Assembling, disassembling and locking mechanism for shear-resistance blocks of ultrahigh pressure large diameter deep sea environment simulating device

A deep-sea environment, simulation device technology, applied in pressure vessels, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problems of frequent replacement of locking devices, troublesome manual operation, high labor intensity, etc., to avoid manual operation and The effect of replacing defects, high work efficiency, convenient and flexible positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The specific embodiments of the present invention will be described below in conjunction with the drawings.

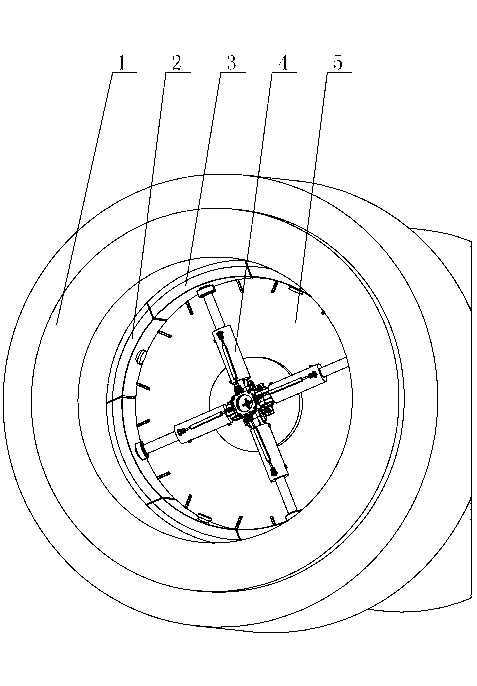

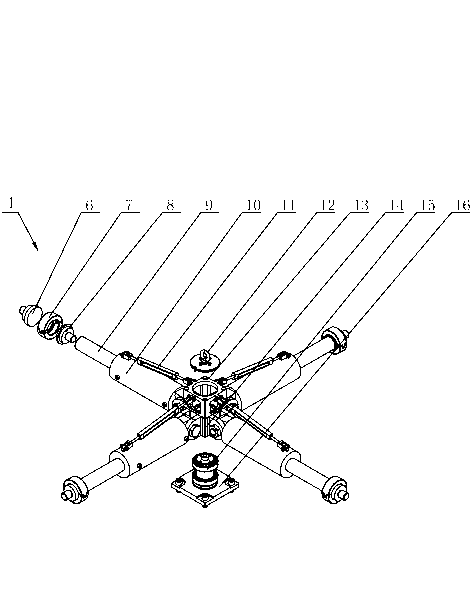

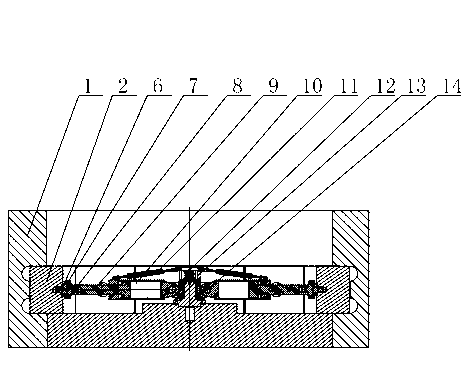

[0044] Such as figure 1 with figure 2 As shown, the ultra-high pressure large-diameter deep-sea environment simulation device of this embodiment has a shear block loading and unloading and locking mechanism, including a pressure cylinder 1, a cover 5 is provided on the top of the pressure cylinder 1, and an inner ring surface of the upper part of the pressure cylinder 1 is opened Shear groove 18, a shear block is installed on the cover 5. When the pressure cylinder 1 is pressurized, the shear block is clamped in the shear groove 18 of the pressure cylinder 1; the shear block is divided into oblique shear block 2 With the direct shear block 3, the oblique shear block 2 and the direct shear block 3 are installed at intervals on the top of the cover 5 and enclose a circle; the bearing seat 16 is installed in the middle of the cover 5, and also includes a cylinder seat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com