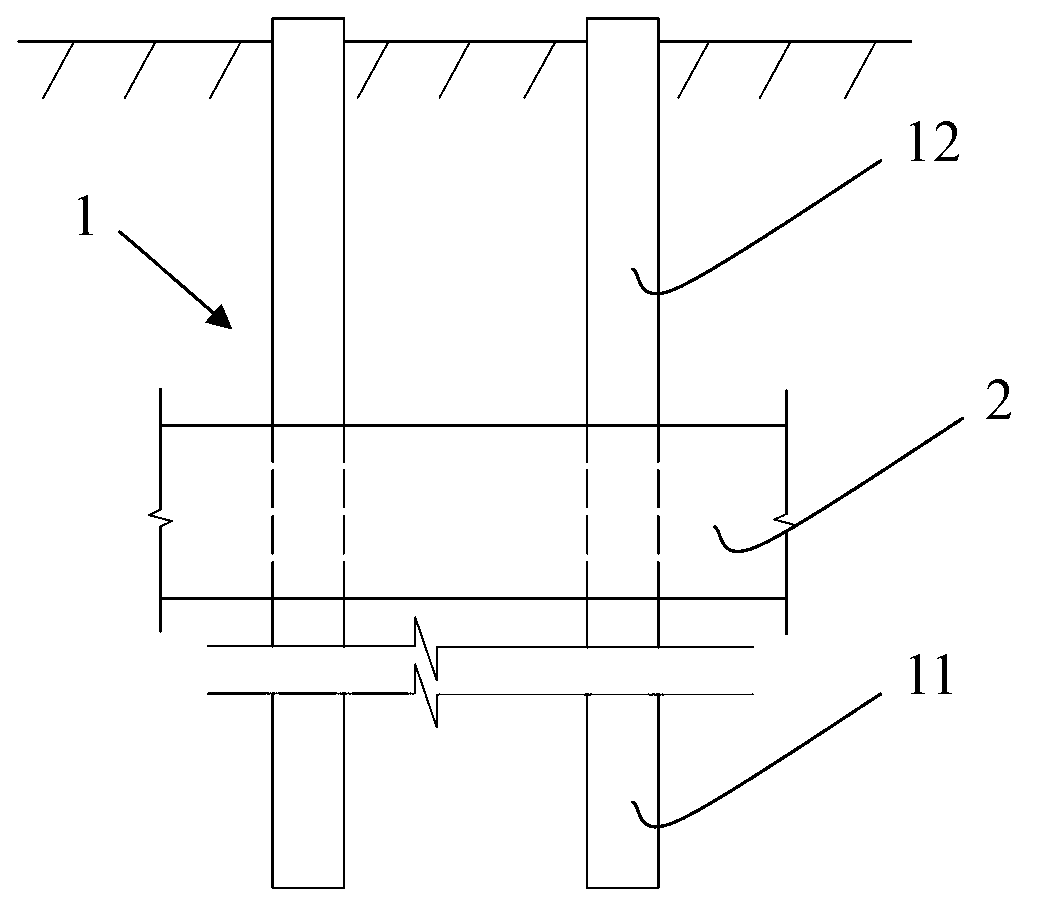

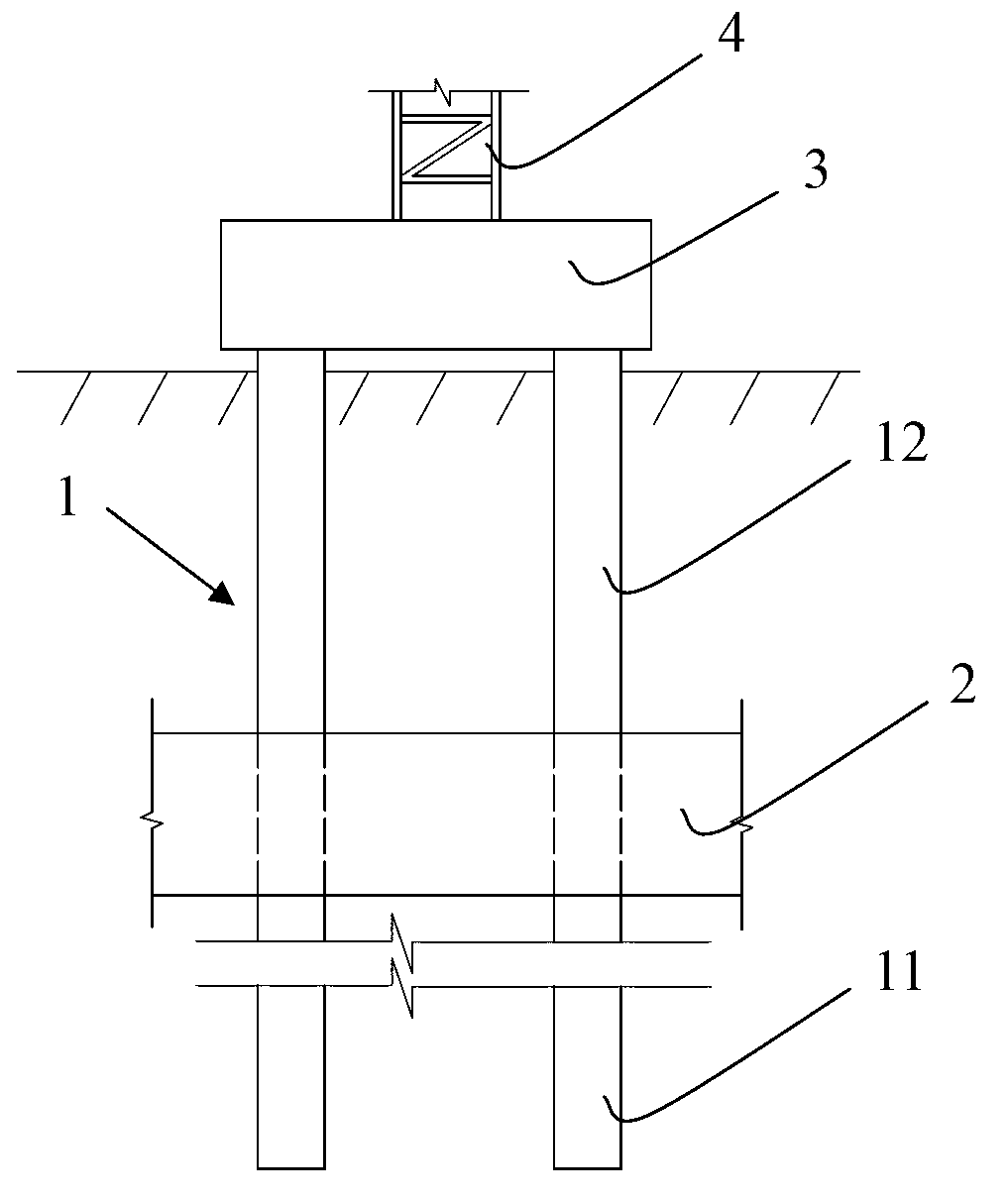

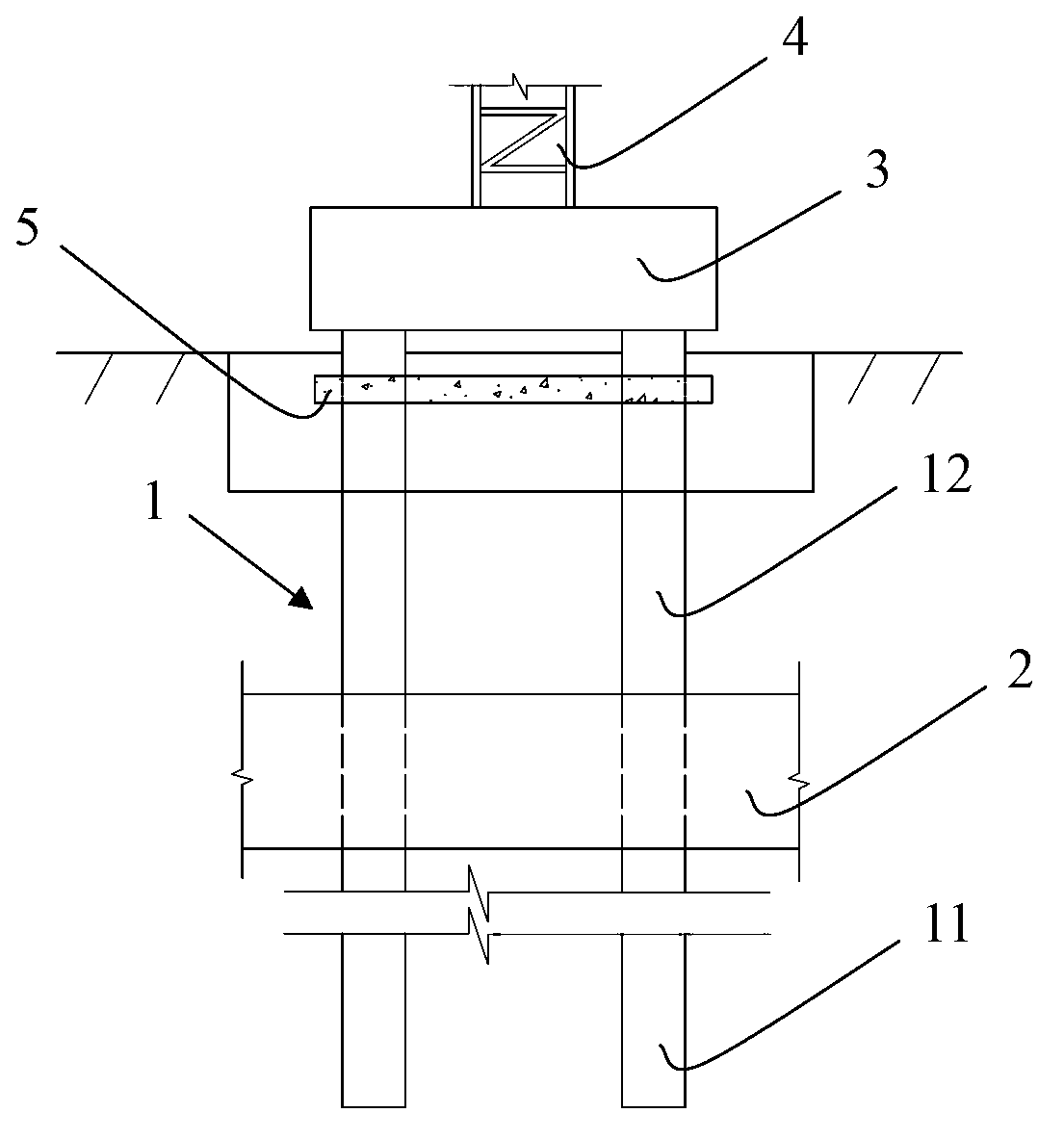

[0021] combine Figure 4 and Figure 5 As shown, the floor plate type high pile cap tower crane foundation structure of the present invention includes four concrete cast-in-place piles 1 arranged in the foundation pit, arranged in a square, the pile top elevation is located near the ground surface, and the cast-in-place piles 1 are penetrated into the foundation floor 2 Inside, the ratio of the length of each cast-in-place pile 1 below the foundation floor 2 to the length of the anchor section 11 exposed in the foundation pit is not less than 2, ensuring the stability of the cast-in-place pile 1, and a reinforced concrete Cap 3, a tower crane foundation section 4 is pre-embedded in the concrete cap 3, and the tower body and the foundation structure can be fixedly integrated through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com