Compact distributed coal powder boiler with SCR (selective catalytic reduction device)

A pulverized coal boiler, compact technology, applied in the field of pulverized coal boilers, can solve the problems of increased boiler footprint, high power consumption at the induced draft fan point, large steel consumption, etc., to prevent heat transfer crisis, prevent corrosion and The effect of sticking dirt, saving manufacturing cost and occupying area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

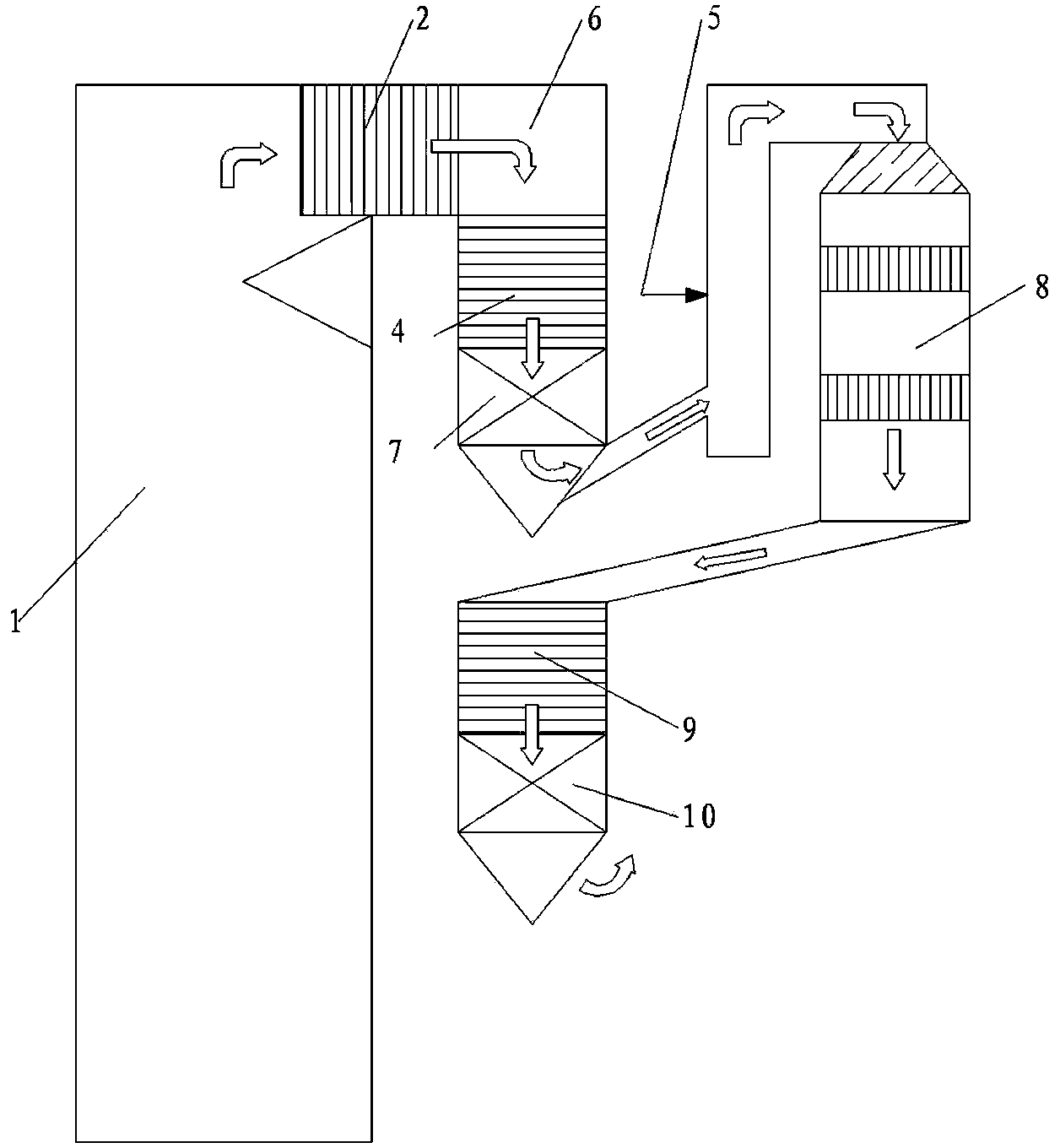

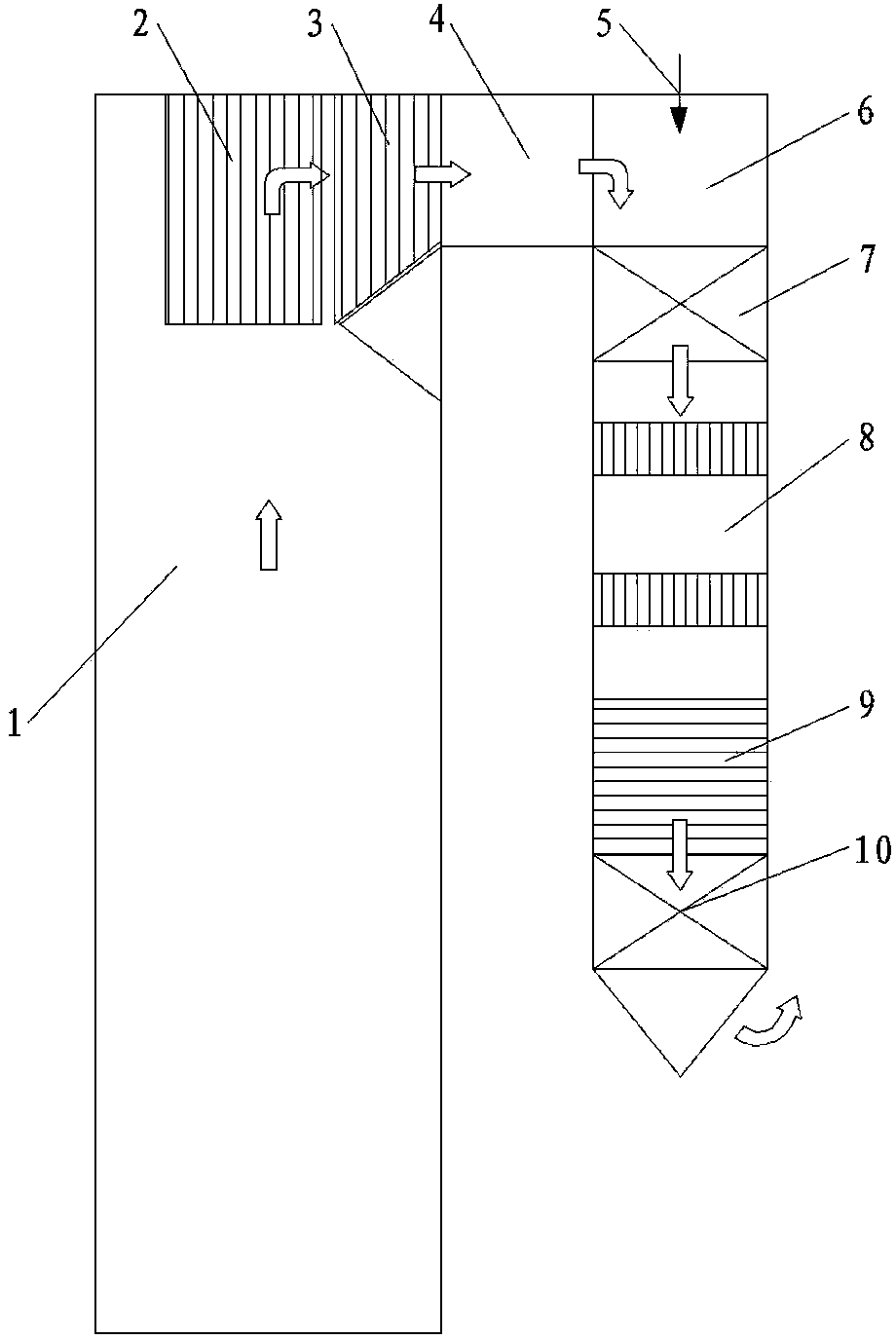

[0018] The specific structure of the compactly arranged pulverized coal boiler with SCR of the present invention will be further described below in conjunction with the accompanying drawings.

[0019] The structure of the compactly arranged pulverized coal boiler with SCR provided by the present invention is as follows figure 2 , the hot flue gas produced by combustion in the boiler furnace 1 flows through the convective superheater 3 between the panel superheater 2 located on the upper part of the boiler furnace 1 and the suspension tube of the water wall behind the boiler furnace 1, enters the horizontal flue, and passes through the horizontal A high-temperature economizer 4 with parallel vertical pipes installed in the flue, then enters the steering chamber 6, flows downward through the high-temperature air preheater 7, and the flue gas temperature drops to 380-400°C, and then enters the SCR reactor 8. Wherein the denitrification agent injection position 5 is set before th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com