Medical support detection method

A detection method and a technology of rotating brackets, which are applied in the direction of measuring devices, optical devices, and optical testing of flaws/defects, etc., can solve the problems of relatively high manufacturing process costs, slow manual detection, expensive equipment, etc., and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Various preferred embodiments of the invention are discussed below. However, those skilled in the art should understand that the detailed description herein is not intended to limit the protection scope of the present invention, and the present invention can also be realized through the modification of the following embodiments or other equivalent methods.

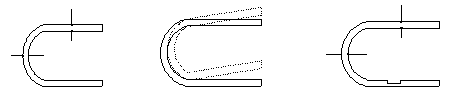

[0017] Defects such as contamination, incision failure, contact points, island-like defects, damage, corrosion spots, and deformation generally appear after stent processing. In a nutshell, as figure 1 As shown, common defects include shape defects as shown in a, geometric errors as shown in b, and boundary defects as shown in c.

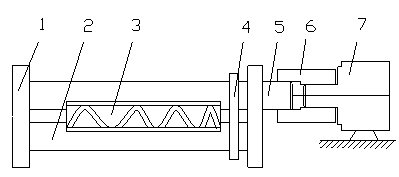

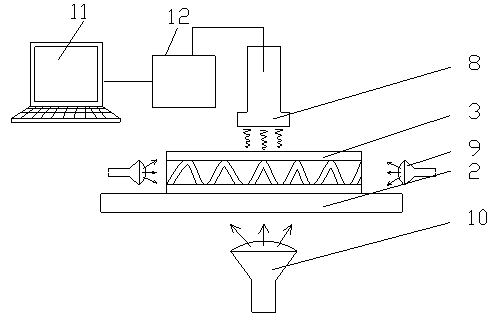

[0018] image 3 A device suitable for the detection method according to one embodiment of the present invention is shown. As shown in the figure, the device mainly includes: a roller device, a horizontal lighting source, a vertical lighting source, an electronic linear array CCD, a dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com