Method and device for implementing uniform flow of steam in boiler barrel

A technology of steam flow, steam flow, applied in combustion method, exhaust gas device, boiler drum/box header, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

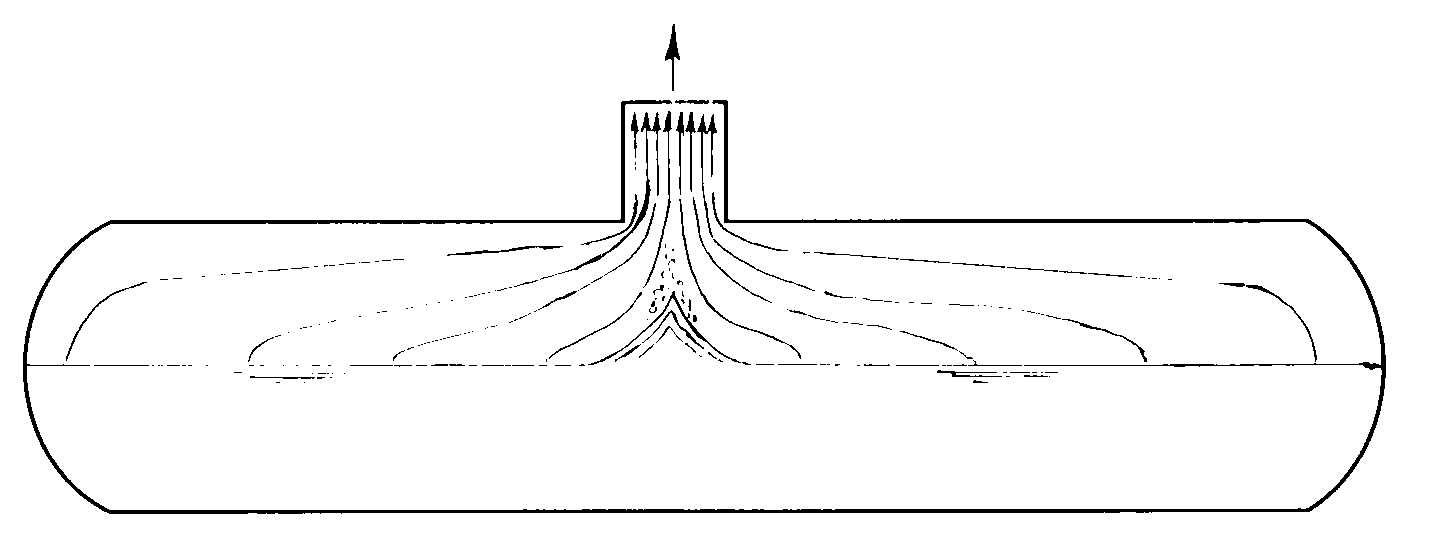

Problems solved by technology

Method used

Image

Examples

Embodiment 1

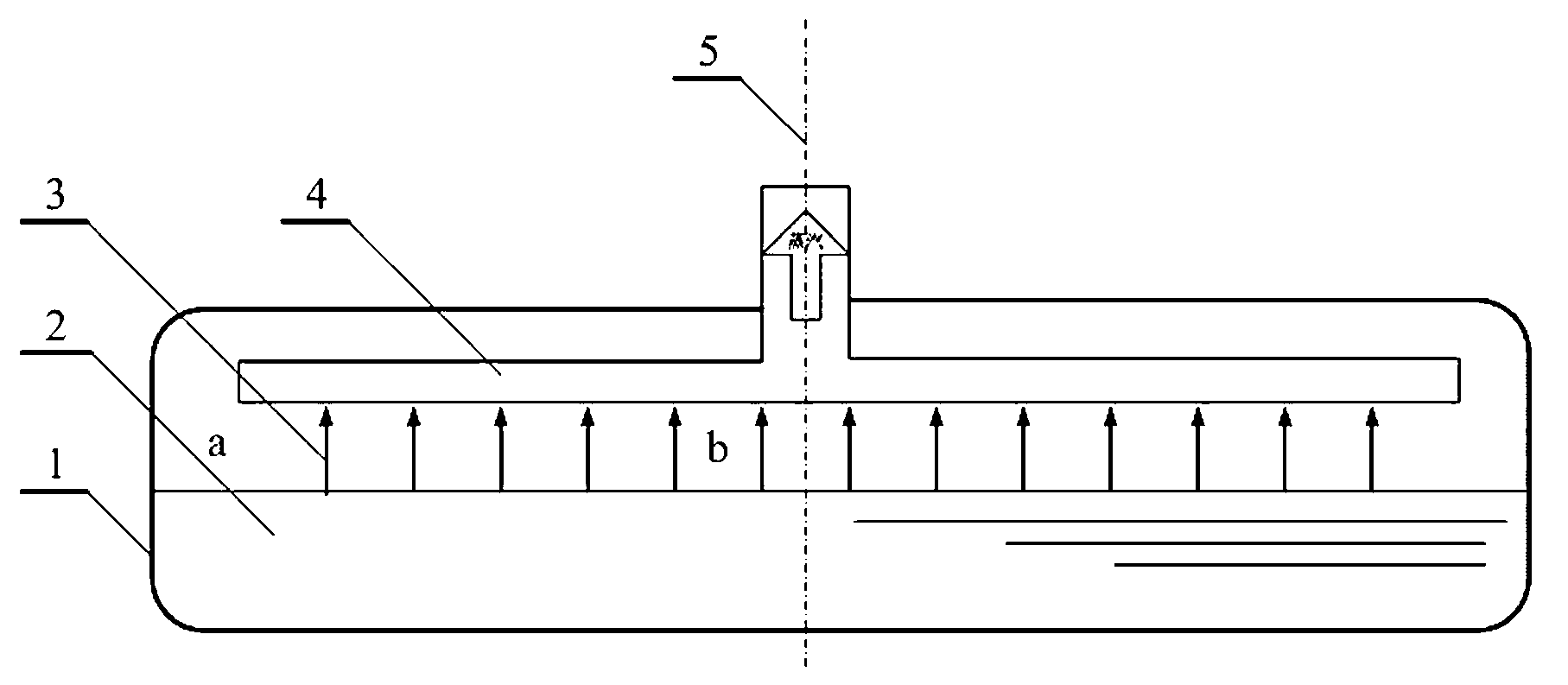

[0044] The steam generation equipment that the present embodiment relates to produces saturated steam, such as figure 2 with 3 As shown, its output steam volume D=10t / h, steam pressure P=1.6MPa.g,

[0045] The cross-section of the steam equalizing pipe is circular, the length L=20m, and the inner diameter is 0.08m. The number of segments of the equalizing pipe is n=12, the opening diameter of the equalizing pipe is d=0.0075m, and the total number of openings is 274.

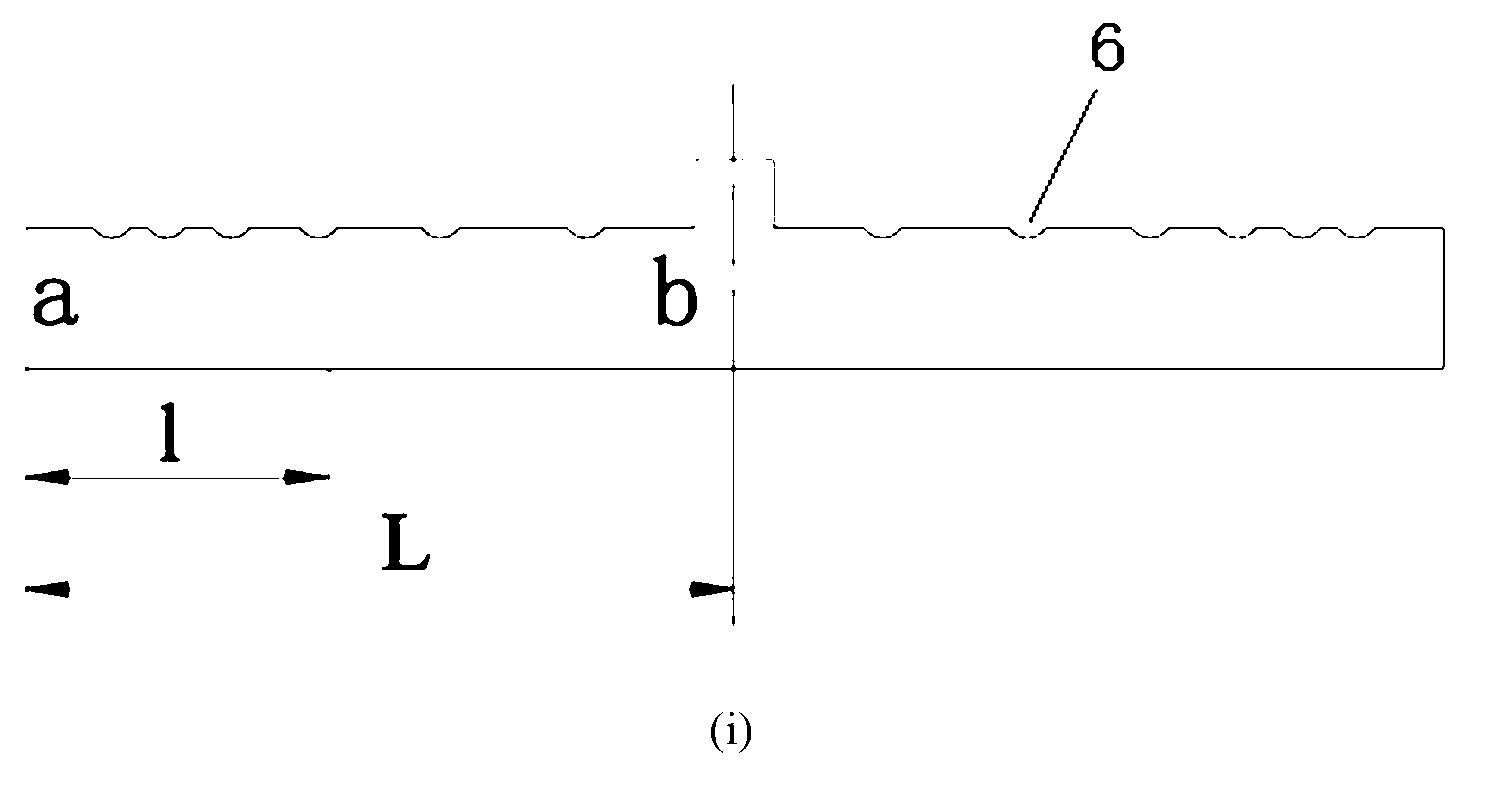

[0046] The horizontal part of the steam equalizing pipe is 0.10mm away from the upper edge of the inner wall of the drum, image 3 The opening of each segment is represented by a hole, the aperture d of the opening is the same, and the spacing S of the opening decreases gradually from both ends to the center line along the length of the flow equalizing tube.

[0047] From the end of the equalizing pipe to the middle, the pressure difference ΔP between the pressure of the steam in the drum and the steam pressur...

Embodiment 2

[0052] The steam generation equipment that the present embodiment relates to produces saturated steam, such as figure 2 with 4 As shown, its output steam volume D=10t / h, steam pressure P=1.6MPa.g,

[0053] The cross-section of the steam equalizing pipe is circular, the length L=20m, and the inner diameter is 0.08m. The number of segments of the equalizing pipe is n=12, and the total number of openings is 276.

[0054] The horizontal part of the steam equalizing pipe is 0.1m away from the upper edge of the inner wall of the drum, Figure 4 The opening of each section is represented by one hole, the number of openings in each section of flow equalizing pipe is 23, and the pitch S is 0.072m. Along the length of the flow equalizing tube, the diameter of the opening from both ends to the centerline gradually decreases.

[0055] From the end of the equalizing pipe to the middle, the pressure difference ΔP between the pressure of the steam in the drum and the steam pressure in th...

Embodiment 3

[0060] For the combustion equipment involved in this embodiment, the total flow of flue gas is V=168162nm 3 / h. The flue gas is drawn out with 7 flues. The length of each flue is 23.62m, the width is 0.58m, and the height is 2.33m. There are 9 rectangular openings along the length of each flue to introduce flue gas from the combustion chamber.

[0061] According to the calculation result of formula (5), the static pressure of the flue gas along the length of the flue is in the range of -0.7 to -125Pa. Along the length of the flue, the static pressure of the flue gas gradually decreases from the end to the outlet opening.

[0062] The area of the 9 openings along the length of the flue is shown in the table below:

[0063]

[0064] At the end of the flue, due to the small pressure difference between the pressure of the flue gas in the combustion chamber and the pressure of the flue gas in the flue, the area of the opening is larger, and at the outlet of the flue due t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com