Water-power-driving centrifugal pump

A hydraulic drive, centrifugal pump technology, applied in the direction of pumps, pump devices, non-variable pumps, etc., can solve the problems of fire extinguishing equipment can not take water to extinguish fire, fire equipment use restrictions, can not meet the water absorption fire extinguishing and other problems, to achieve light weight, structure The effect of compact and reasonable structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

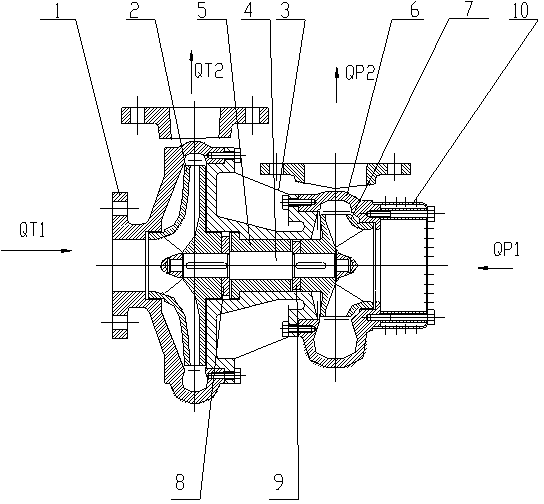

[0024] Such as figure 1 As shown, the hydraulically driven centrifugal pump of the present invention includes a centrifugal water pump and a water turbine, wherein the water turbine and the centrifugal water pump are coaxially installed.

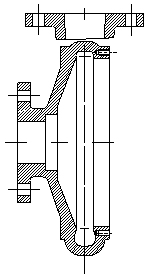

[0025] Wherein, the centrifugal water pump includes a pump body 1 , a pump cover 3 , an impeller 2 and a rotating shaft 4 . The structure of the pump body of the centrifugal water pump is as follows: figure 2 , image 3 shown.

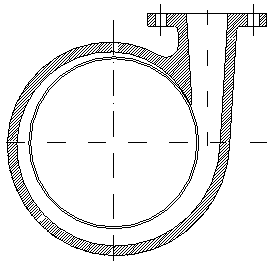

[0026] Wherein, the water turbine includes a pump cover, a volute 6 and a runner 7 . The volute structure of the turbine is as Figure 4 , Figure 5 shown.

[0027] The impeller of centrifugal water pump and the coaxial of water turbine are installed on the two ends of above-mentioned rotating shaft 4, and shaft sleeve 4 is equipped with in the middle part of rotating shaft 4, and its impeller is installed on rotating shaft 4 front ends through bearing 8. The running wheel 7 is installed on the rear end of t...

Embodiment 2

[0029] Working process of the present invention is as follows:

[0030] When working, the water driven by the power source enters the water turbine through the hydraulically driven water inlet QT1, and is discharged through the hydraulically driven water outlet QT2 to form a water cycle. The runner of the wheeled water turbine rotates, and then drives the rotating shaft of the present invention to work, and the rotating shaft drives the impeller of the centrifugal water pump to rotate, which is used as a water supply pump. The water supply of the centrifugal water pump is sucked through the pump water inlet QP1 and discharged from the pump water outlet QP2.

[0031] The hydraulic driving part of the water turbine can adopt a circulating water pump as a power source to provide the power of the present invention.

[0032] Driven by the water turbine, the centrifugal water pump can supply water to the fire fighting equipment.

[0033] The test data of hydraulic drive centrifuga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com