Steel pipe column-H-shaped beam joint adopting shape memory alloy bolts

A technology of memory alloy and steel pipe column, which is applied in the direction of construction and building construction, can solve the problems of shape memory alloy parts that no one has set foot in, and achieve the effects of convenient and fast installation and repair, small residual deformation, and enhanced intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

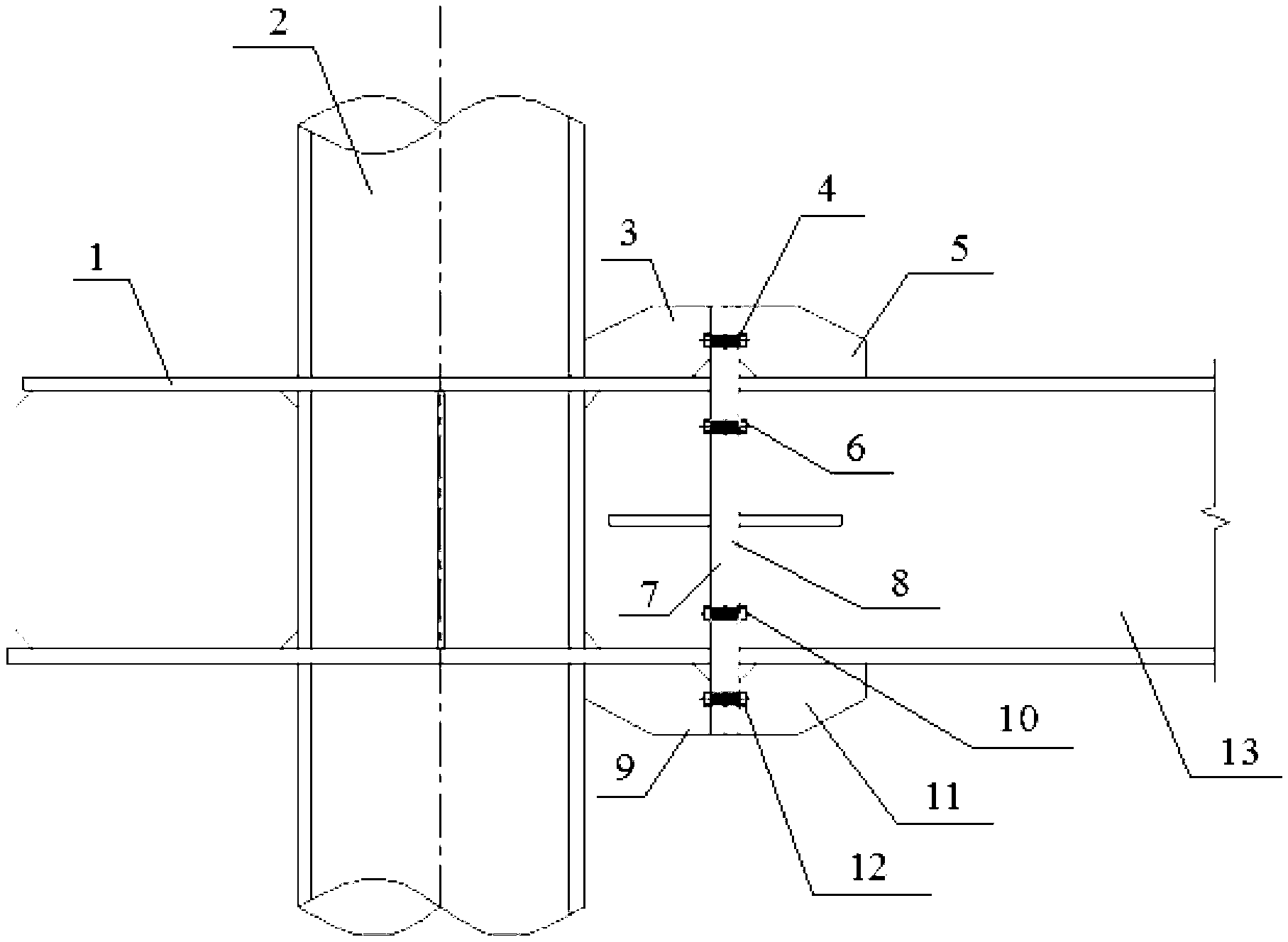

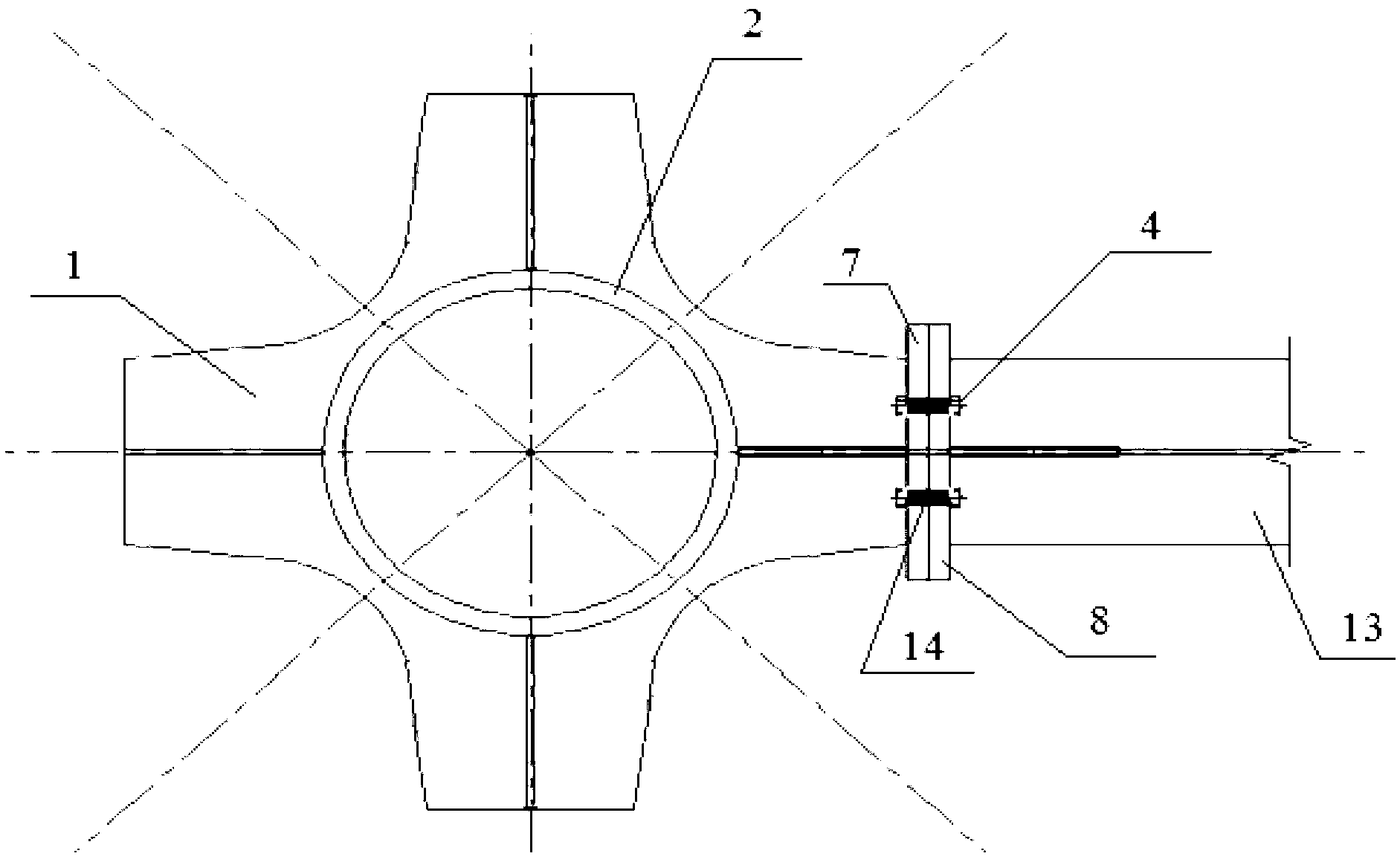

[0022] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

[0023] In order to overcome the deficiencies of the prior art, the present invention applies the large-size shape memory alloy component to the steel pipe column-H-shaped beam in the steel frame structure in consideration of the ductility, energy consumption and rigidity requirements of the circular tubular column-H-shaped beam joint connection, forming a circular tube column-H-shaped beam connection node with self-recovery and energy dissipation capabilities, figure 1 shown in its front view, figure 2 It is shown in top view.

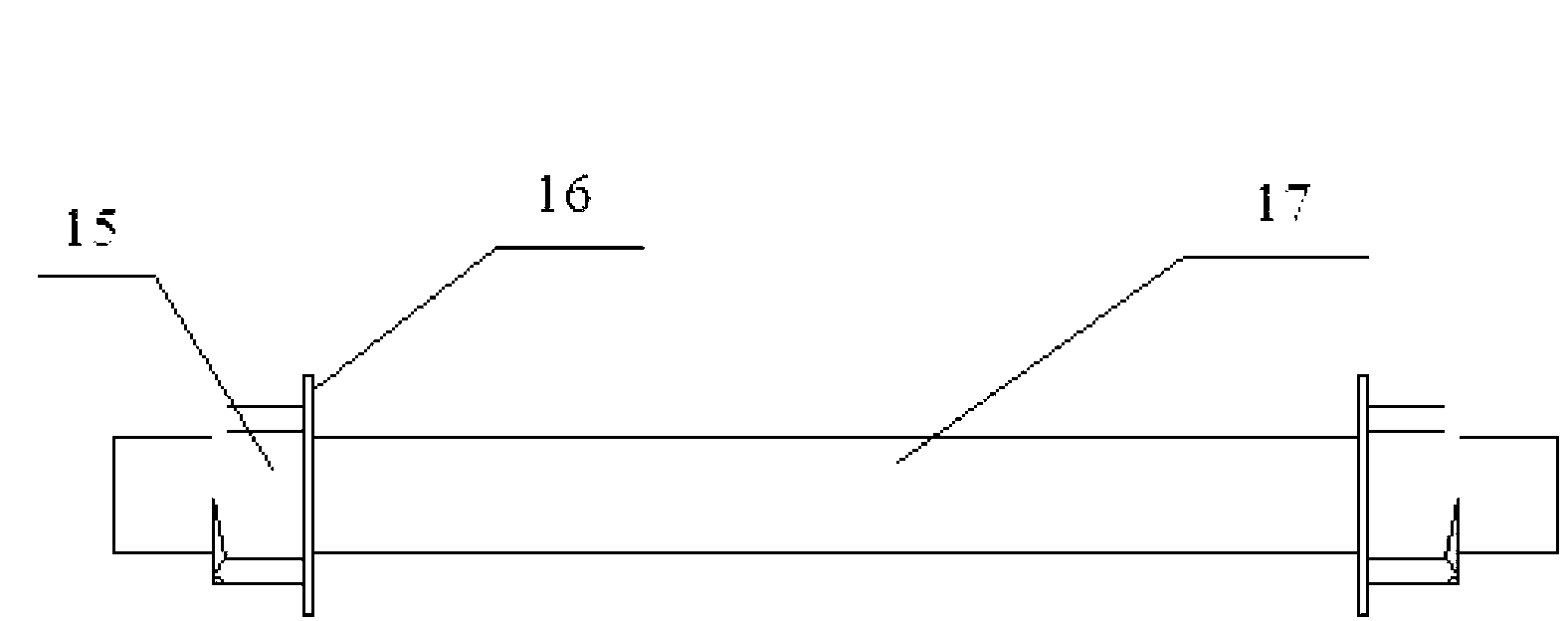

[0024] The steel pipe column-H-beam joint containing shape memory alloy bolts in the present invention includes column end components, beam end components, column connection end plates 7, beam connection end plates 8 and shape memory alloy bolts. Among them, the column end assembly is an assembly that includes the pi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com