Vane of wind generating set

A technology of wind power generators and blades, which is applied to wind power generators, wind power generators consistent with the wind direction, and wind power generation. The effect of strong output and large sweeping area of the wind wheel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

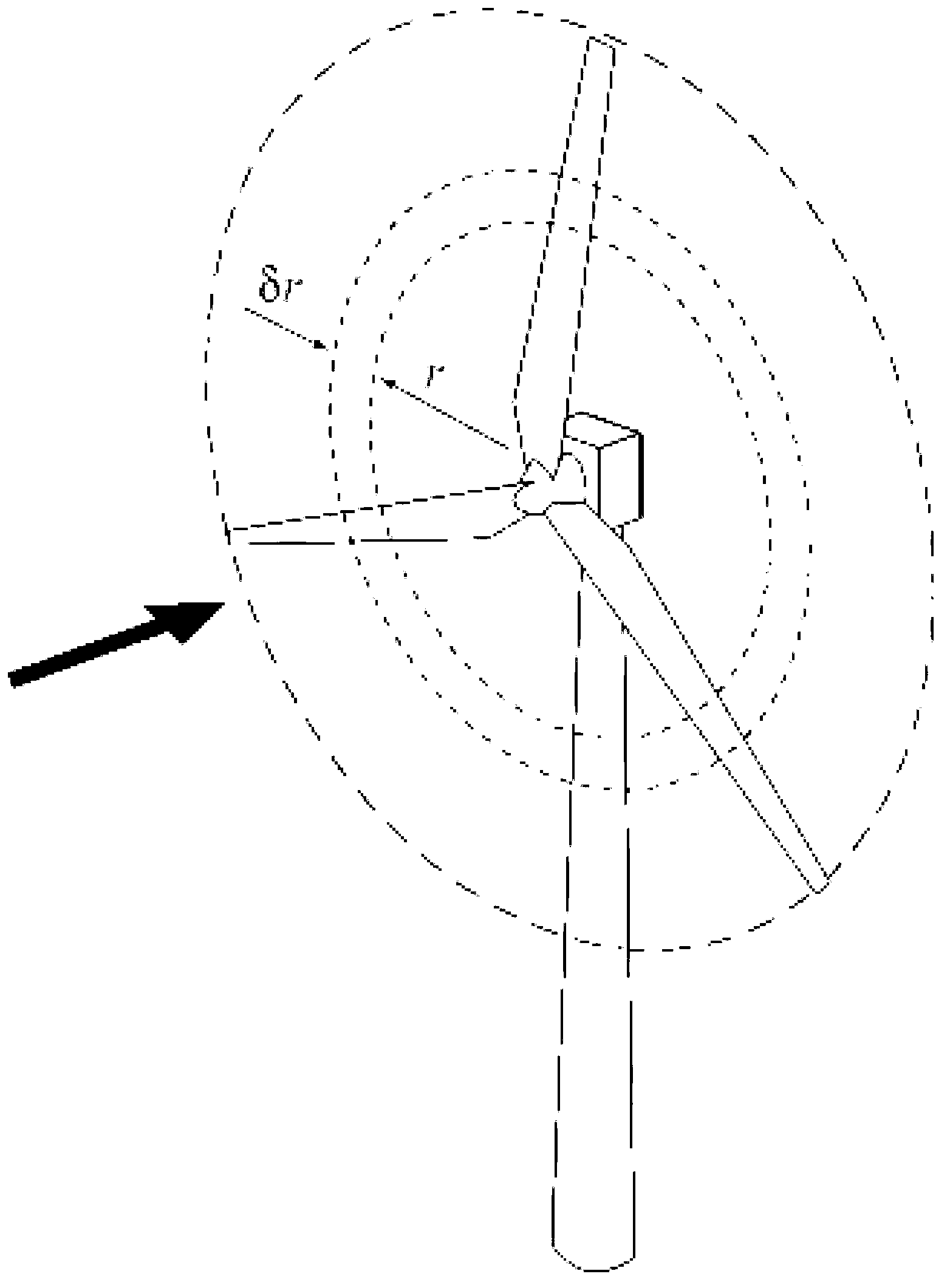

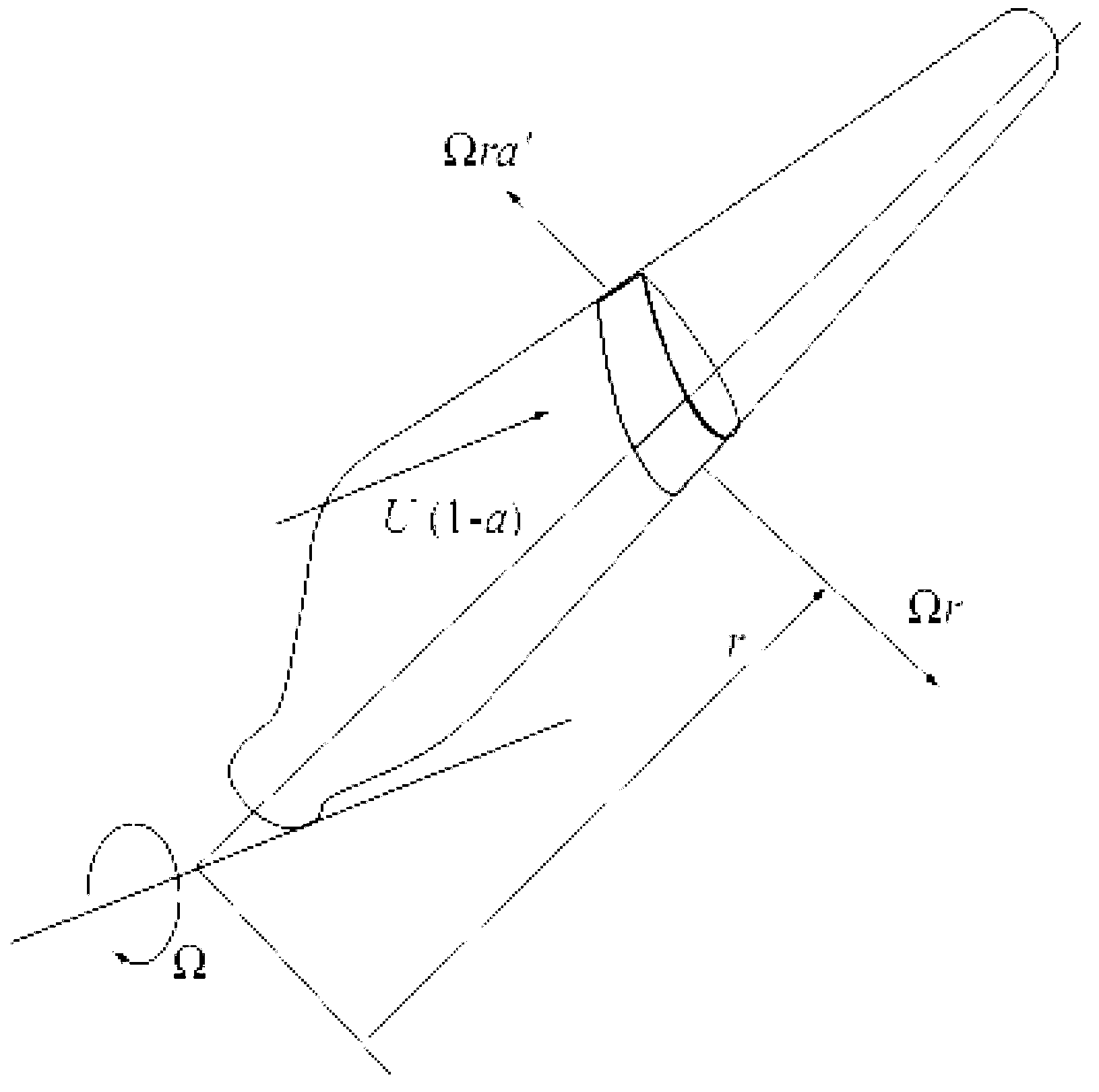

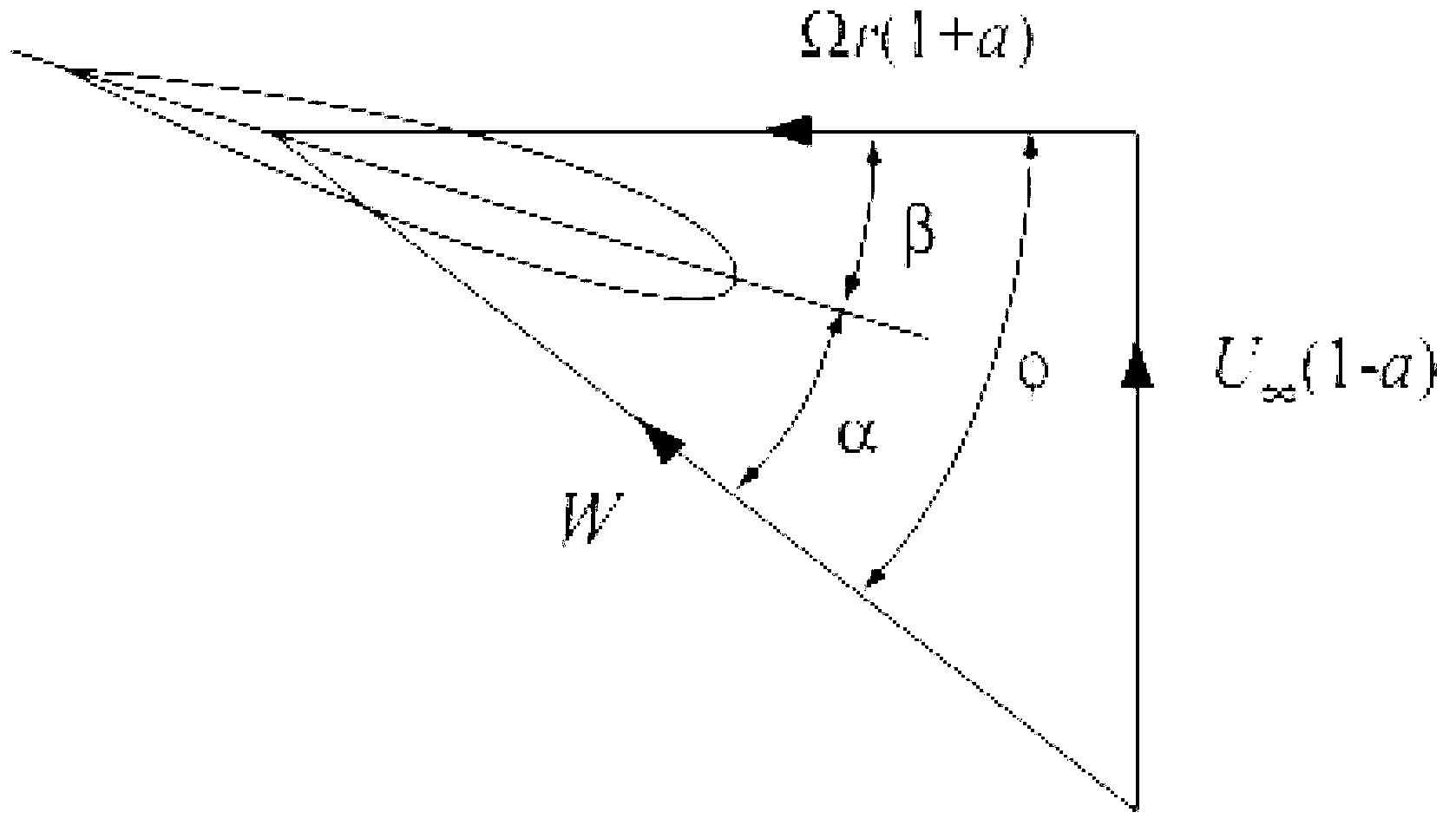

[0032] The present invention will be further described now in conjunction with accompanying drawing. These drawings are simplified schematic diagrams only to illustrate the basic structure of the present invention in a schematic way, so they only show the components relevant to the present invention.

[0033] A blade of a wind power generating set, the length of the blade is L=50.5m, and the radius of the rotor corresponding to the blade is R=52m.

[0034] The aerodynamic shape of the blade section at the position where the relative radius r / R of the wind rotor is 18.25-99.05% is:

[0035] 1) Use a modified airfoil with a relative thickness of 55.5-17.5%;

[0036] 2) The chord length is 3780-520mm;

[0037] 3) The twist angle relative to the chord line of the blade tip section is 11.75-1.05°;

[0038] 4) The lift coefficient of the design point is 1.35~1.02;

[0039] 5) The design Reynolds number is 1.0×10 6 ~8×10 6 .

[0040] The aerodynamic shape of the blade section ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com