Water-cooled cable convenient in maintenance

A technology for water-cooled cables and cables, applied in the direction of insulated cables, cables, circuits, etc., can solve problems such as difficult disassembly and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Hereinafter, the present invention will be specifically introduced with reference to the drawings and specific embodiments.

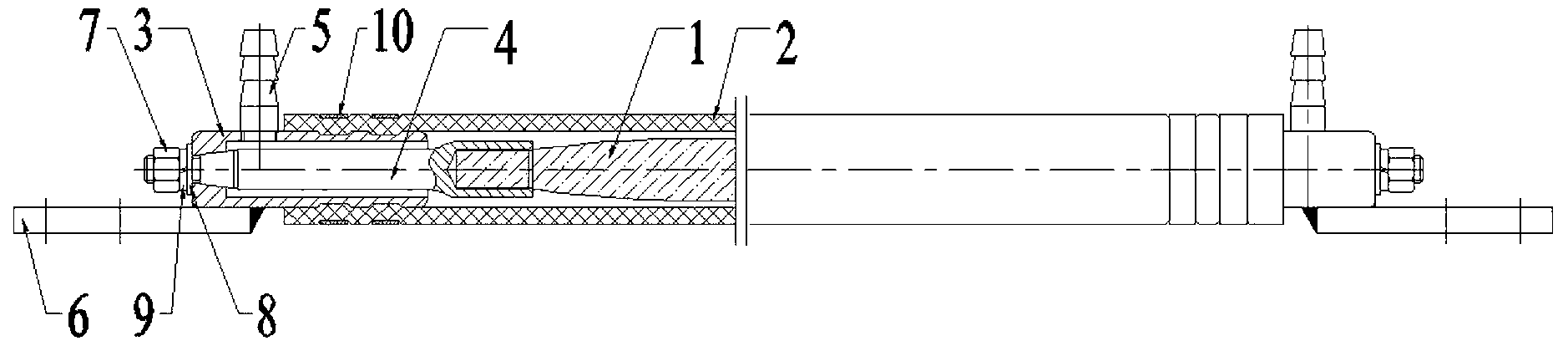

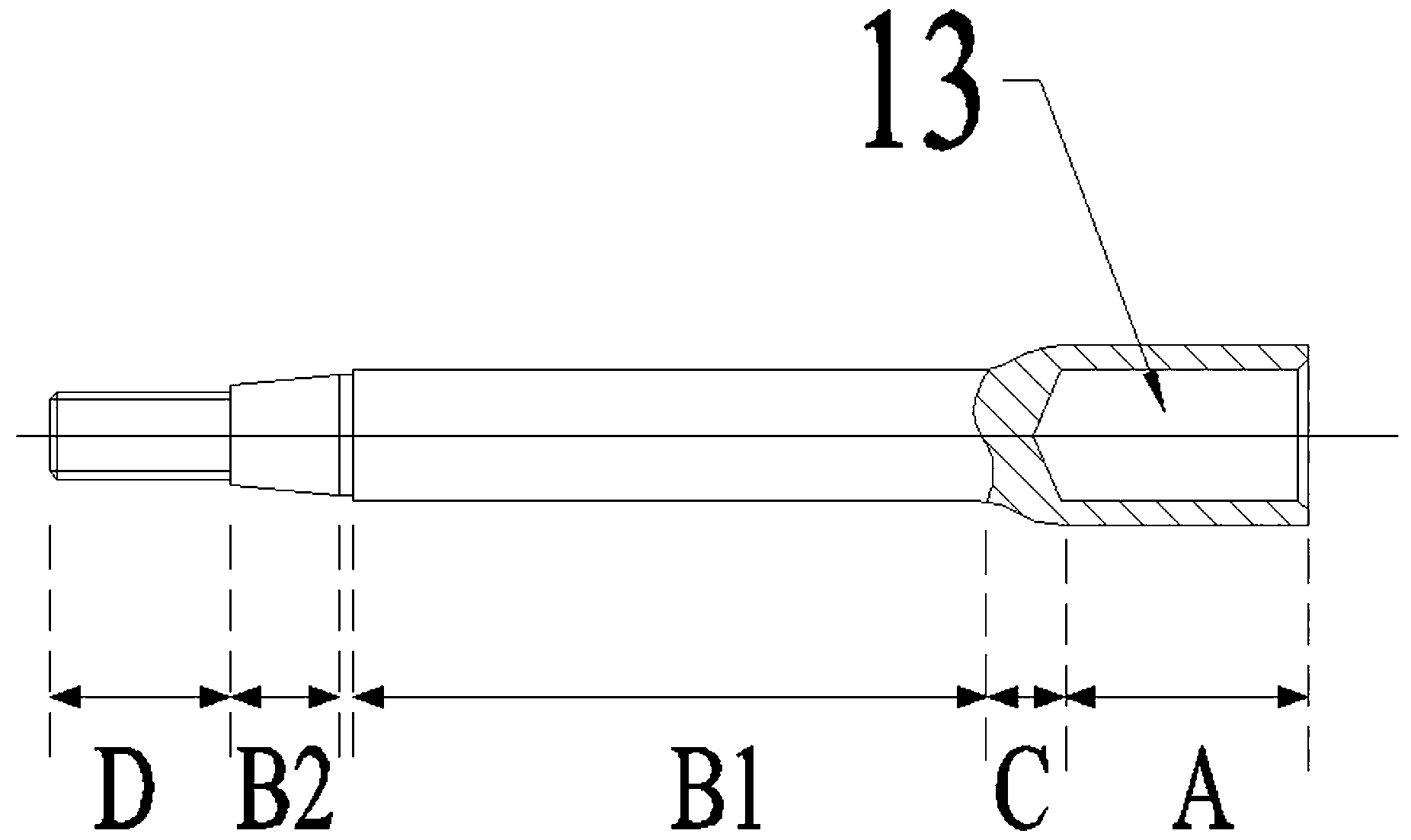

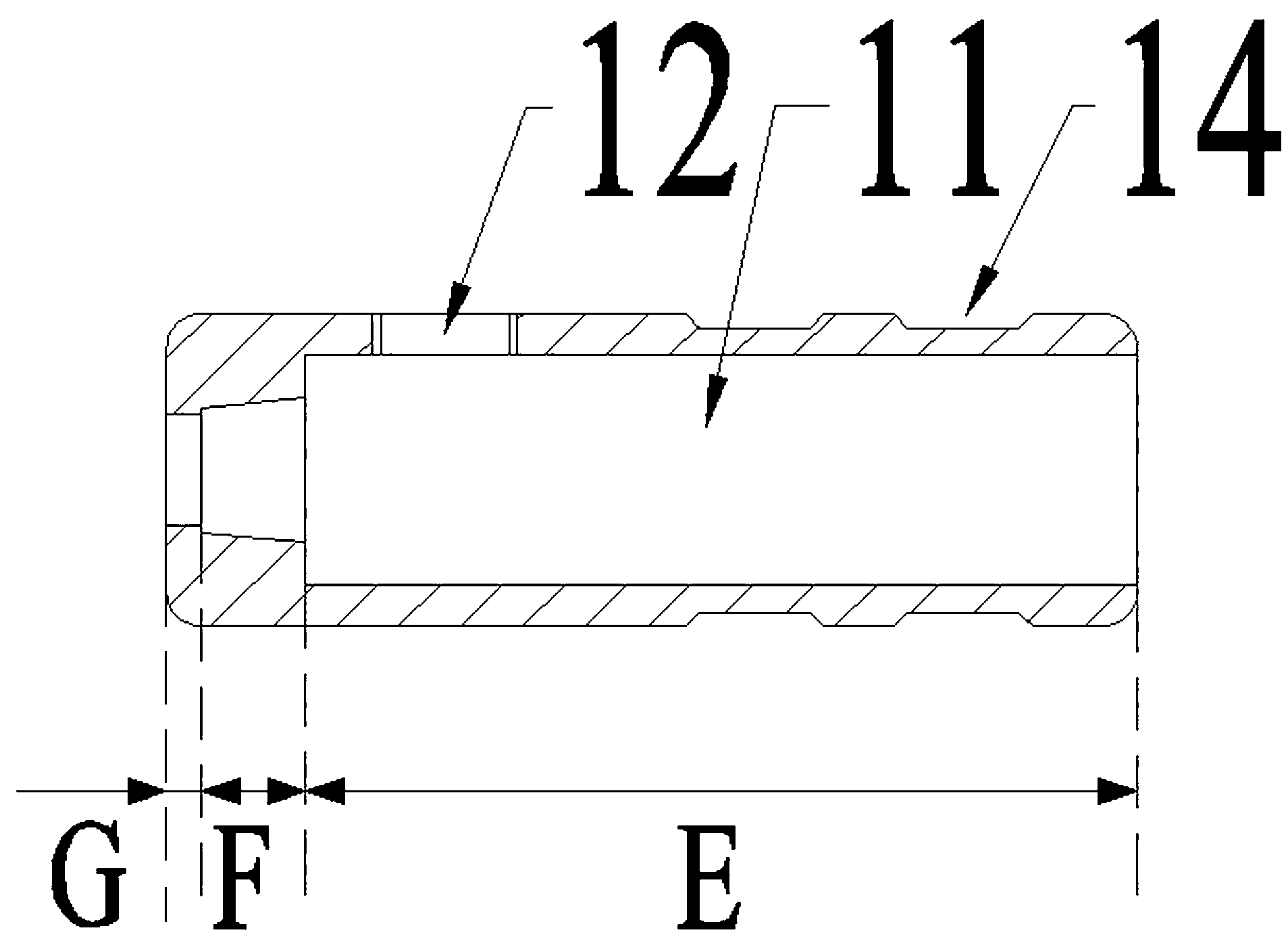

[0025] Reference Figure 1 to Figure 3 As shown, a water-cooled cable that is convenient for maintenance includes: conductive inner cable 1, cable sleeve 2, cable end 3, cable core rod 4, cable water nozzle 5, cable terminal plate 6, fixing nut 7 and washer assembly. As a preferred solution, the conductive inner cable 1 is a copper stranded wire, the cable sleeve 2 is a rubber sleeve, and the cable core 4, the cable end 3, and the cable terminal plate 6 are all made of metal conductor materials, specifically They can all be made of metallic copper.

[0026] The conductive inner cable 1 is arranged inside the cable sleeve 2. The length of the conductive inner cable 1 is shorter than the length of the cable sleeve 2, and both ends are retracted into the cable sleeve 2 and connected to the inner end of the cable core rod 4; The head 3 is a sleeve struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com