Bevel gear universal reducer

A universal reducer, bevel gear technology, applied in the direction of gear transmission, belt/chain/gear, coupling, etc., can solve the problem of increasing the weight, volume and cost of the mechanical system, the processing technology and reliability need to be improved, The connection between the shafts of the mechanical system is complex and other problems, to achieve the effect of simple structure, convenient manufacturing and processing, and reasonable support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

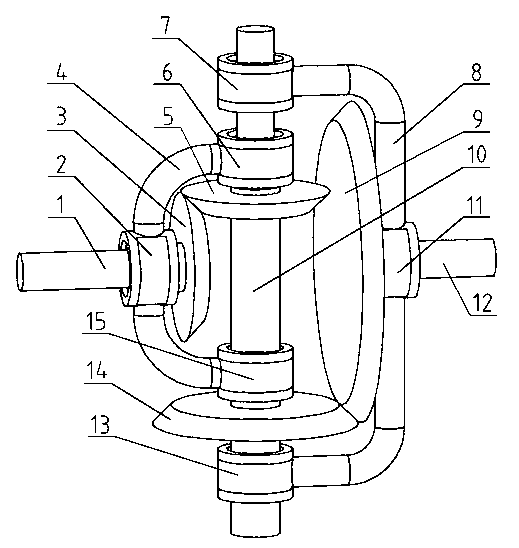

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

[0013] see figure 1 shown. The present invention consists of a driving shaft 1, a first rotating hinge 2, a driving shaft bevel gear 3, a driving shaft fork 4, an intermediate shaft first bevel gear 5, a second rotating hinge 6, a fifth rotating hinge 7, a driven shaft fork 8, The driven shaft bevel gear 9, the intermediate shaft 10, the fourth rotating hinge 11, the driven shaft 12, the sixth rotating hinge 13, the second bevel gear 14 of the intermediate shaft, and the third rotating hinge 15.

[0014] figure 1 Among them, the driving shaft 1 and the driven shaft 12 are respectively the power input shaft and the power output shaft of the whole mechanism, and the axes of the two shafts are located on the same plane. The driving shaft 1 is hinged with the driving shaft fork 4 through the first rotating hinge 2, so the driving shaft fork 4 can rotate relatively aro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com