On-line monitoring system of transformer winding

A transformer winding and monitoring system technology, applied in the direction of electric/magnetic solid deformation measurement, instruments, measuring devices, etc., can solve the problems of winding heating, winding damage, accidental collision of transformers, vibration and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

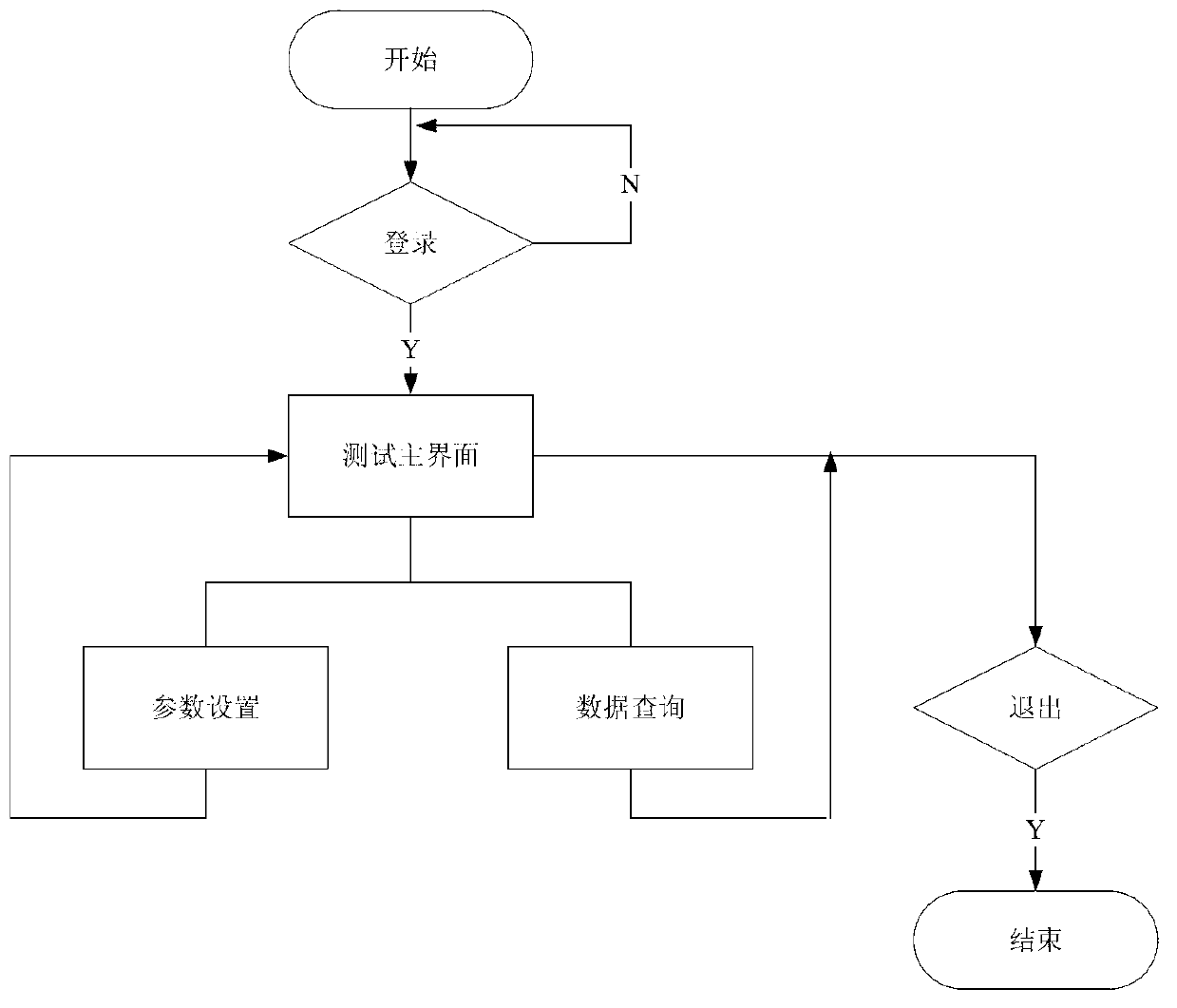

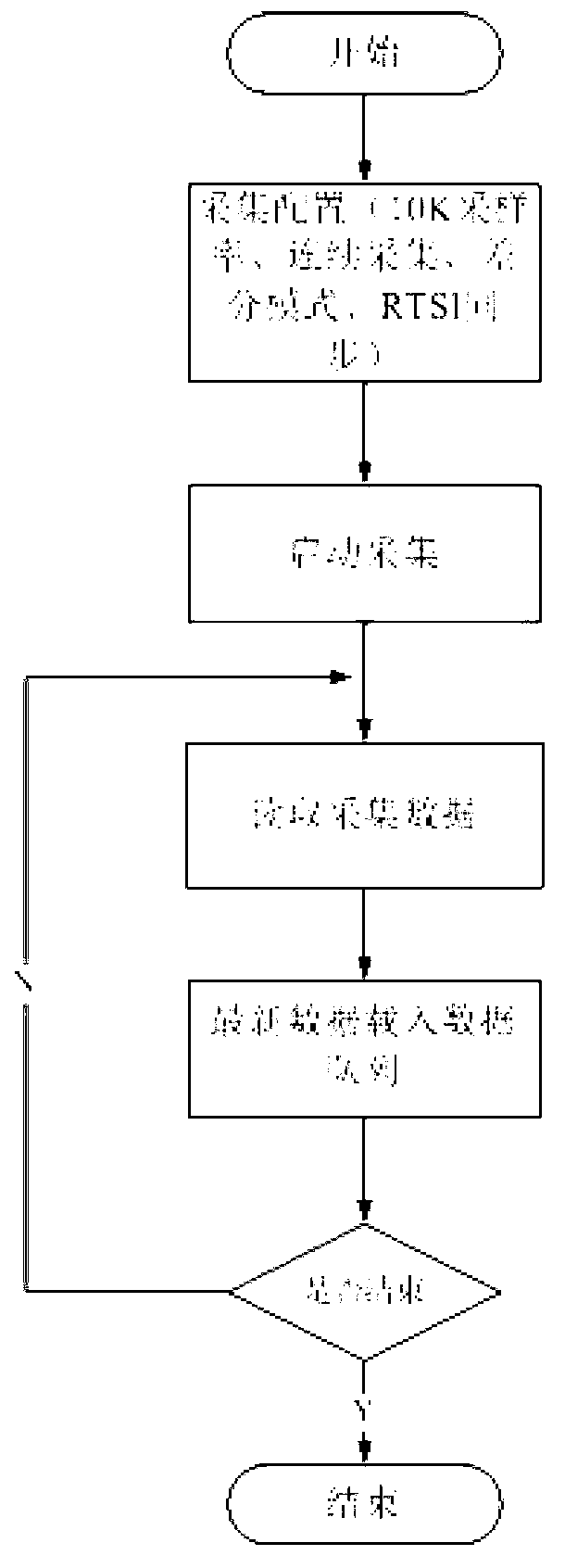

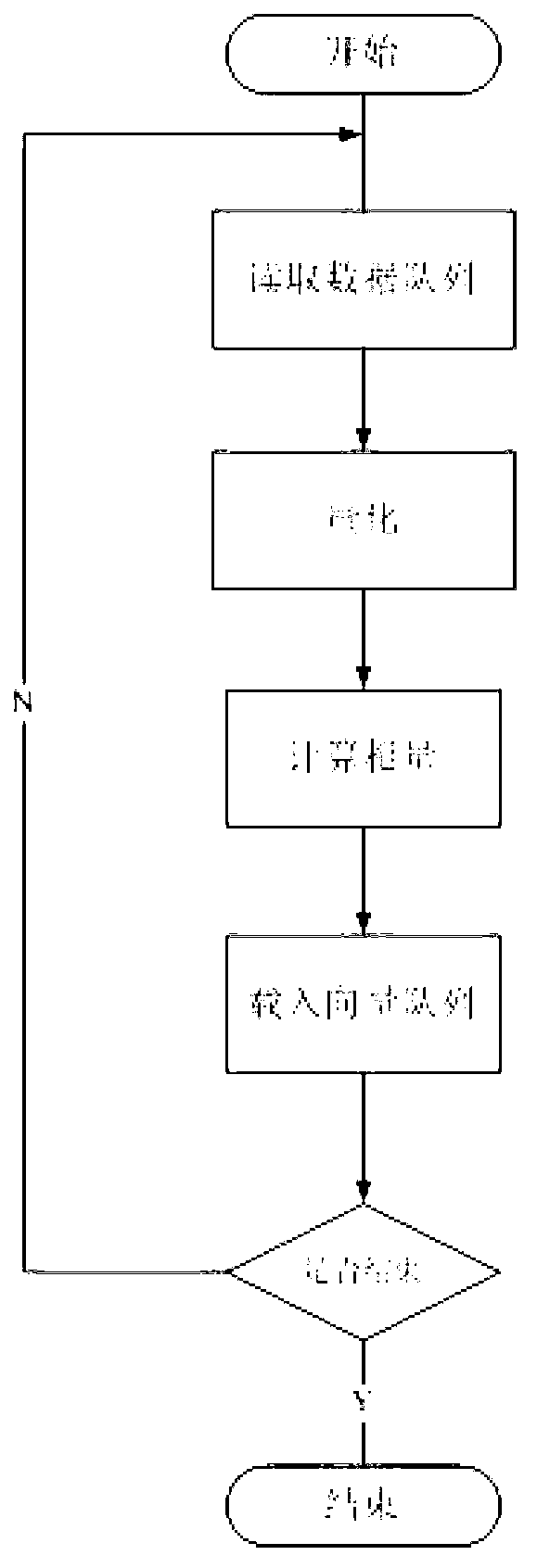

[0044] Taking a substation as an example, the monitoring system provided by the present invention will be further described in detail below. There are a total of two three-phase 35kV / 10kV step-down transformers in the substation, and the structure is star / delta. The main transformer provides voltage transformer (0-100V) and current transformer signal (0-5A) standard signals, and a total of 24 signals are given to the monitoring system. At the same time, the substation console provides transformer tap information through 485 bus communication.

[0045] The monitoring system needs to provide a monitoring cabinet, which will be combined with other control cabinets on site. The system needs to collect 24 channels of analog signals in real time, calculate and obtain the short-circuit reactance of each winding according to different tap positions, and give the variation of short-circuit reactance according to the vertical or horizontal ratio.

[0046] The monitoring system needs t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com