Section bar for quickly modeling by using circular vertical column and polygonal vertical column and method for modeling by using section bar

A polygonal and profile technology, which is applied in the fields of formwork/template/work frame, on-site preparation of building components, construction, etc., can solve the problem of circular column modeling that is not suitable for small size, unfavorable for forest environmental protection, time-consuming and labor-intensive. labor and other problems, to reduce the use of wood, be conducive to protection, and save materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

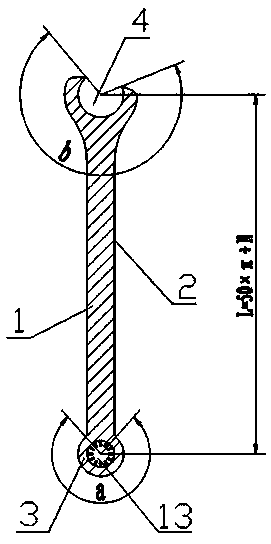

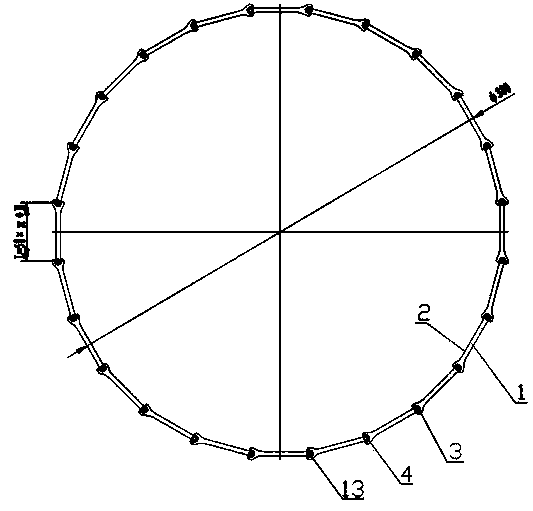

[0036] exist figure 1 In the shown embodiment, a profile for rapid modeling of a round column and a polygonal column includes a profile body 1. The profile body 1 can be made of recyclable materials such as aluminum alloy or engineering plastics or wood-plastic composite materials. The front of the main body 1 is a working surface 2, and the cavity for modeling is poured with slurry, and the working surface 2 of the profile main body 1 is a plane. Both sides of the profile body 1 are provided with coupling splices, the coupling splices include arc columns 3 and arc grooves 4, the arc columns 3 and arc grooves 4 are respectively arranged along the length direction of the profile body 1, and the arc columns 3 The arc angle a is greater than 180 degrees, the arc angle b of the arc groove 4 is greater than 180 degrees and less than the arc angle of the arc column 3, that is to say the opening size of the arc groove 4 is smaller than the diameter of the arc groove 4, ensuring Afte...

Embodiment 2

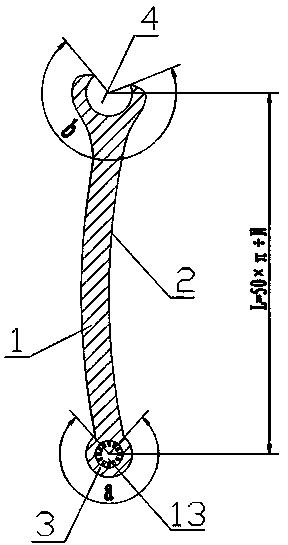

[0039] exist figure 2 In the shown embodiment, a profile for rapid modeling of a circular column and a polygonal column includes a profile body 1, and the structure of the profile body 1 is basically the same as that in Embodiment 1, the difference being: the work of the profile body 1 Surface 2 is a concave arc surface.

Embodiment 3

[0041] exist Figure 5 In the shown embodiment, a profile for rapid modeling of a circular column and a polygonal column includes a profile body 1, and the structure of the profile body 1 is basically the same as that in Embodiment 1, except that the back of the profile body 1 At least one T-shaped slot 9 is provided along the length direction of the profile body 1 , and a cavity 10 is also provided inside the profile body 1 along the length direction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com