Method for installing concrete light board wall and jacking and fixing device

A technology for concrete and slab walls, which is applied in the processing of walls, building materials, and building components. It can solve problems affecting the integrity of slab walls and sound insulation effects, and facilitate the laying of pipe networks, increase overall strength, and ensure construction quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

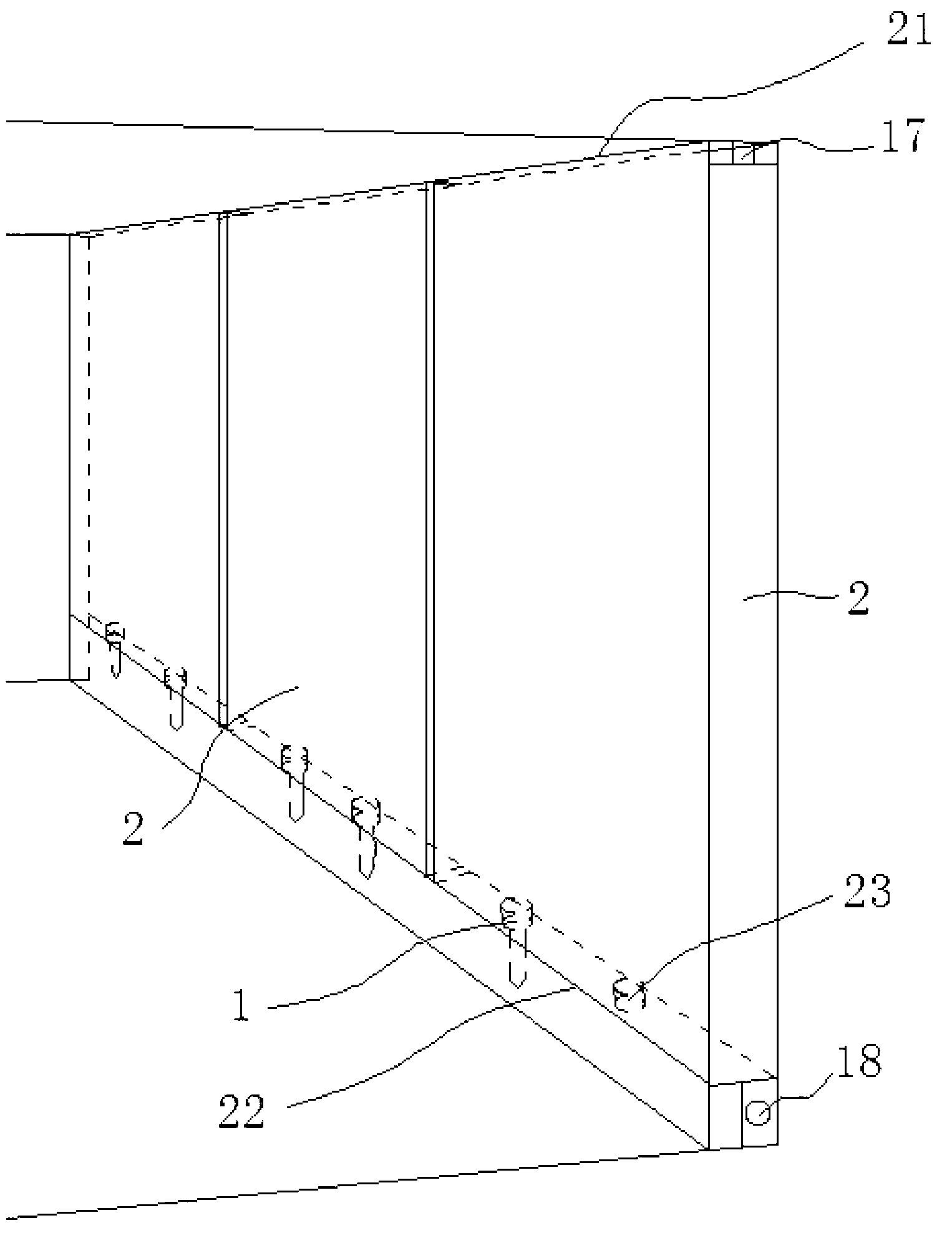

[0037] Examples, see Figure 1 to Figure 3 , the method for installing the concrete lightweight slab wall provided by the invention comprises the following steps:

[0038] (1) Prepare a jacking device 1 for pressing and fixing the wall panel 2 at the bottom of the wall foot of the wall panel 2. The jacking device 1 is composed of a base 11, an adjusting screw 12 and a nut 13, and the adjusting screw 12 runs through Set on the base 11, the nut 13 is screwed into the adjusting screw 12;

[0039] (2) Install 1 to 3 top glues 17 on the upper end surface 21 of the wall panel 2 facing the ceiling structural panel, and install 1 to 2 sets of the top fixing device 1 on the lower end surface 22 of the wall panel facing the floor structural panel ; The bottom of the wallboard is provided with a hole 23 that cooperates with the top fixing device 1, and the base 11 is inserted into the hole 23 and fixed.

[0040] (3) Use a wooden wedge to lift the lower end surface 22 of the wall panel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com